You rely on battery safety when designing portable medical devices. Lithium-ion packs present unique challenges in medical environments, making Safety Testing essential. You must meet rigorous standards like IEC 62133, which covers chemical, electrical, and mechanical hazards. Manufacturers and healthcare professionals share responsibility for maintaining safety and reliability in every medical application.

Key Takeaways

Understand the risks of lithium-ion batteries in medical devices. Proper battery selection and safety testing can reduce patient risk and ensure device reliability.

Follow IEC 62133 standards for battery safety. Compliance with these standards helps achieve certification and supports ongoing regulatory requirements.

Implement robust design and maintenance practices. Regular checks and timely battery replacements enhance safety and prolong device life.

Part1: Medical Device Battery Risks

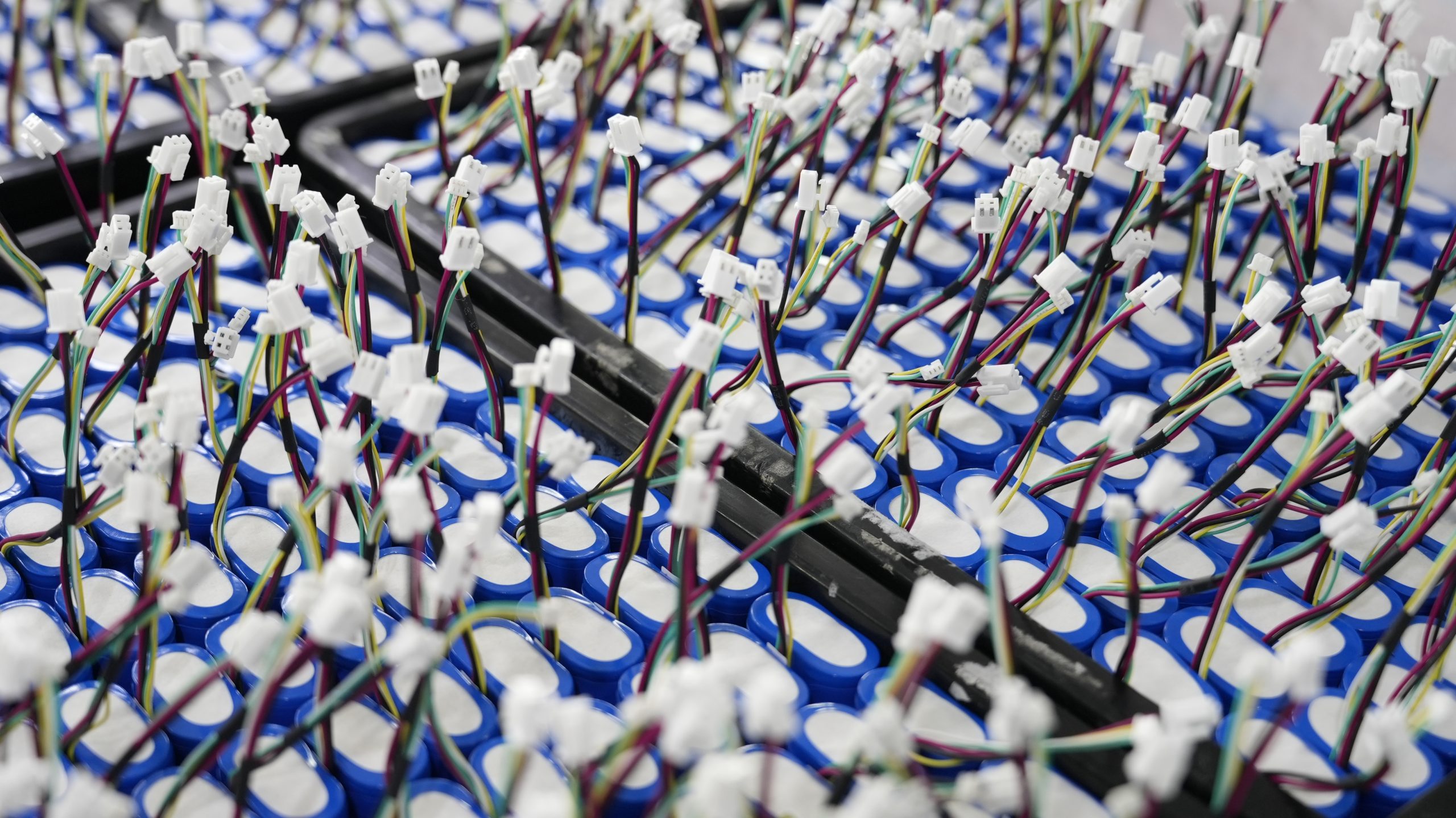

Portable medical devices rely on advanced lithium-ion battery packs to deliver consistent performance in critical environments. You must understand the risks associated with these batteries to meet safety and performance requirements and maintain regulatory compliance. Selecting the right battery and following safety testing protocols are essential for reducing patient risk and ensuring device reliability.

