You operate with lithium battery packs in demanding B2B environments. Recognizing reverse polarity in batteries becomes critical for safety and operational efficiency. Battery damage can occur quickly with incorrect connections, especially in LiFePO4, NMC, LCO, LMO, and LTO packs.

Chemistry | Energy Density | Cycle Life | Safety Risk |

|---|---|---|---|

LiFePO4 | Moderate | High | Low |

NMC | High | Moderate | Moderate |

LCO | High | Low | High |

LMO | Moderate | Moderate | Moderate |

LTO | Low | Very High | Very Low |

Reverse polarity in batteries can cause electrical shorts, overheating, and system failures. You must prioritize prevention to protect battery assets and ensure long-term reliability.

Key Takeaways

Always check battery polarity before connecting to avoid damage and safety risks. Use clear labels and a multimeter to confirm correct connections.

Use matched cells and a reliable Battery Management System (BMS) to prevent reverse polarity caused by uneven cell discharge or wiring errors.

Combine mechanical and electronic protection methods, train your team well, and regularly inspect battery systems to ensure safe and reliable operation.

Reverse Polarity in Batteries

Identifying Reverse Polarity

Reverse polarity in batteries occurs when you swap the positive and negative terminals. In lithium battery packs, such as LiFePO4, NMC, LCO, LMO, and LTO, this condition usually results from incorrect connections during installation or maintenance. When you connect a battery or charger incorrectly, the negative terminal acts as positive and vice versa. This reversal disrupts the internal design of the battery, preventing full charging and reducing lifespan.

You can identify reverse polarity in batteries by checking for these signs:

Positive terminal marked with a plus sign (+), often connected to a red wire or VCC.

Negative terminal marked with a minus sign (-), usually connected to a black wire or ground (GND).

PCB silkscreen or copper layers with + and – markings near battery connector pads.

Unique part numbers or wiring configurations indicating reversed polarity.

Electrical symptoms such as short circuits, overheating, or battery failure after connection.

Tip: Always verify battery polarity before connecting to any system. Use a multimeter to confirm the voltage orientation if you suspect reverse polarity.

Why Reverse Polarity Matters

Reverse polarity in batteries poses a significant risk to your operations. When you reverse the terminals, the current flows against the battery’s internal design. This can cause immediate damage, including electrical shorts, overheating, and system failures. In lithium battery packs, reverse polarity can ruin the battery by reversing the internal plates, leading to severely diminished performance and reliability.

Reverse polarity is a critical safety concern for lithium battery packs. Manufacturers include protection features such as a 4.2 Amp polyswitch to limit maximum discharging current and safeguard against reverse polarity. The protection circuit board (PCB) also guards against overcharging, overdischarging, overdrain, and short circuits. These features maintain battery safety and extend operational life.

If you do not address reverse polarity in batteries, you risk:

Permanent damage to the battery chemistry and structure.

Reduced battery performance and lifespan.

Safety hazards, including overheating and fire.

Impractical operation, as the battery will no longer function correctly.

Note: The importance of reverse polarity protection cannot be overstated. You must implement regular checks and use proper connectors to prevent costly damage and ensure safety in B2B applications.

Battery Type | Polarity Protection | Typical Application | Safety Features |

|---|---|---|---|

Yes | Medical, Robotics, Security System | PCB, polyswitch | |

Yes | Infrastructure, Industrial | PCB, polyswitch | |

Yes | Consumer Electronics | PCB, polyswitch | |

Yes | Advanced Industrial | PCB, polyswitch |

Reverse polarity in batteries does not happen spontaneously. It requires external factors, such as incorrect charger connection or reversed charging system. You must train your team to recognize and prevent reverse polarity to maintain battery safety and performance.

For further reading on battery polarity and scientific facts, refer to Nature.

Causes, Dangers, and Safety Solutions

Incorrectly Connecting a Battery Charger

Incorrectly connecting a battery charger is one of the most common causes of reverse polarity in lithium battery packs. In industrial environments, you often work with complex systems where multiple battery chemistries—such as LiFePO4, NMC, LCO, LMO, and LTO—are deployed for critical applications like Medical, Robotics, Security System, Infrastructure, and Industrial systems. When you connect a charger with reversed leads, the battery terminals receive current in the wrong direction. This can immediately trigger reverse polarity, leading to system faults.

