Setting battery performance standards defines the required metrics and testing for lithium battery packs, ensuring your products meet strict safety, reliability, and regulatory demands. Testing, certification, and regulatory bodies drive these standards. The table below shows recent lithium battery recalls, highlighting the crucial role of standards for safety and compliance.

Year | Product | Hazard | Recall Purpose/Details |

|---|---|---|---|

2020 | Lithium-ion battery packs | Fire and explosion | Recalls issued to mitigate fire and explosion risks |

2019 | Lithium-ion battery-powered hoverboards | Fire and burn risks | Recalls issued to prevent burn injuries |

2018 | Lithium-ion battery-powered laptops | Fire and burn risks | Recalls issued to address fire and burn hazards |

Key Takeaways

Clear battery performance standards help you choose safe, reliable lithium battery packs that meet your needs and regulations.

Testing and certification ensure batteries perform well under real conditions and reduce risks like fires or failures.

Following global and regional standards and obtaining certifications builds trust, avoids recalls, and opens new market opportunities.

Part 1: Battery Performance Standards

1.1 Key Metrics and Parameters

When you evaluate lithium battery packs for industrial, transportation, or infrastructure applications, you rely on clear performance standards. These standards define the metrics that determine if a battery meets your operational needs and regulatory requirements. The most critical parameters include:

Specific capacity (Ah): Measures how much charge a battery can store.

Energy (Wh): Indicates the total energy output available for your application.

Cycle life: Shows how many charge-discharge cycles the battery can complete before its capacity drops below a set threshold.

Voltage window: Defines the safe operating voltage range for the battery.

Coulombic efficiency (CE): Reflects the ratio of charge output to input, which impacts long-term reliability.

Thermal stability: Assesses how well the battery resists overheating during operation or environmental tests.

Environmental conditions: Includes temperature, humidity, and vibration resistance, which are vital for transportation and industrial use.

Material recyclability and scale cost: Important for sustainability and cost management.

Tip: For lithium battery packs, you should also consider electrode fabrication parameters, such as the ratios of active material, conductive additives, and binder, as well as areal mass loading. These factors influence both performance and safety.

The following table summarizes the main metrics and their measurement units, supporting your selection and evaluation process:

Metric / Variable | Description | Unit |

|---|---|---|

Capacity | Energy capacity at various cycle numbers and SOH | Ampere-hours (Ah) |

Energy | Accumulative energy measured during tests | Watt-hours (Wh) |

Cycle number | Number of ageing cycles tested | Count |

State of Health (SOH) | Battery health as a percentage | Percentage (%) |

Cell voltage | Voltage during test | Volts (V) |

Applied current | Charge/discharge current | Amperes (A) |

Accumulative ampere-hours | Total charge passed through the cell | Ampere-hours (Ah) |

Accumulative watt-hours | Total energy passed through the cell | Watt-hours (Wh) |

Temperature | Ambient temperature during testing | Degrees Celsius (°C) |

You can use these metrics to benchmark lithium battery packs for industrial, medical, robotics, security, and consumer electronics applications. For more details on sustainable battery design, visit our approach to sustainability.

1.2 Battery Testing Standards

Battery testing standards ensure that every lithium battery pack you deploy meets strict requirements for safety, durability, and performance. These standards guide the testing process, from initial design to final product validation. You will encounter several types of battery testing, including:

Capacity and energy tests: Verify that the battery delivers the expected charge and energy output.

Cycle life tests: Assess how the battery performs over repeated charge-discharge cycles.

Environmental tests: Simulate real-world conditions such as extreme temperatures, humidity, and vibration.

Thermal stability and abuse tests: Evaluate the battery’s resistance to overheating, short-circuiting, and mechanical stress.

Transportation safety tests: Confirm that the battery can withstand shocks, drops, and other hazards during shipping.

Industry standards such as ISO, IEC, and SAE provide detailed protocols for these tests. For example, the Technical Manual BCIS-03A outlines procedures for testing physical and chemical characteristics of battery components. Comparative studies show that ISO standards emphasize global safety and interoperability, while SAE standards focus on rigorous engineering tests for industry needs. Many manufacturers comply with both to ensure reliability and market acceptance.

