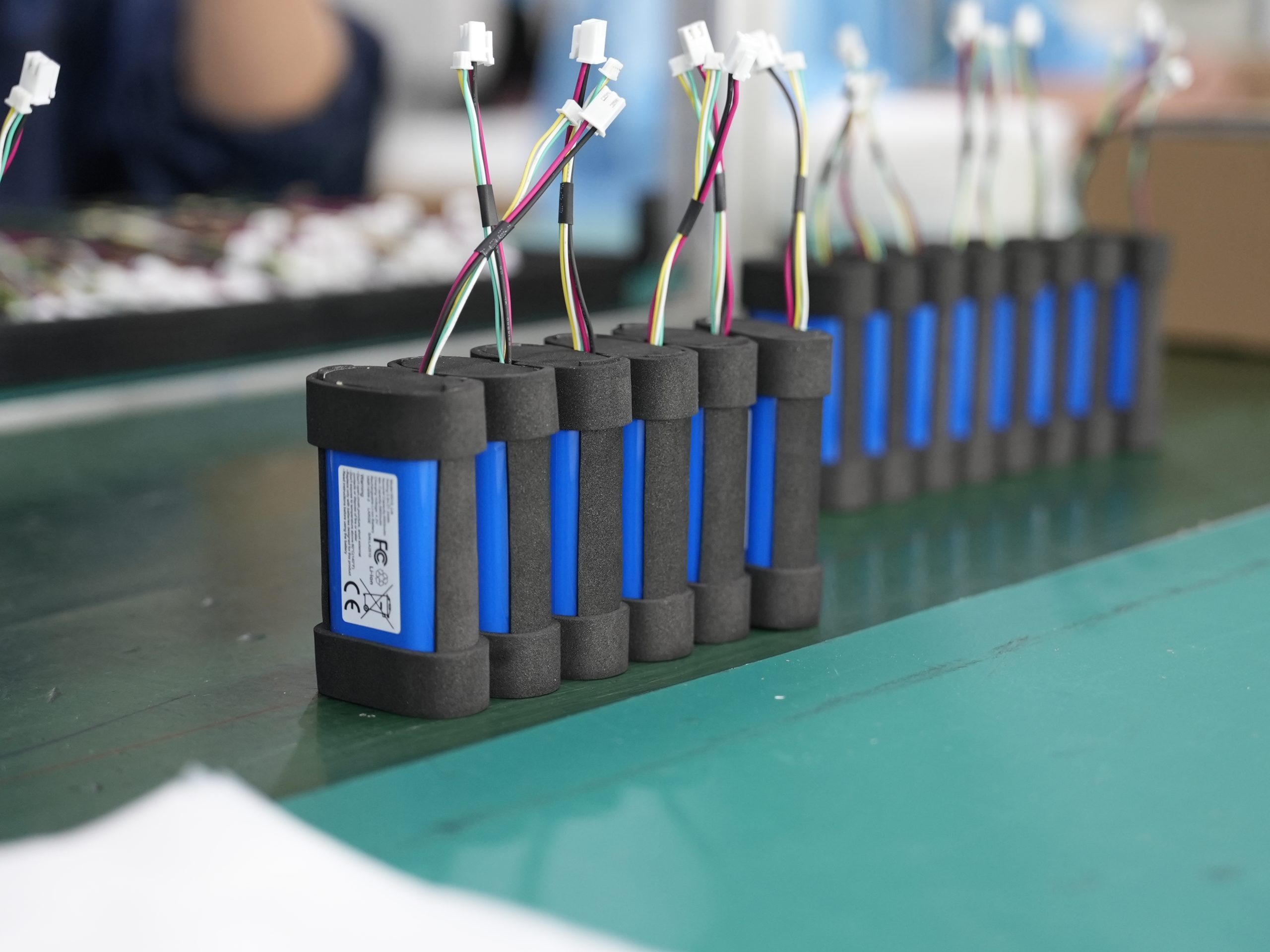

You rely on smart batteries and advanced data communication to keep medical devices safe and reliable. Real-time monitoring delivers instant diagnostics, crucial in emergencies. BLE technology provides seamless connectivity and low power consumption, boosting operational efficiency.