Industrial battery chargers sometimes include monitoring and alarm features that detect incorrect connections. These alarms help you identify and correct installation errors before they cause serious consequences. However, not all chargers have these features, and human error remains a significant risk. You must always verify the polarity before connecting any charger to a battery pack.

Reverse polarity can also result from mismatched cells within a battery pack. If you assemble a pack with cells of different capacities, the lower-capacity cells may become overdischarged during use. When this happens, current from higher-capacity cells can force the weaker cells into reverse polarity. A malfunctioning or improperly wired Battery Management System (BMS) that fails to stop discharge at the low voltage cutoff (LVC) increases this risk. Balancers only equalize voltage at a specific state of charge and cannot compensate for capacity differences.

Other contributing factors include:

Wiring shorts or thin wires causing heat buildup

Poor solder or crimp connections increasing resistance

Faults in balance wires or BMS electronics

Tip: Always use properly matched cells and a reliable BMS to minimize the risk of reverse polarity in your battery systems.

Dangers to Battery and Safety

Reverse polarity poses immediate and long-term dangers to both the battery and user safety. When you connect a battery incorrectly, you risk electrical shorts, overheating, and even fire. The battery chemistry can suffer irreversible damage, leading to a damaged battery that no longer holds charge or operates safely.

The potential damage extends beyond the battery itself. Connected devices, such as sensitive industrial controllers or medical equipment, may experience electrical faults or complete failure. In severe cases, reverse polarity can cause thermal runaway, resulting in fire or explosion. This creates a direct threat to user safety and can disrupt critical operations.

You must understand that reverse polarity can have serious consequences:

Permanent loss of battery capacity and performance

Increased risk of fire or explosion

Damage to expensive equipment and infrastructure

Safety hazards for personnel and facilities

Battery Chemistry | Risk of Reverse Polarity | Typical Application | Safety Features |

|---|---|---|---|

LiFePO4 | Low | Infrastructure, Industrial | PCB, BMS, polyswitch |

NMC | Moderate | Medical, Robotics, Security System | PCB, BMS, polyswitch |

LCO | High | Consumer Electronics | PCB, BMS, polyswitch |

LMO | Moderate | Industrial, Security System | PCB, BMS, polyswitch |

LTO | Very Low | Infrastructure, Industrial | PCB, BMS, polyswitch |

Note: The U.S. Consumer Product Safety Commission (CPSC) and standards such as ANSI/CAN/UL 2849:2020 and ANSI/CAN/UL 2272:2024 require reverse polarity tests and enhanced labeling to address electric shock and thermal runaway hazards. For more information, see CPSC lithium-ion battery safety standards.

Prevention and Solutions

You can prevent reverse polarity and its associated risks by implementing robust safety measures and protection against reverse polarity. Start by using only matched cells with the same capacity and internal resistance when assembling battery packs. Always install a high-quality BMS that reliably shuts off discharge at the low voltage cutoff. This ensures that no cell is driven into reverse polarity during operation.

