Designing safety into lithium batteries for medical devices demands careful attention to risks and regulatory oversight. You face unique safety considerations because battery failure can directly affect patient health. Recent reports show battery failure accounts for 1.42% of medical device failures, but hospital technicians observe that half of device issues relate to batteries.

Regulatory Body / Organization | Role / Scope of Oversight |

|---|---|

FDA | Regulates medical devices including batteries; requires compliance with recognized consensus standards for safety and performance before market entry. |

IEC | Provides battery safety standards such as IEC 62133 for lithium batteries. |

ANSI/AAMI | Develops standards for medical electrical equipment safety and performance, including battery requirements. |

Strong mechanical design and compliance with these standards help prevent battery failure and improve reliability.

Key Takeaways

Understand the risks of lithium batteries in medical devices. Overheating and short circuits can lead to dangerous failures. Address these hazards early in the design process.

Integrate built-in safety features like battery management systems and heat-resistant electrolytes. These technologies help prevent overcharging and thermal runaway, ensuring patient safety.

Follow strict safety standards such as IEC 62133 and ANSI/AAMI ES 60601-1. Compliance with these regulations is essential for market entry and reducing battery failure risks.

Implement rigorous quality assurance protocols throughout the battery lifecycle. Conduct thorough testing to ensure reliability and safety in medical applications.

Monitor battery performance post-market. Ongoing surveillance helps identify potential issues like overheating and ensures timely interventions to protect patients.

Part 1: Safety into Lithium Batteries

1.1 Application Risks in Medical Devices

You must understand the risks when you use lithium batteries in medical devices. These batteries can be volatile. Short circuits often cause overheating of the electrolyte, which can lead to a dangerous increase in pressure and even explosion.

Overheating is one of the main causes of lithium-ion battery failures. Excessive heat from faulty chargers or short circuits can damage the battery cell, leading to thermal runaway, where the heat promotes further chemical reactions, creating a disastrous spiral.

When you design safety into lithium batteries, you must consider several hazards:

Overcharging and overheating can lead to dangerous incidents.

Lithium-ion batteries degrade over time due to charge and discharge cycles.

Volatile electrolytes can release flammable gases when exposed to high temperatures or physical damage.

Ejection of batteries during incidents can spread fire or cause secondary ignitions.

There is a risk of reignition even after a fire is extinguished.

Thermal runaway can lead to fire or explosion.

A tragic incident on December 25, 2022, showed the severe consequences of battery failure. A fire caused by a lithium-ion battery in a heart device led to the deaths of a husband and his three-year-old son. This event highlights the importance of addressing battery hazards and fire hazards in medical devices.

You must follow a comprehensive design checklist to reduce risks:

Short circuits can occur due to breaches in cell compartments.

A short circuit creates a pathway for rapid electric current flow.

This rapid flow results in overheating of the electrolyte.

Overheating can lead to thermal runaway, causing battery failures and potential explosions.

Medical device manufacturers must address these risks early in the battery design process to protect patients and prevent device recalls.

Incident Type | Number of Injuries | Number of Deaths |

|---|---|---|

Medtronic HVAD | 6 | 1 |

Previous Recall | 2 | 1 |

Total Reports to FDA | N/A | 3000+ |

1.2 Built-in Safety Features

You can prevent many battery hazards by integrating safety features directly into the battery design. Medical device manufacturers use advanced technologies to monitor and control battery performance.

Feature | Description |

|---|---|

Battery Management Systems | Monitors and controls battery parameters to prevent overcharging, overheating, and short circuits. |

Solid-State Lithium-Ion | Safer and more stable, significantly reducing the risk of thermal runaway. |

Heat-Resistant Electrolytes | Can withstand higher temperatures, thus minimizing the risk of overheating. |

You should look for these built-in safety features:

Battery management systems anticipate failures before they occur, ensuring safety.

Solid-state lithium-ion batteries are safer and more stable, almost eliminating the chance of thermal runaway.

Heat-resistant electrolytes can withstand higher temperatures, which reduces the risk of overheating.

Manufacturers also use protection circuits to prevent overcharging, over-discharging, and short circuits. These features ensure safe operation of critical devices and maintain stable performance over long periods.

Thermal cutoffs monitor temperature thresholds and halt current flow when preset limits are reached, preventing overheating. Pressure relief mechanisms, such as deflagration panels, safely vent pressure during internal explosions, protecting surrounding equipment and personnel. Proper venting directs the force of a battery rupture away from critical areas, minimizing potential hazards.

Recent advancements in lithium-ion batteries provide more power and longer run times compared to older technologies. Solid-state batteries offer higher energy density and longer cycle life. Modern chemistries such as LiFePO4 and NMC deliver advanced safety features. Improved safety certifications (IEC62133, IEC60601, ISO 10535) and enhanced performance metrics have increased reliability, reducing service calls for dead batteries.