1.1 Device Malfunction

Device malfunction remains a leading concern in medical applications. You face significant challenges when batteries fail prematurely or deplete unexpectedly.

The rate of premature battery depletion in subcutaneous cardioverter-defibrillator (S-ICD) devices reaches 10.2% at 5 years and 23.7% at 6 years.

Within a median observation period of 65 months, the rate climbs to 29.1%.

These figures highlight the importance of rigorous testing and adherence to safety regulatory requirements.

Device malfunctions due to battery issues often result in unplanned clinic visits and the need for controller and battery changes. You may not encounter fatalities, but these incidents increase patient anxiety and healthcare costs. Technical problems with devices such as the HVAD® left ventricular assist device require unplanned visits and controller exchanges, exposing patients to risks during transitions without pump support.

A major concern arises when patients or caregivers disconnect power from rotary pumps during battery changes, which can cause immediate retrograde flow and threaten patient safety.

Improper battery selection for portable surgical devices, especially lithium-ion chemistries, introduces risks such as overheating, fire hazards, and difficulties in emergency battery removal. The U.S. FDA has documented numerous incidents of fires and explosions linked to lithium batteries in medical devices, emphasizing the need for strict compliance with safety and performance requirements.

Tip: Always verify battery certification and compatibility with your device to minimize patient risk and operational disruptions.

1.2 Thermal Runaway

Thermal runaway is a critical hazard in lithium-ion medical batteries. You must recognize the primary causes to implement effective safety features and meet safety regulatory requirements.

Overcharging generates excessive heat.

Internal short circuits result from unintended contact of components.

External heat sources push the battery beyond safe temperatures.

Physical damage from accidents compromises battery integrity.

Manufacturing defects introduce vulnerabilities.

Aging increases internal resistance, raising the risk of overheating.

Ultra-high-speed synchrotron X-ray imaging studies reveal that venting processes in lithium-ion cells can lead to cell rupture and explosion. Proper design and adherence to standards such as IEC 62133 are vital for mitigating these risks.

Common causes of fire hazards in portable surgical device batteries include:

Internal short circuits due to separator defects.

Overcharging from charger incompatibility or poor battery management systems (BMS).

Multiple overdischarges followed by charging below recommended voltage thresholds.

External short circuits and exposure to extreme temperature environments.

Year | Location | Reported Fires | Reported Injuries | Fatalities |

|---|---|---|---|---|

2023 | New York City | 268 | 150 | 18 |

The FDA has documented incidents of smoke production, overheating, and fires linked to batteries in mobile medical carts. These events can damage equipment and pose significant risks to patients and staff.

1.3 Security Issues

Security is a growing concern for battery-powered medical devices. You must address vulnerabilities to meet safety and performance requirements and maintain regulatory compliance.

Many medical devices cannot use traditional network defenses due to their discrete nature.

Increased security features require more power, which can reduce battery life and device functionality.

Compact device designs limit space for security hardware, resulting in weak encryption.

Devices are susceptible to radio signal interference, which attackers can exploit.

Increased power demands can lead to device malfunction if safety protocols are not followed.

Overheating of battery packs can result in thermal runaway and fire hazards.

Security features may drain battery life quickly, leading to device inoperability.

Medical devices often lack robust security protocols, making them targets for cyber attacks.

Wireless communication can be intercepted, leading to potential man-in-the-middle attacks.

Devices may be vulnerable to denial-of-service attacks due to reliance on wireless networks.

Data breaches in healthcare can compromise sensitive patient data. The average cost of a healthcare data breach is estimated at $7 million, including regulatory fines and legal fees. Operational disruptions, such as delays in accessing critical patient data due to ransomware attacks, can impact patient care.

“Information security risks resulting from certain threats and vulnerabilities could affect the safety and effectiveness of medical devices. These risks include unauthorized changes of device settings resulting from a lack of appropriate access controls.”

