Selecting a lithium battery for unmanned survey vessels requires you to focus on energy capacity, durability, safety, and supplier quality. You must evaluate lithium battery for unmanned survey vessels against marine standards, as lithium marine batteries face unique risks:

Since 2012, at least 12 reported failures of lithium batteries for marine use have occurred, often due to water ingress and coolant leaks.

Failures can result in fire or explosion, making safety features essential.

High energy density lithium battery for unmanned survey vessels supports advanced propulsion and reliable operations. You improve performance and reduce risk when you choose the right lithium battery and partner with trusted suppliers. You must choose the right lithium battery to meet demanding marine environments.

Key Takeaways

Choose lithium batteries that match your vessel’s voltage and energy needs, considering mission duration, equipment load, and environmental factors for reliable performance.

Prioritize safety by selecting batteries with strong management systems, certified chemistries like LiFePO4, and compliance with marine safety standards to prevent failures and hazards.

Work with trusted suppliers who offer quality certifications, good customer support, and warranties to ensure long-lasting, efficient, and safe battery operation.

Part1: Power Needs

1.1 Capacity and Voltage

You must begin your battery selection process by calculating the energy requirements for your unmanned survey vessel. The total capacity you need depends on mission duration, equipment load, and environmental factors. Follow these steps to estimate the required battery capacity:

Predict the total energy consumption for the mission, including motors, sensors, and any photovoltaic panels.

Use a smart energy management system (SEMS) that applies algorithms like A*Pb to optimize your vessel’s path and speed, accounting for changing sea currents and waves.

Add a safety margin—typically 20%—to ensure you have enough energy at the end of the mission.

Monitor motor voltage/current, battery status, and environmental data in real time to adjust speed and optimize energy use.

Factor in energy contributions from photovoltaic panels, which can increase available battery capacity by up to 21% in some missions.

Divide the mission into steps: mesh the area, optimize the path at constant speed, then optimize speed for the chosen path.

Validate your calculations with experimental data; studies show less than 1.5% deviation between predicted and actual energy consumption.

Adjust speed during the mission based on remaining battery energy and predicted PV contributions to maintain the safety margin.

Tip: Always size your battery capacity not just for mission duration and equipment load, but also for environmental conditions and energy harvesting capabilities. This ensures reliable performance and maximizes efficiency.

When selecting lithium battery cells, you must match the voltage to your vessel’s system requirements. The table below summarizes typical voltage and capacity ranges for marine survey applications:

Use Case | Typical Voltage | Capacity Range | Application Notes |

|---|---|---|---|

Small fishing boats | 12V | ~60Ah LiFePO₄ | Powers sonar and small motors for several hours |

Mid-size cruisers | 24V | ~100Ah bank | Supports multiple loads like fridge, navigation, lights |

Liveaboard / extended use | 24V or higher | 2× 100–200Ah | Hybrid charging setups with engine, solar, shore power |

Native voltage lithium battery cells (such as single 24V or 36V units) simplify wiring and improve battery management system performance. Product lines cover voltages from 12V up to 72V, supporting a wide range of marine survey and industrial applications. If you need a custom battery solution, click here for consultation.

1.2 Discharge Rate

The discharge rate determines how quickly your lithium battery cells can deliver energy to your vessel’s equipment. You must ensure the continuous discharge rate exceeds the maximum amp draw of your motors and electronics. The table below shows industry standards for discharge rates in marine lithium battery packs:

Parameter | Recommended Rate | Maximum Rate |

|---|---|---|

Discharge Rate (LiFePO4) | 0.5C (50% of capacity) | 1C (100% of capacity) |

Exceeding a 1C discharge rate can cause overheating, damage, and reduce battery lifespan. Staying within these rates ensures safety, performance, and longevity. The C-rate expresses the discharge current relative to the battery’s capacity. For example, a 1C rate means the battery can discharge its full capacity in one hour. High energy density lithium battery cells support higher discharge rates, but you must balance energy density with safety and cycle life.

The continuous discharge rate must exceed the maximum amp draw of your equipment.

This ensures proper performance and prevents battery overload.

The continuous discharge rate is a critical measurement for safe and effective marine battery use.

Note: Always verify the discharge rate of your lithium battery cells against your vessel’s peak energy requirements. This protects your system and ensures reliable performance.