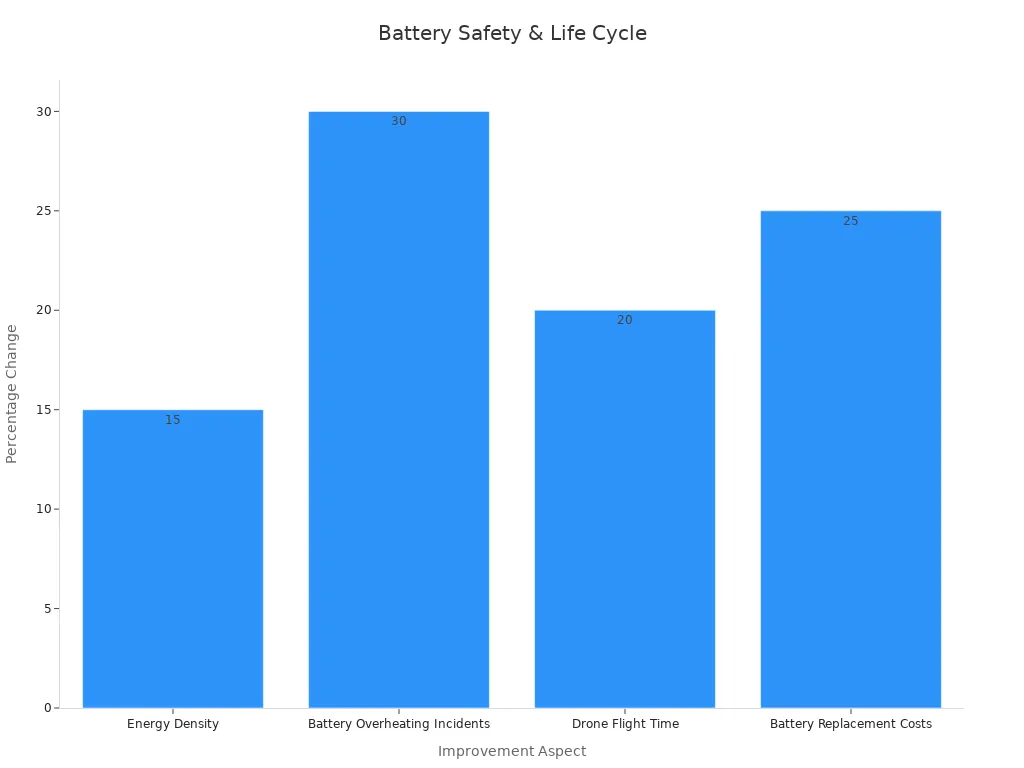

A case study from an energy storage company demonstrated that automated lithium battery testers improved testing consistency and reduced errors by 30%. Automated systems also provide detailed reporting, which helps you maintain reliable battery testing across different manufacturers.

Note: Enhanced test methodologies, such as those integrating IEC 62660-1 and ISO/DIS 12405-1, allow you to compare lithium battery cells from various suppliers. These methods reveal differences in cell behavior and help you select the optimal battery for your application.

The chart above illustrates how adherence to battery testing standards leads to measurable improvements in energy density, reduction in overheating incidents, longer drone flight times, and lower replacement costs.

1.3 Why Standards Matter

You depend on battery performance standards to ensure safety, reliability, and consistent quality in your operations. Strict adherence to these standards reduces the risk of catastrophic failures, such as thermal runaway events, which can cause fires or explosions. Regulatory frameworks like DO-311A require mandatory protections, including charge/discharge limits and thermal runaway containment, to guarantee operational safety.

Empirical studies show that early fault detection and real-time diagnostics, enabled by AI-enhanced cloud-based frameworks, significantly improve battery safety diagnostics and extend battery life. These tools help you detect defective cells and support safety assessments throughout the battery lifecycle, even in challenging industrial environments.

Callout: Real-time monitoring systems and defined battery safety standards have proven to reduce maintenance costs, enhance anomaly detection, and improve decision-making in industrial battery management. Case studies highlight benefits such as reduced downtime and improved operational efficiency.

Industry reports provide statistical comparisons of safety incidents before and after implementing safety standards. For example, safety training programs, audits, and risk assessments have led to measurable reductions in total recordable accident rates (TRAR) and improved safety readiness (SR) across sectors like transportation and industrial infrastructure.

Safety incident reports document that lithium battery safety issues often stem from thermal runaway, overcharge, or degradation. Reliable state-of-health metrics and predictive maintenance systems, supported by robust standards, help you prevent these risks.

Degradation studies reveal that capacity loss, resistance increase, and lithium plating not only reduce performance but also elevate safety risks, making continuous monitoring and compliance with battery safety standards essential.

If you want to ensure your lithium battery packs meet the highest safety and performance standards for your industrial, medical, robotics, security, or infrastructure projects, consider customized consulting from Large Power.