When selecting batteries for medical devices, you must consider application-specific risks across medical, robotics, security system, infrastructure, consumer electronics, and industrial sectors. The following table outlines key requirements and standards for battery selection:

Risk Type | Description |

|---|---|

Voltage Regulation Compatibility | Medical devices require precise voltage regulation to avoid malfunctions, especially in sensitive systems like medication delivery. Aging batteries can alter output voltage, leading to critical errors. |

Physical Form Factor Constraints | Batteries can swell during charging, necessitating careful design to prevent damage to devices. Custom shapes may be needed for space-constrained medical devices, balancing energy density and mechanical design. |

Smart Battery Communication | Advanced batteries need to communicate real-time status to devices. Variations in battery capacity due to temperature and age require dynamic calibration, complicating integration and accuracy over time. |

You must ensure that your battery selection meets all safety and performance requirements, certification standards, and regulatory compliance mandates. This approach reduces patient risk and supports the reliability of medical device battery systems.

Part2: Safety Testing Standards

Battery safety testing forms the backbone of regulatory compliance for medical device battery systems. You must understand the requirements and standards that govern the design, testing, and certification of batteries used in medical devices. These standards help you reduce patient risk, ensure safety and performance requirements, and support postmarket surveillance.

2.1 IEC 62133 Compliance

IEC 62133 stands as the primary international standard for rechargeable lithium-ion and nickel-based batteries in medical devices. You must follow this standard to achieve medical battery certification and meet safety regulatory requirements. IEC 62133 outlines a comprehensive set of requirements for safety and biocompatibility, focusing on both the battery cell and the complete battery pack.

Key requirements for IEC 62133 compliance include:

Cell selection: Choose high-quality cells from reputable suppliers to ensure consistent performance.

Battery management system (BMS) design: Integrate a robust BMS with redundant safety features to monitor voltage, current, and temperature.

Mechanical and enclosure design: Engineer the battery pack enclosure to withstand mechanical stress and protect internal components.

Thermal management: Design for effective heat dissipation during charging and discharging cycles.

Risk assessment documentation: Conduct a formal risk assessment to identify hazards and document mitigation strategies.

You must also perform a series of abuse tests to verify the safety features of your medical batteries:

Electrical abuse tests: Evaluate the battery’s response to electrical stress, such as overcharge and short circuit conditions.

Mechanical abuse tests: Assess the battery’s durability under mechanical shock, vibration, and impact.

Thermal abuse tests: Test the battery’s performance under extreme temperature conditions.

After completing these tests, you need to:

Obtain formal test reports from accredited laboratories.

Create and distribute the UN 38.3 test summary for transportation safety.

Prepare a declaration of conformity for regulatory submissions.

IEC 62133 also references other critical standards, such as IEC 60086-4 for primary lithium batteries and IEC 61960 for performance testing.

Note: Custom battery testing and thorough documentation are essential for successful certification and regulatory compliance.

2.2 FDA and ANSI/AAMI ES 60601-1

In the United States, you must comply with FDA regulations and ANSI/AAMI ES 60601-1 standards for medical electrical equipment. These requirements ensure that your medical device battery meets both safety and performance requirements and supports risk management throughout the product lifecycle.

The following table highlights the main differences between ANSI/AAMI ES 60601-1 and FDA regulations:

Aspect | ANSI/AAMI ES 60601-1 | FDA Regulations |

|---|---|---|

Scope | Comprehensive standards for medical electrical equipment | Regulates medical products including battery-powered devices |

Risk Management | Includes a risk management assessment model | Requires documentation of compliance with standards |

Production Requirements | Must be produced in UL-certified facilities | Recommendations for production, but less stringent |

Specific Standards | Requires compliance with IEC 60086-4 and IEC 62133 | Recognizes multiple IEC and UL standards |

Documentation | Extensive documentation requirements | Documentation required for compliance |

You must document your compliance with these standards and maintain records for postmarket surveillance. ANSI/AAMI ES 60601-1 requires a formal risk management assessment and extensive documentation, while the FDA focuses on ensuring that your devices meet recognized standards and safety and biocompatibility requirements.

Key Safety Testing Methods

You need to perform several critical tests to ensure the safety of your medical device battery:

Overcharge testing: Simulates excessive charging to identify risks of lithium plating, which can cause internal short circuits and thermal runaway.

Short circuit testing: Evaluates the battery’s response to accidental or intentional short circuits, which may lead to overheating or fire.

Thermal cycling and thermal abuse testing: Assesses battery performance and safety under repeated temperature fluctuations and extreme conditions.

Transportation safety testing (UN 38.3): Ensures batteries remain safe during shipping and handling.