1.3 Battery Management System

A robust Battery Management System (BMS) is essential for marine lithium battery packs. The BMS monitors and controls lithium battery cells to ensure safe operation and maximize performance. Key functions include:

Protection from under-voltage and over-voltage to prevent cell damage.

Temperature monitoring and control to avoid thermal runaway and fires.

Protection from internal and external short circuits.

Cell balancing to maintain uniform charge and discharge across cells.

Automatic shutdown in unsafe conditions to protect both battery and user.

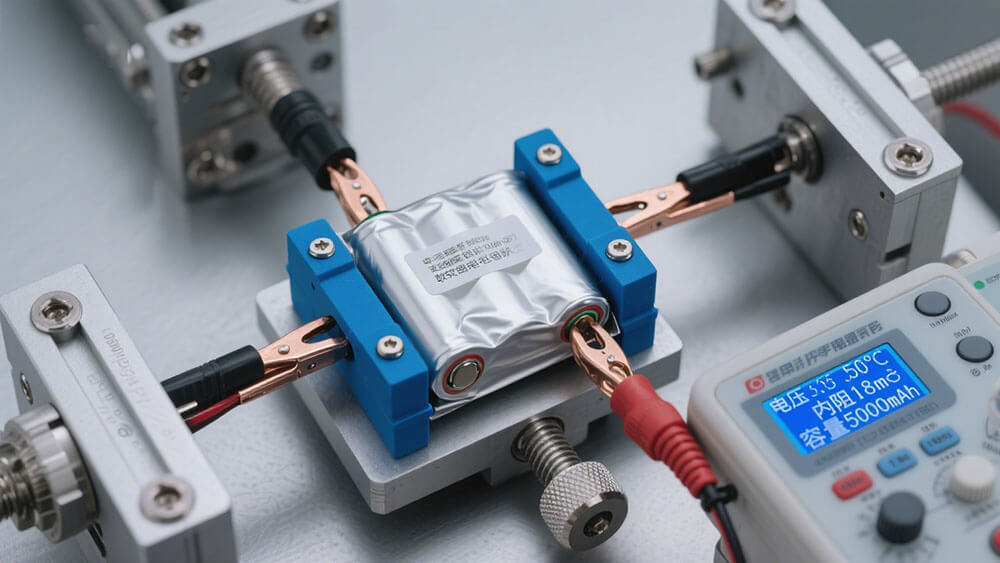

The BMS continuously measures voltage, current, and temperature, estimating remaining charge, capacity, and health status. It adjusts charging power and controls energy output to prevent overcharging and deep discharging. Fault diagnosis and protection features detect issues such as over-voltage, under-voltage, over-current, over-temperature, short circuits, and insulation faults, providing timely warnings and interventions.

Advanced BMS technology uses AI-driven algorithms for real-time monitoring and predictive maintenance, enhancing safety and longevity under extreme conditions. These systems include military-grade encryption for data security and integrate with vessel management systems. Some BMS designs employ individual microchips on each lithium battery cell for granular monitoring and wireless communication, improving fault tolerance and reducing wiring complexity. Predictive analytics optimize battery performance in harsh environments, supporting reliable performance for unmanned survey vessels.

For more details on BMS technology and its applications in medical, robotics, security, infrastructure, consumer electronics, and industrial sectors, visit our BMS blog.

A high energy density lithium battery pack with advanced BMS ensures your vessel operates safely and efficiently, even in challenging marine environments. Fast charging capabilities and smart energy management further enhance operational flexibility.

Part2: Chemistry and Safety

2.1 LiFePO4 Marine Lithium Battery

When you select a marine lithium battery for unmanned survey vessels, you must understand the differences between lithium battery chemistries. The most common types include LiFePO4, NMC, LCO, LMO, and LTO. Each chemistry offers unique advantages and trade-offs for marine applications.

The table below compares key properties of these chemistries:

Chemistry | Platform Voltage | Energy Density (Wh/kg) | Typical Cycle Life | Marine Suitability |

|---|---|---|---|---|

LiFePO4 | 3.2V | 90–140 | 2,000–5,000 | Excellent (high safety, long life) |

NMC | 3.6V | 150–220 | 1,000–2,000 | Good (higher density, moderate life) |

LCO | 3.7V | 150–200 | 500–1,000 | Limited (lower cycle life) |

LMO | 3.7V | 100–150 | 700–1,500 | Moderate (good power, less life) |

LTO | 2.4V | 70–80 | 5,000–10,000 | Niche (ultra-long life, low density) |

You will find that LiFePO4 marine lithium batteries stand out for several reasons:

They deliver a longer lifespan, often reaching 2,000 to 5,000 cycles, which far exceeds most other lithium chemistries.