Enhanced Patient Care: Access to real-time data improves decision-making in emergencies.

Improved Documentation Accuracy: Reduces errors in patient records, crucial in high-pressure situations.

Challenge | Description |

|---|---|

Energy density limitations | Restricts advanced device features. |

Temperature sensitivity | Threatens safety and reliability. |

Cycle life degradation | Increases replacement costs. |

Inadequate safety mechanisms | Risks device failure. |

Regulatory compliance complexities | Limits design options. |

Key Takeaways

Smart batteries provide real-time monitoring, ensuring medical devices remain operational and safe during emergencies.

Advanced battery management systems (BMS) enhance safety by tracking battery health and preventing failures, reducing downtime.

Data communication protocols enable seamless connectivity, allowing for remote monitoring and timely interventions in patient care.

Part1: Smart Batteries in Medical Devices

1.1 Real-Time Monitoring and Diagnostics

You depend on smart batteries to deliver real-time monitoring and diagnostics in medical devices. These advanced battery systems use embedded sensors and microcontrollers to track voltage, temperature, and charge cycles. With smart battery monitoring, you receive instant alerts about battery health, which helps you prevent unexpected failures during critical procedures.

Tip: Real-time data from smart batteries allows you to schedule maintenance before issues arise, reducing the risk of device downtime in emergency rooms or intensive care units.

Smart batteries, especially lithium-ion and lithium-polymer/LiPo packs, offer high energy density and stable performance. You can see the difference in the following table, which compares common lithium battery chemistries used in medical applications:

Chemistry | Nominal Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) | Typical Medical Use Cases |

|---|---|---|---|---|

3.2 | 100–180 | 2,000–5,000 | Portable monitors, infusion pumps | |

NMC | 3.7 | 160–270 | 1,000–2,000 | Defibrillators, ventilators |

LCO | 3.7 | 180–230 | 500–1,000 | Diagnostic imaging devices |

LMO | 3.7 | 120–170 | 300–700 | Portable ECGs |

LTO | 2.4 | 60–90 | 10,000–20,000 | Backup power for critical systems |

3.7 | 300–500 | / | Next-gen implantable devices |

Smart battery monitoring ensures you always know the exact state of charge and health status. For example, a defibrillator powered by an unchecked, five-year-old battery failed during a resuscitation attempt. This incident highlights the necessity of continuous monitoring to guarantee device reliability in emergencies.

1.2 Enhancing Safety and Reliability

You enhance safety and reliability in medical devices by using smart batteries with advanced battery design. These batteries feature built-in protection circuits that guard against overcharging, overheating, and deep discharge. Smart battery management systems (BMS) further improve safety by collecting and analyzing data in real time.

The following table summarizes how smart batteries improve safety and reliability in your operations:

Benefit | Description |

|---|---|

Reduced Downtime | Systems stay online longer, even during emergencies. |

Improved Device Safety | Avoiding overheating and chemical breakdowns reduces risk. |

Extended Battery Lifespan | Preventing overcharge and thermal damage increases battery cycles. |

You also benefit from compliance with international safety standards. For example:

Standard | Description |

|---|---|

UL 2054 | Recognized by the FDA for medical devices with lithium batteries, focusing on safety and performance. |

IEC 62133 | International standard for safe operation of portable sealed lithium-ion cells and batteries in various applications. |

Smart battery design reduces failure rates compared to traditional batteries. Traditional lead-acid batteries have a shorter lifespan and longer charging times, which often leads to unexpected failures. In contrast, smart batteries, especially those using lithium-ion chemistries, offer faster charging and longer life. Hospitals that use battery management system-enabled defibrillators have seen a 50% reduction in battery failures compared to those using older technologies.

Note: By adopting smart battery monitoring and advanced battery design, you ensure your medical devices remain operational and safe, even in the most demanding emergency scenarios.

Part2: Smart Battery Management Systems

2.1 Key Features and Functions

You rely on smart battery management systems (BMS) to ensure the safety and performance of lithium battery packs in emergency medical equipment. These systems, such as those described at BMS and PCM, provide advanced monitoring and control for devices like automated external defibrillators. The BMS tracks critical data points, including voltage, current, temperature, and state of charge, to prevent hazards and extend battery life.