1.3 Mechanical Design for Safety

Mechanical design plays a key role in safety into lithium batteries for medical devices. You must select robust materials and smart engineering strategies to protect batteries from physical damage and short circuits.

Strategy | Description |

|---|---|

Advanced Chemistries | Use of silicon-anode Li-ion cells for increased capacity and solid-state batteries for enhanced stability and energy density. |

Optimal Cell Arrangement | Implementation of series/parallel combinations and vertical stacking of prismatic cells to save space. |

Energy Management | Incorporation of low-power electronics and sleep modes to optimize energy usage. |

Smart Battery Management Systems | Systems that monitor and balance cells, prevent overcharging, and manage faults for improved safety. |

Thermal Management | Utilization of phase-change polymers, graphene layers, and ceramic separators to enhance heat dissipation and safety. |

Robust Materials | Adoption of aerospace-grade aluminum and PEEK polymers to provide shock absorption and durability. |

You should use protective enclosures to physically shield the battery and control thermal conditions. Adherence to IEC and ASTM safety standards ensures the battery design can withstand shock and vibration, reducing the risk of physical damage. Advanced monitoring systems track cell voltages to prevent overcharging and overdischarging, which are critical for avoiding dangerous battery failures.

Medical device manufacturers face several challenges:

Challenge Type | Description |

|---|---|

Adhering to safety standards | Manufacturers must comply with various safety standards such as ANSI/AAMI ES 60601-1 and IEC standards. |

Minimizing battery tampering risks | Devices should be designed to prevent the use of unapproved batteries and chargers. |

Proper storage and handling | Ensuring that batteries are stored correctly to avoid thermal runaway and other hazards. |

Addressing thermal runaway potential | Implementing design features to minimize the risk of thermal events that can lead to injury or damage. |

You must balance battery performance and safety. Medical devices require batteries with high capacity for long operation periods without replacements. Some devices need quick power delivery, so you must balance capacity and power density. Manufacturers leverage past experiences, understand battery chemistry, and collaborate with battery assembly experts to enhance safety into lithium batteries.

Part 2: Safety Standards and Compliance

2.1 Key Safety Standards (IEC 62133, ANSI/AAMI ES 60601-1)

You must understand the safety standards that guide the design and approval of lithium batteries for medical devices. These standards help you prevent hazards such as fire, explosion, and battery failure. The FDA requires you to comply with both IEC 62133 and ANSI/AAMI ES 60601-1 when you develop batteries for medical devices. IEC 62133 focuses on battery safety under normal operating conditions. ANSI/AAMI ES 60601-1 covers risk management and essential performance for medical electrical equipment.

Aspect | IEC 62133 | ANSI/AAMI ES 60601-1 |

|---|---|---|

Scope | Secondary cells and batteries containing alkaline or other non-acid electrolytes | Comprehensive standards for medical electrical equipment, including battery-operated devices |

Risk Management | General safety requirements for battery use | Includes a risk management assessment model and essential performance framework |

Compliance Requirements | Specifies requirements and tests for safe battery use | Requires compliance with IEC 60086-4 for primary batteries and IEC 62133 for rechargeable batteries |

Production Standards | Focus on battery safety under intended operating conditions | Guidelines for minimizing product malfunctions and ensuring operator and patient safety |

Supply Chain Management | Not specifically addressed | Recommendations for documentation and traceability in supply chain management |

You must meet these reliability standards to gain FDA approval for your medical devices. High compliance rates with IEC 62133 and ANSI/AAMI ES 60601-1 increase your chances of market entry and reduce risks of battery failure.

2.2 Certifications for Medical Devices and Batteries

Certifications prove that your batteries meet global safety standards. You need to secure several certifications before you ship batteries for medical devices.

Certification | Description | Market Applicability |

|---|---|---|

UN38.3 | Transportation safety test standard for lithium batteries | International |

Confirms compliance with EU safety, health, and environmental standards | European Economic Area (EEA) | |

RoHS Certification | Ensures compliance with environmental safety standards, restricting hazardous substances | Global |

You must obtain CE Certification for access to the European market. RoHS Certification helps you reduce environmental hazards. UN38.3 is necessary for safe transport and handling of batteries, especially to prevent fire or explosion during shipping.

2.3 Regulatory Requirements for Medical Implantable Devices

You must follow strict regulatory requirements for batteries in implantable medical devices. The FDA enforces rigorous safety and reliability standards. In the United States, you need UL 1642, UL 2054, and UN/DOT 38.3 certifications. Europe requires CE Marking, EN Standards, and IEC 62619. China enforces GB 31241-2014 and CCC certifications.