Part 2: Setting and Certifying Standards

2.1 Setting Battery Performance Standards

When you work with lithium battery packs, setting battery performance standards becomes a collaborative process. Industry experts, regulatory agencies, and independent testing institutions join forces to define these standards. You see this process in action as technical committees review new research, analyze field data, and consult with manufacturers. They focus on real-world needs, such as safety, reliability, and environmental impact.

You must consider both global and regional regulations. For example, european battery regulations set strict requirements for environmental safety and recycling. In North America, us battery manufacturing regulations and canadian battery manufacturing regulations address local safety and transportation needs. These regulations shape the standards that guide your product development and market entry.

The process of setting battery performance standards involves several key steps:

Identifying industry needs: Committees gather feedback from manufacturers, users, and researchers.

Drafting technical requirements: Experts define measurable criteria for safety, cycle life, and energy density.

Public review and revision: Stakeholders review drafts and suggest improvements.

Final approval and publication: Regulatory bodies publish the standards, making them mandatory for compliance.

You benefit from this process because it ensures that every lithium battery pack meets consistent benchmarks for safety and performance. These standards also support regulatory compliance and help you avoid costly recalls or market restrictions.

Tip: Stay updated on changes in european battery regulations and us battery manufacturing regulations. These updates can affect your product design, testing, and certification process.

2.2 Regulatory Bodies and Organizations

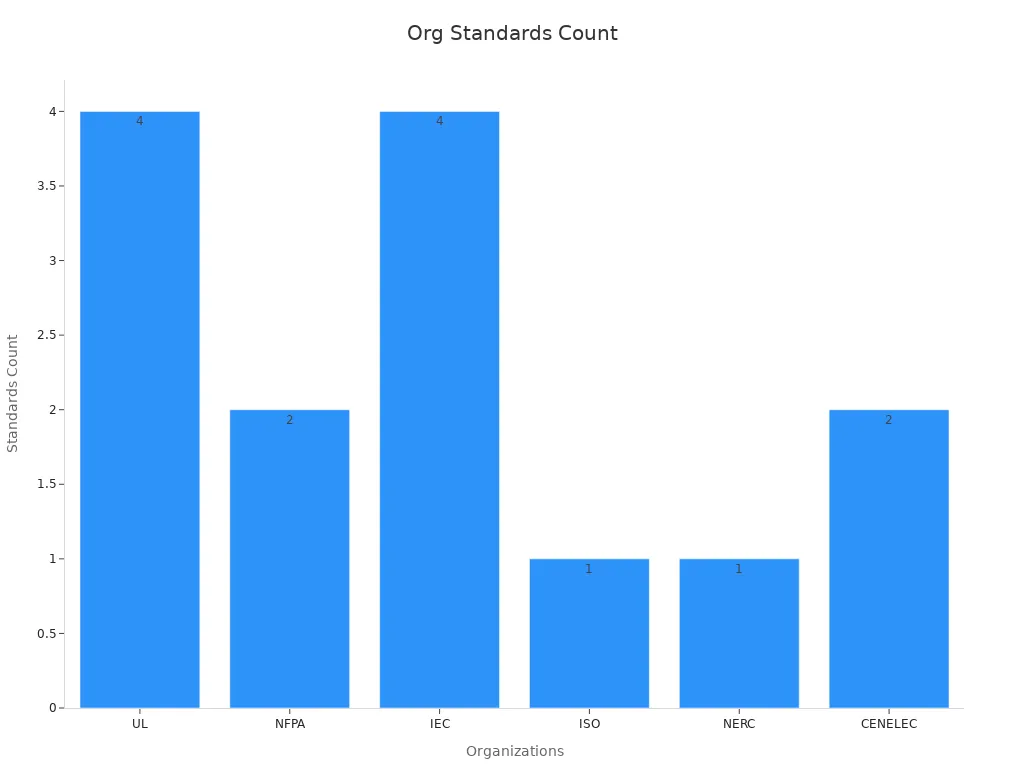

You rely on several key organizations to set and enforce standards for lithium battery packs. These bodies publish detailed requirements that cover everything from cell chemistry to system integration. The most influential organizations include:

Organization / Regulatory Body | Role / Contribution | Relevant Standards / Notes |

|---|---|---|

Underwriters Laboratories (UL) | Certification and safety testing body; develops standards and participates in standards panels worldwide | UL 1973, UL 9540, UL 9540A, UL 1741 |

National Fire Protection Association (NFPA) | Governs fire safety and installation codes in the U.S. | NFPA 855, NFPA 70 |