Feature | Description |

|---|---|

Battery Monitoring | Tracks battery condition to prevent hazards in devices. |

Safety Protocols | Detects faults and responds to keep devices safe. |

Energy Management | Controls charging/discharging to avoid degradation and optimize performance. |

Communication/Data | Secures battery system information and enables smart diagnostics. |

Thermal Management | Maintains safe temperature ranges for lithium-ion battery packs in devices. |

You benefit from these features in critical medical scenarios, where real-time insights can prevent device failure. For example, automated external defibrillators in hospitals and ambulances depend on BMS to deliver reliable power during emergencies. The BMS uses predictive algorithms to estimate state of charge (SoC) and state of health (SoH), helping you schedule maintenance and avoid unexpected downtime.

Smart monitoring and diagnostics help you detect faults early and predict maintenance needs.

Cell balancing prevents overcharging and extends battery lifespan.

Centralized and distributed BMS architectures impact reliability and fault tolerance.

Tip: Regulatory compliance is essential for BMS in medical devices. Standards like IEC 62133 and UL 1642 verify the safety and reliability of your equipment.

The BMS also supports battery-to-device communications, enabling seamless integration with hospital networks and remote monitoring platforms. This connectivity allows you to access real-time insights and make informed decisions about device readiness.

Functionality | Description |

|---|---|

Monitoring Metrics | Tracks voltage, current, temperature, and SoC for safe operation. |

Predictive Measures | Uses algorithms to estimate SoC, SoH, and state of power. |

Reactive Measures | Implements protective actions against overcharging, overheating, and shorts. |

Real-time Processing | Hardware and software process signals and execute balancing. |

Safety Features | Includes temperature-based controls and intelligent SoC recalibration. |

You see these features in action in automated external defibrillators, where the BMS detects abnormal battery conditions and responds instantly. This rapid response is vital for emergency medical equipment, where every second counts.

2.2 Data Collection and Reporting

You depend on smart BMS to collect and report critical data from your lithium battery packs. The system monitors parameters such as cell health, temperature, charge cycles, system and cell voltage, load current, internal resistance, and more. This data supports operational decision-making and helps you predict battery performance in automated external defibrillators and other emergency medical equipment.

Cell health

Temperature

Charge cycles

System and cell voltage

Load and float current

Internal resistance

State of charge (SoC)

State of health (SoH)

Accurate estimation of SoC and SoH is essential for optimizing battery lifespan and device reliability. You use this information to understand the usable energy remaining in your battery packs, which is vital for effective management in automated external defibrillators. Enhanced SoC and SoH reporting contributes to longer battery lifespan and reduces maintenance costs.

Note: Battery lifetimes can extend from 10 to 20 years in optimal conditions, with a 30% improvement in battery lifetime and a reduction in total cost of ownership by more than 30% when maintenance costs are included.

Smart BMS uses real-time insights and predictive analytics to identify deviations from normal operating patterns. You can detect potential issues like cell imbalances or thermal runaway before they cause failures. Machine learning models, including cloud-based AI, classify battery health conditions with high accuracy, supporting proactive maintenance and reducing the risk of unexpected downtime in automated external defibrillators.

Smart BMS also helps you comply with evolving regulatory requirements. In the EU, batteries in medical devices must be removable and replaceable by end users without special tools by February 18, 2027. Exceptions apply for certain devices, such as professional imaging and in-vitro diagnostics, where specialists can replace the battery. Manufacturers must document any exceptions and ensure compliance with safety, sustainability, and labeling requirements.

All batteries placed on the EU market must comply with EU battery regulations.

Manufacturers, importers, and distributors are responsible for compliance.

Extended Producer Responsibility may require registration in each EU Member State.

You see the impact of these requirements in the development of automated external defibrillators and other emergency medical equipment. By integrating an intelligent battery pack with advanced BMS, you ensure your devices meet international safety standards and deliver reliable performance in critical care.

Callout: Data-driven models, such as Gaussian process regression, help you predict battery electrode mass loading and assess how component parameters influence battery capacity. This approach enhances operational efficiency and supports the development of next-generation battery innovations for emergency medical equipment.