They provide excellent thermal stability and safety, reducing risks of fire or thermal runaway.

LiFePO4 batteries use non-toxic materials, making them more environmentally friendly than cobalt-based chemistries.

They maintain stable voltage and high charge/discharge efficiency, which is critical for consistent marine power delivery.

Their robust design supports high discharge currents, ideal for powering demanding marine electronics.

Although LiFePO4 batteries have slightly lower energy density than NMC or LCO, their reliability and safety features make them the preferred choice for lithium batteries for marine use. You benefit from a marine lithium battery that resists degradation from heat, vibration, and moisture, ensuring dependable operation in harsh environments.

Tip: For most unmanned survey vessels, LiFePO4 marine lithium batteries offer the best balance of safety, performance, and longer lifespan.

2.2 Cycle Life and Temperature Range

You must consider both cycle life and temperature range when choosing lithium marine batteries. Cycle life measures how many full charge and discharge cycles a battery can complete before its capacity drops below 80% of its original value. The table below highlights the difference between LiFePO4 and other lithium-ion batteries:

Battery Chemistry | Typical Cycle Life | Marine Environment Suitability |

|---|---|---|

LiFePO4 | 2,000 to 5,000 cycles | Preferred for marine/RV systems due to stability and deep-cycle reliability |

Other Lithium-Ion | 500 to 1,500 cycles | Less preferred; lower cycle life and durability |

With a longer lifespan, LiFePO4 marine lithium batteries reduce replacement frequency and lower total cost of ownership. This advantage is critical for unmanned survey vessels that operate in remote or challenging locations.

Temperature range also affects the performance and safety of lithium batteries for marine use. The recommended operating temperature for marine lithium battery packs is 15°C to 35°C (59°F to 95°F). Operating outside this range can reduce capacity, increase internal resistance, and accelerate aging. Charging or discharging below 0°C (32°F) risks lithium plating and capacity loss, while temperatures above 45°C (113°F) can cause rapid degradation and safety hazards. You should ensure proper ventilation and select batteries designed for high-temperature resistance to maintain optimal performance and safety.

Note: Always monitor battery temperature and avoid extreme conditions to maximize the longer lifespan and reliability of your lithium marine batteries.

2.3 Safety Features

Safety is the top priority when you deploy lithium batteries for marine use. Modern marine lithium battery packs include advanced safety features to protect your vessel, crew, and equipment.

Key safety features include:

Overcharge protection using smart chargers and integrated battery management systems (BMS) that automatically stop charging when full.

Thermal runaway prevention through early warning systems, thermal management, and robust cell design.

Short circuit protection by enclosing each battery in inner packaging and using strong outer packaging to prevent movement and impact.

Built-in BMS that monitors voltage, current, and temperature, providing real-time diagnostics and automatic shutdown in unsafe conditions.

Compliance with international safety standards, such as the UN Manual of Tests and Criteria Section 38.3, which ensures batteries meet strict design and transport requirements.

You must also follow maritime regulations, including the International Maritime Dangerous Goods (IMDG) Code. These rules require proper packaging, labeling, and documentation for lithium batteries for marine use. For example, the state of charge must not exceed 30% for independent shipments, and packages must display Class 9 hazard labels. Manufacturers must provide test summary documents to confirm compliance with safety standards.

While current overcharge protection and thermal runaway prevention technologies have greatly improved safety, you must maintain and monitor these systems to ensure full effectiveness. No technology can eliminate all risks, so you should implement multi-level safety strategies and ongoing maintenance.

⚠️ Alert: Never overlook safety features or regulatory compliance when selecting lithium marine batteries. Proper implementation protects your investment and ensures safe operation in all marine environments.

Part3: Quality and Fit

3.1 Size and Weight

You must select lithium battery packs that fit the physical constraints of your unmanned survey vessel. Standard marine lithium batteries, such as those used in BlueBoat USV and BlueROV2, feature compact dimensions and manageable weight. The table below shows typical specifications:

Parameter | Specification |

|---|---|

Nominal Voltage | 14.8 V |

Nominal Capacity | 18.0 Ah |

Cell Configuration | 4S6P |

Diameter | Approximately 74.2 mm |

Length | Approximately 146 mm |

Weight | About 1152 grams (2.54 lbs) |

Battery weight and volume directly affect vessel stability and operational efficiency. You must balance energy capacity with payload limits. Efficient energy management and auxiliary sources, such as photovoltaic panels, can extend mission range and reduce energy consumption. Optimized energy management systems help you overcome limitations imposed by battery size and weight, improving overall performance.