International Electrotechnical Commission (IEC) | Publishes international standards for electrical and battery safety | IEC 62619, IEC 62933, IEC 62109, IEC 61400-21 |

International Standards Organization (ISO) | Develops international standards including energy management | ISO 50001 |

North American Electric Reliability Corporation (NERC) | Sets reliability standards for bulk power systems including battery storage | NERC Standards |

European Committee for Electrotechnical Standardization (CENELEC) | Develops European standards for electrical installations and renewable energy integration | CENELEC Standards, EN 50549 |

You see these organizations play a central role in shaping the global landscape for battery safety and performance. For example, the IEC standard IEC 62619 sets requirements for the safe operation of lithium battery packs in industrial and stationary applications. UL standards, such as UL 1973 and UL 9540, focus on safety certifications for stationary energy storage and transportation systems.

The chart below shows the number of standards published by each organization, highlighting their influence in the industry:

You must also pay attention to regional regulations. European battery regulations and CENELEC standards ensure that your products meet strict environmental and safety requirements in the European market. In North America, us battery manufacturing regulations and canadian battery manufacturing regulations address local needs for fire safety, grid reliability, and transportation.

Note: Following the latest IEC standard and UL requirements helps you achieve global market access and reduces the risk of non-compliance penalties.

2.3 Battery Pack Certifications

You need battery pack certifications to prove that your products meet all relevant standards and regulations. The certification process involves a series of measurable steps, each designed to verify safety, performance, and regulatory compliance.

Key steps in the certification process:

Initial assessment: Inspect the battery pack for visual damage and verify basic functionality.

Testing and evaluation: Conduct charge/discharge tests, cycle life analysis, and state-of-health (SoH) measurements. Use metrics like internal resistance, capacity retention, and thermal stability.

Safety and compliance checks: Perform abuse tests, transportation safety evaluations, and environmental simulations.

Documentation and traceability: Maintain detailed records of test results, materials, and manufacturing processes.

Certification issuance: Submit all documentation to an accredited body, such as UL or IEC, for final review and approval.

You must follow ISO/IEC 17020 and ISO/IEC 17065 standards during this process. These standards require impartiality, competence, transparency, and traceability from certification bodies. Adhering to these requirements ensures that your battery pack certifications are reliable and recognized worldwide.

Benchmarks for certification include:

Internal resistance and capacity retention

Cycle life and efficiency

Frequency of high temperature events

Compliance with IEC 62619 for first-life battery safety and UL 1974 for repurposed battery safety

You also benefit from accessible battery management system (BMS) data, which streamlines the certification process and reduces testing costs. The framework for battery pack certifications continues to evolve, aligning second-life battery standards with first-life requirements to ensure consistent safety and performance.

Certification Standard | Statistical Improvement / Market Acceptance Benefit | Description |

|---|---|---|

ISO 45001 | 22.6% decrease in workplace accident rates | Adoption leads to significant reduction in occupational health and safety incidents, demonstrating operational compliance improvement. |

ISO 9001 | 15% increase in business opportunities within 1 year | Certification correlates with enhanced company performance and market opportunities. |

Automotive Sector (ISO standards) | 1.3% to 1.8% gross profit contribution | |

ISO 13485 | Over 33,000 organizations certified worldwide | Reflects critical role in market access and patient safety, indicating broad market acceptance. |

You gain several advantages from battery pack certifications:

You ensure compliance with federal regulations and avoid costly fines.

You unlock new market opportunities, including eligibility for government contracts and incentive programs.

You improve your reputation and competitiveness in the global battery market.

Callout: Rigorous safety certifications and adherence to international standards help you mitigate risks, enhance product quality, and achieve faster market acceptance. For custom consulting on battery pack certifications and regulatory compliance, visit Large Power.

You gain measurable improvements in product safety and market access by following established standards and adapting to evolving regulations. Recent analyses confirm that optimized lithium battery design and recycling efficiency depend on compliance. To stay ahead, you should track regulatory deadlines, use digital tools, and regularly review industry best practices.

FAQ

1. What is the typical certification process for lithium battery packs?

You submit your lithium battery pack for third-party testing. The process includes safety, performance, and environmental tests. Certification bodies like UL or IEC issue compliance certificates.

2. How do battery performance standards impact your business operations?

You reduce safety risks, improve product reliability, and gain faster market access. Meeting standards also helps you avoid costly recalls and regulatory penalties.

3. Where can you get expert consulting for custom lithium battery solutions?

You can contact Large Power for tailored consulting on lithium battery pack design, certification, and compliance for industrial and commercial applications.