Region | Certification Standards | Key Requirements |

|---|---|---|

United States | UL 1642, UL 2054, UN/DOT 38.3, FCC, OSHA | Rigorous safety testing, transportation safety, compliance with communication and safety regulations. |

Europe | CE Marking, EN Standards, UN 38.3, IEC 62619, Battery Passport | Compliance with health, safety, environmental requirements, and documentation for market access. |

China | GB 31241-2014, GB/T 31485, CCC, UN 38.3 | National standards for performance and safety, compulsory certification, and adherence to transport regulations. |

You must stay updated on regulatory changes. For example, starting January 1, 2026, lithium batteries packed with equipment must have a state of charge of 30% or less. New packaging rules and classification systems help you improve safety and reliability standards for medical devices.

Part 3: Reliability and Testing

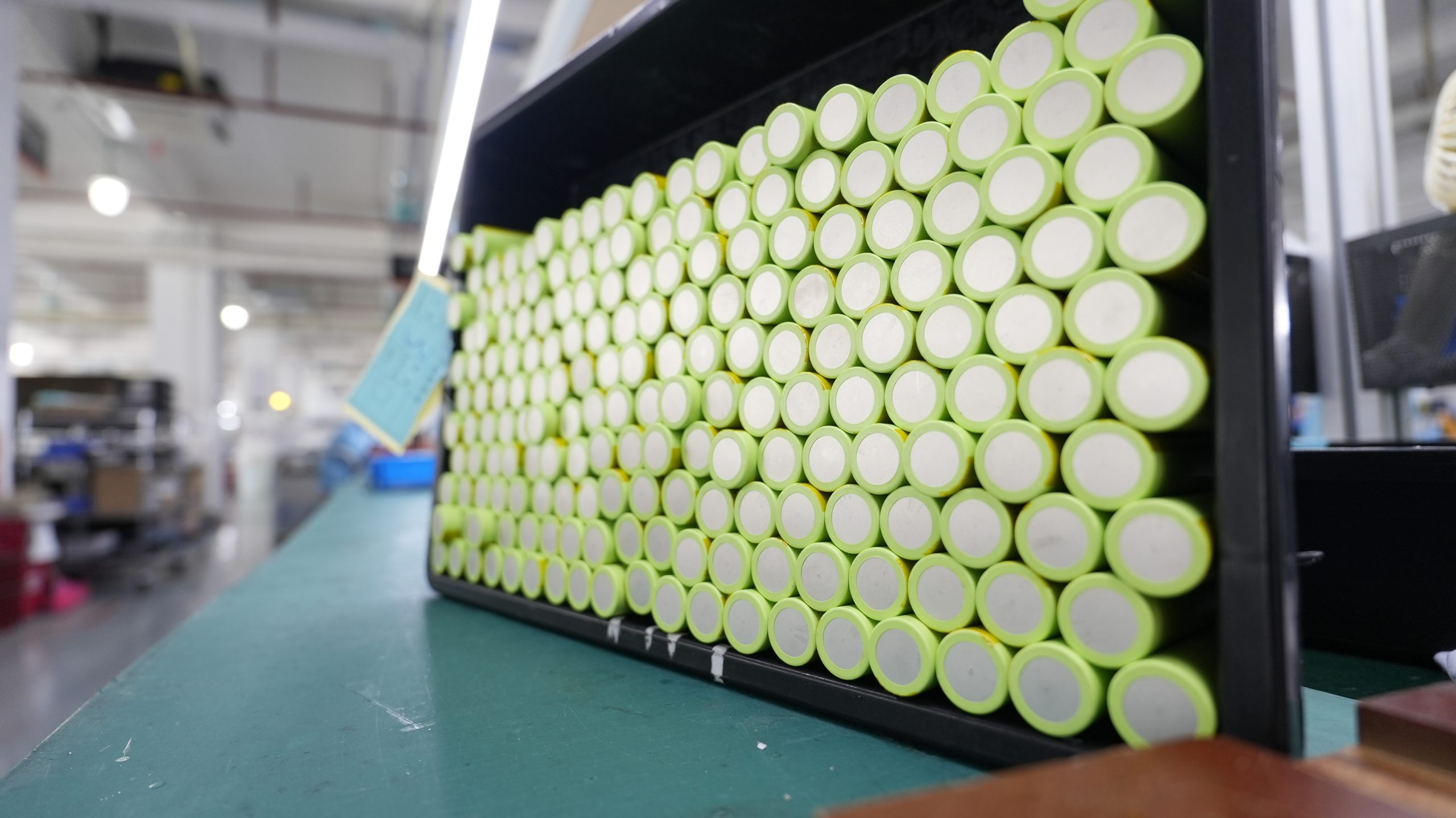

3.1 Quality Assurance for Batteries

You need rigorous quality assurance protocols to ensure the reliability of lithium battery packs in medical devices. You must apply a holistic approach throughout the product lifecycle. Supplier qualifications should meet standards like ISO 9001 and ISO 13485. You must conduct electrical safety, temperature, shock, and vibration tests. Ongoing quality assurance includes a complaint management system to address issues quickly. Medical device manufacturers rely on strict regulatory standards, unlike consumer electronics. You must keep batteries free from contaminants and safe for direct patient contact. Reliability is critical because battery failure can cause severe consequences, including fire or thermal runaway. You must design batteries for long lifespan and consistent performance.

Holistic quality approach across the lifecycle

Supplier qualification (ISO 9001, ISO 13485)

Rigorous electrical, thermal, and mechanical testing

Complaint management for post-market issues

3.2 Environmental and Endurance Testing

You must test batteries for resilience to environmental hazards. Battery safety testing ensures patient safety and device reliability. Regulatory compliance with FDA, ISO, and IEC standards is required. You must assess batteries for temperature fluctuations, humidity, and physical shocks. Long-term performance verification helps you identify degradation issues, which is critical for devices that operate for years. Risk mitigation reduces liability and builds trust in your products.

Metric | Description |

|---|---|

Capacity Fade | Gradual decrease in battery capacity over its usable life, affecting time between charges. |

Cycle Life | Number of charge-discharge cycles before capacity falls to 80% of its original value. |

Depth-of-Discharge (DoD) | Cycling conditions that affect battery longevity, with medical applications typically requiring 500 to 1,000 cycles at 100% DoD. |

End-of-Charge Voltage (EoCV) | Maximum voltage for charging, typically around 4.1V, with a discharge limit of 2.7V. |

Retained Capacity | Medical batteries must maintain at least 80% of initial capacity after specified cycles. |

You must design lithium-ion batteries to withstand thermal hazards and prevent runaway events. Environmental considerations are more stringent for medical batteries, which often contain hazardous materials that require proper disposal.