Tip: Always verify that your lithium battery pack fits securely inside watertight enclosures and does not exceed the vessel’s payload rating. Proper fit ensures safety and reliable operation.

3.2 Supplier Quality and Certifications

You should prioritize supplier quality when sourcing lithium battery packs for unmanned survey vessels. Suppliers with strong brand reputation, proven manufacturing infrastructure, and robust customer support deliver higher reliability and satisfaction. Look for suppliers who provide comprehensive certifications, such as UN38.3, UL 1973, CE Marking, IEC 62133, ISO 9001, RoHS, and DOT regulations. The table below summarizes key certifications:

Certification | Purpose | Importance for Marine Lithium Battery Suppliers | Region/Market |

|---|---|---|---|

UN38.3 | Safe transportation | Critical for shipping compliance | Global |

UL 1973 | Safety standard | Safety assurance in marine environments | North America |

CE Marking | Health, safety, environment | Regulatory compliance | Europe |

IEC 62133 | Rechargeable battery safety | Environmental compliance | Global |

ISO 9001 | Quality management | Consistent product quality | Global |

RoHS | Hazardous substances | Environmental sustainability | Europe |

DOT Regulations | Transport safety | US compliance | United States |

High supplier quality ratings correlate with battery reliability and customer satisfaction. Suppliers with industry experience, advanced manufacturing, and strict quality control provide durable lithium battery packs with long lifespan and superior performance. You benefit from strong warranties, technical support, and global service networks, which ensure ongoing customer support and quick issue resolution.

Note: Choose suppliers with transparent test reports, certifications, and a history of positive reviews. Reliable customer support and after-sales service are essential for B2B clients managing fleets of unmanned survey vessels.

Total Cost of Ownership

You must consider total cost of ownership when evaluating lithium battery packs. Although initial costs for marine lithium batteries are higher than lead-acid alternatives, you save money over time due to longer lifespan, minimal maintenance, and fewer replacements. For example, a 12V 100Ah LiFePO4 battery costs about $1,131 to $1,925 over ten years, including installation, maintenance, and charging. Lead-acid batteries require multiple replacements, raising costs to $3,120–$4,445. Longer battery lifespan reduces operational interruptions and maintenance labor, improving overall efficiency for your fleet.

To maximize battery lifespan, follow recommended maintenance practices:

Use compatible marine chargers with smart charging technology.

Charge to 80–90% for most uses.

Avoid charging in extreme temperatures.

Inspect batteries regularly for performance changes.

Clean and protect connections monthly.

Ensure good airflow and control humidity.

Insulate compartments and monitor temperature.

⚡️ Strong customer support and clear warranty terms—such as 10-year coverage—further reduce risk and ensure reliable performance for B2B operations.

To choose the best battery for marine use, you should:

Match the lithium battery for unmanned survey vessels to your vessel’s voltage and capacity needs.

Prioritize safety with certified marine batteries and robust containment.

Select reliable suppliers with strong support.

Common Mistake | Impact |

|---|---|

Ignoring chemistry trade-offs | Reduced safety, shorter life |

Overlooking compatibility | System failures |

FAQ

1. What makes Large Power lithium battery packs suitable for unmanned survey vessels?

Large Power designs lithium battery packs for marine use with advanced BMS, robust safety features, and industry certifications. You can click here for custom consultation.

2. How does LiFePO4 compare to other lithium chemistries for marine applications?

Chemistry | Voltage | Energy Density (Wh/kg) | Cycle Life |

|---|---|---|---|

LiFePO4 | 3.2V | 90–140 | 2,000–5,000 |

NMC | 3.6V | 150–220 | 1,000–2,000 |

LCO | 3.7V | 150–200 | 500–1,000 |

LiFePO4 offers longer cycle life and higher safety for marine environments.

3. Can you get custom lithium battery solutions for industrial fleets?

Yes. You can request custom lithium battery packs for industrial fleets. Click here for custom consultation to discuss your project with Large Power’s engineering team.