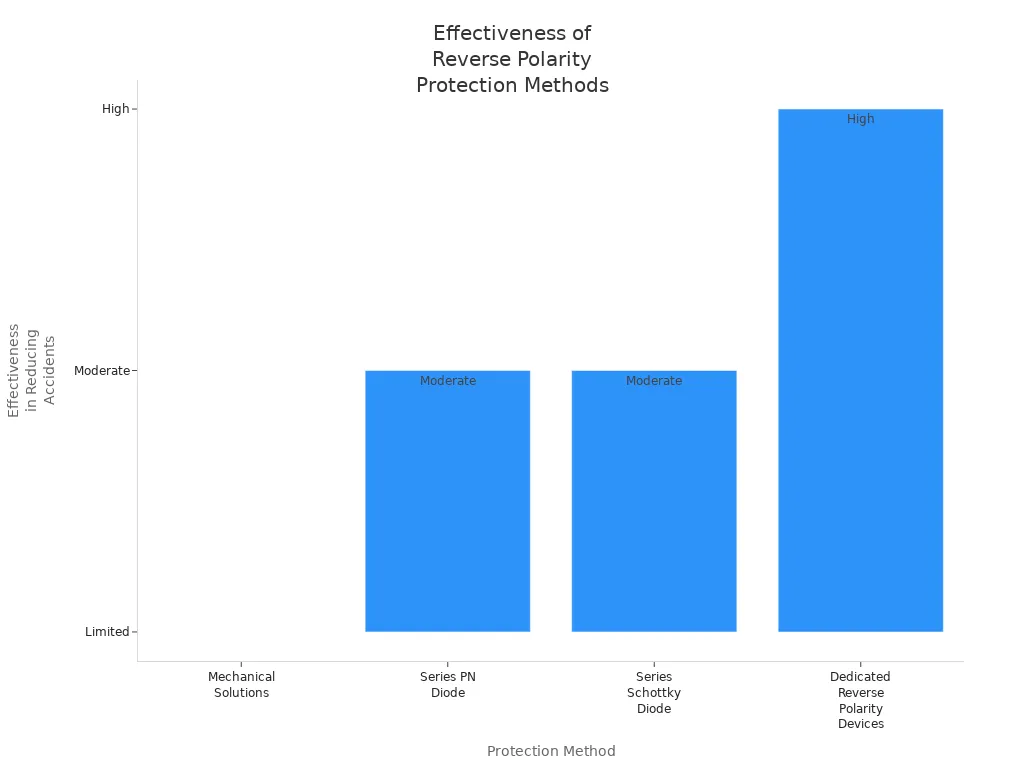

Protection against reverse polarity should include both mechanical and electronic solutions. Mechanical solutions, such as keyed connectors, help prevent incorrect insertion but may wear out over time. Electronic protection, such as series diodes or dedicated reverse polarity devices, offers more reliable and long-term safety.

Protection Method | Effectiveness in Reducing Battery-Related Accidents | Advantages | Limitations |

|---|---|---|---|

Mechanical Solutions | Moderate | Prevents incorrect insertion | Contact fatigue, reliability issues |

Series PN Diode | Moderate | Simple, low cost, resettable | High voltage drop, not ideal for high current systems |

Series Schottky Diode | Good (low current) | Lower voltage drop, less power consumption | Limited to low current, voltage drop may still be too high |

Dedicated Reverse Polarity Devices | High | Fast response, minimal voltage loss, cost-effective | Slightly higher cost at low current, best for high current packs |

To further enhance safety, follow these best practices:

Train your team to recognize correct battery polarity and use a multimeter for verification.

Use chargers and connectors with built-in polarity detection and alarms.

Regularly inspect wiring, connectors, and BMS functionality.

Label all battery terminals and connectors clearly.

⚠️ Alert: No single protection method eliminates all risks. Combine multiple safety features and follow industry standards to maximize user safety and minimize potential damage.

For custom consultation on battery safety solutions and protection against reverse polarity, contact our experts.

You must identify reverse polarity quickly to protect every battery in your operation. Regular checks and clear communication with your team reduce risks. Use this checklist for prevention:

Verify battery polarity before connection.

Train staff with structured, transparent communication.

FAQ

What should you do if you suspect reverse polarity in your lithium battery pack?

Immediately disconnect the battery. Use a multimeter to check polarity. Contact Large Power for a custom battery solution and further technical support.

How does reverse polarity protection differ among battery chemistries?

Chemistry | Reverse Polarity Risk | Typical Protection |

|---|---|---|

LiFePO4 | Low | PCB, BMS |

NMC | Moderate | PCB, BMS |

LCO | High | PCB, BMS |

LMO | Moderate | PCB, BMS |

LTO | Very Low | PCB, BMS |

Can Large Power provide custom solutions for industrial battery safety?

Yes. You can request a custom battery solution from Large Power for your industrial, medical, or robotics applications.