3.3 Post-Market Surveillance

You must monitor batteries after they enter the market. Post-market surveillance is crucial for safety and performance. Regulatory frameworks guide this process and require evidence-based assessments. You must track device measurements to enhance reliability. Safety concerns include overheating, battery failure, fire, and thermal runaway hazards. Health care IT professionals help you monitor and address these risks. You must understand battery aging and replacement policies to prevent failures. Some implant batteries provide less than half the estimated runtime, which can result in physical harm to patients. You must design clear replacement guidelines and improve traceability.

Ongoing monitoring for safety and performance

Traceability of device measurements

Addressing overheating, fire, and thermal runaway hazards

Clear battery replacement policies

You must integrate safety and reliability into lithium batteries for medical devices from the earliest stages of design. When you follow strict safety standards and use robust mechanical design, you reduce risks and improve long-lasting performance.

Description | |

|---|---|

Higher Reliability | Batteries in medical devices meet high standards for safety and reliability. |

Longer Lifetimes | |

Compliance with Standards | Ensures batteries are safe and effective for healthcare environments. |

The implementation of ISO 13485 requires you to maintain strong controls and documentation, which leads to better reliability and safety. Continuous improvement in battery technology helps you adapt to new regulations and deliver safer products.

FAQ

What makes lithium battery packs suitable for medical implantable devices?

You benefit from lithium battery packs because they offer high energy density, stable platform voltage, and long cycle life. These features support the strict requirements of medical implantable devices, ensuring reliable operation and patient safety.

How do medical device manufacturers ensure battery safety in medical implantable devices?

You must follow strict safety standards and use advanced chemistries like LiFePO4 or NMC. Medical device manufacturers conduct rigorous testing and quality assurance to prevent failures in medical implantable devices.

Why is cycle life important for batteries in medical implantable devices?

You rely on long cycle life to reduce replacement frequency and minimize patient risk. Medical implantable devices require batteries that maintain performance over hundreds of cycles, supporting continuous operation and reliability.

What testing protocols apply to lithium battery packs for medical implantable devices?

You must use environmental and endurance testing to verify battery resilience. Medical implantable devices undergo temperature, shock, and vibration tests to ensure lithium battery packs meet regulatory standards and perform safely in real-world conditions.

How do you select the right lithium battery chemistry for medical implantable devices?

You evaluate platform voltage, energy density, and cycle life. Medical implantable devices often use LiFePO4 for safety or NMC for higher energy density. You choose based on device requirements and regulatory compliance.