The table below summarizes the most important standards and their focus areas:

Standard | Description |

|---|---|

IEC 62133 | Main international safety standard for rechargeable lithium and nickel batteries. |

UL 1642 & 2054 | Guidelines for lithium cell and battery pack safety. |

UN 38.3 | Safety testing requirements for batteries in transportation. |

IEC 60086-4 | Safety requirements for non-rechargeable lithium batteries. |

IEC 61960 | Performance standards for rechargeable lithium batteries. |

Overcharge, short circuit, and thermal cycling tests play a vital role in identifying battery safety issues. For example, overcharging a lithium-ion cell by just 50 mV can cause lithium plating and internal short circuits, leading to thermal runaway. These tests help you detect and mitigate risks before your devices reach the market.

Tip: Always verify that your medical device battery has passed all required safety testing and certification steps before deployment.

By following these standards and requirements, you ensure that your medical devices meet global safety and performance requirements, reduce patient risk, and support ongoing regulatory compliance.

Part3: Battery Safety and Risk Mitigation

3.1 Design Best Practices

You must prioritize robust design practices to meet safety and performance requirements for medical device battery systems. Industry research recommends several steps:

Establish realistic battery life specifications to avoid over-design and unnecessary costs.

Involve all functional groups early in the design process to gather comprehensive requirements.

Analyze and measure energy consumption to inform design decisions.

Address operational factors and potential risks upfront, including selecting the right lithium-ion chemistry and conducting reliability testing.

You should comply with standards such as IEC 62133 and ANSI/AAMI ES 60601-1 to achieve certification and regulatory compliance. Design devices to prevent the use of unapproved batteries and chargers, and provide clear instructions for safe usage. For implantable medical batteries, ensure long service life and reliable state-of-discharge indication. The development of secondary lithium-ion batteries allows for charging while implanted, improving usability and patient outcomes.

3.2 Hardware Protections

You need to integrate advanced hardware protections to enhance battery safety in medical devices. Common features include:

Overcharge protection

Thermal shutdown

Battery management systems

Battery health monitoring systems

The table below summarizes key safety features and their importance:

Safety Feature | Description | Importance in Medical Devices |

|---|---|---|

Protection Circuits | Prevent overcharging, over-discharging, short circuits | Ensure safe operation of critical devices |

Overheating Prevention | Minimize dangers of overheating and explosion | Maintain stable performance over long periods |

Reduced Risk of Failure | Continuous improvements lower device failure risk | Essential for life-supporting devices |

Hardware protection mechanisms, such as lifecycle management and fail-safe systems, are crucial for reducing battery-related incidents and ensuring regulatory compliance.

3.3 Maintenance and Monitoring

You must implement strict maintenance and monitoring protocols to maximize medical device battery reliability. Recommended practices include:

Conduct regular battery and power source checks.

Replace aging batteries promptly to prevent unexpected failures.

Schedule preventive maintenance to minimize device downtime.

Inspect cables, ports, and connectivity features regularly.

Use battery analyzers and impedance testers to assess battery health and performance.

Monitor battery run time and charge status, replacing batteries if run time drops below 80% of the original.

Semi-annual inspections and annual calibrations help maintain accuracy and reliability. Regular maintenance identifies issues early, preventing sulfation and corrosion, which prolongs battery life and reduces operational costs. Proactive risk management, including battery diagnostics and quality assurance, supports regulatory approvals and minimizes harm to patients and users.

You must collaborate with industry partners and maintain strict regulatory compliance to ensure battery safety in medical devices. Continuous monitoring and advanced risk mitigation strategies help you reduce failures. The table below compares lithium battery chemistries for medical and industrial applications:

Chemistry | Platform Voltage | Energy Density (Wh/kg) | Cycle Life |

|---|---|---|---|

LiFePO4 | 3.2 V | 90–160 | 2000+ |

NMC | 3.7 V | 150–220 | 1000–2000 |

FAQ

What makes Large Power lithium battery packs suitable for medical devices?

Large Power designs lithium battery packs with advanced BMS, robust safety features, and compliance with IEC 62133. You can request a custom battery consultation.

How do LiFePO4 and NMC chemistries compare for surgical device batteries?

Chemistry | Platform Voltage | Energy Density (Wh/kg) | Cycle Life |

|---|---|---|---|

3.2 V | 90–160 | 2000+ | |

NMC | 3.7 V | 150–220 | 1000–2000 |

LiFePO4 offers longer cycle life. NMC provides higher energy density.

How often should you test and replace lithium battery packs in critical medical applications?

You should test batteries semi-annually and replace them when capacity drops below 80%. Regular monitoring ensures safety and reliability in surgical environments.