You can apply these smart battery management strategies across other sectors, including robotics, security, infrastructure, consumer electronics, and industrial applications. However, the demands of emergency medical equipment and automated external defibrillators require the highest standards of safety, reliability, and real-time insights.

Tip: By leveraging battery innovations such as remote monitoring, predictive analytics, and a fuel gauging system, you maximize the value of your lithium battery packs and ensure the readiness of your emergency medical equipment.

Part3: Data Communication in Emergency Medical Equipment

3.1 Communication Protocols and Connectivity

You depend on robust data communication protocols to ensure your emergency medical equipment delivers real-time status updates and remote diagnostics. In medical, security, and infrastructure settings, seamless connectivity supports rapid response and patient safety. The following table highlights widely adopted protocols and their advantages:

Protocol | Description | Purpose | Example |

|---|---|---|---|

HL7 | International standards for clinical data exchange | Streamlines sharing and integration of health info | Centralizes patient data in EHR systems |

DICOM | Universal standard for imaging data | Ensures interoperability of imaging data | Transmits patient images in radiology |

IHE | Framework for protocol implementation | Enhances patient care through information exchange | |

IEEE 11073 | Device interoperability standards | Facilitates secure device communication | Used in wearable health monitors |

Low-power, short-range wireless | Transmits health data wirelessly | Connects patient monitors to smartphones | |

Wi-Fi | Wireless networking | Enables high-speed data transmission | Used in telemedicine and hospital systems |

LoRaWAN | Low-power, wide-area networking | Remote monitoring in rural areas |

You face interoperability challenges when integrating these protocols. Fragmented systems can cause compatibility issues, especially during joint operations across agencies. Lack of real-time information may delay critical responses. The absence of standardized protocols often requires technology upgrades, which can increase costs.

To address security and privacy, you rely on features such as network isolation, secure wireless communication, and device authentication. These safety protocols protect patient data and ensure only authorized users access sensitive information.

3.2 Remote Monitoring and Predictive Maintenance

You enhance the reliability of your equipment by using remote monitoring and predictive maintenance. In portable medical devices like ventilators and respiratory devices, cloud-based data monitoring enables clinicians to access real-time data and set alerts for abnormal parameters. Telemonitoring capabilities provide daily communication to secure servers, ensuring data protection and clinician review.

Evidence Description | Key Features |

|---|---|

Cloud-based data monitoring | Enables remote transfer of ventilator data, real-time access, and alerts |

Telemonitoring capabilities | Daily data communication to secure servers for clinician review |

Real-time data collection | Monitors breathing patterns for timely interventions and patient safety |

Remote monitoring devices collect real-time data on patients’ respiratory function.

Timely interventions can be triggered by changes in health status.

Continuous observation enhances security for patients with chronic conditions.

Predictive maintenance reduces unplanned downtime by up to 60%. For example, MRI systems with predictive analytics increase uptime by about 2.5 days per year and cut customer-initiated service requests by 35%. You see similar benefits in lithium battery packs used in emergency medical equipment, where predictive models help you schedule maintenance and avoid failures.

Remote monitoring systems also help you comply with healthcare regulations. Devices must meet FDA, CMS, and HIPAA requirements, ensuring data privacy and legitimate billing. By integrating these systems, you improve patient safety, reduce costs, and maintain operational readiness across all sectors, including medical, security, and infrastructure.

Tip: By leveraging advanced data communication and predictive analytics, you maximize the performance and safety of your equipment, ensuring readiness in every critical scenario.

You transform patient care by adopting smart batteries and advanced data communication in medical equipment. You see these trends:

Solid-state batteries improve patient safety.

Wireless charging increases patient comfort.

Embedded sensors enable real-time patient monitoring.

Benefit | Impact on Patient Care |

|---|---|

Cost Savings | Fewer replacements, better outcomes |

Efficiency | Reliable support for patient devices |

Safety | Proactive patient risk management |

Stay updated on new regulations and battery innovations to keep every patient safe.

FAQ

What advantages do smart battery systems offer for medical equipment in critical care?

Smart battery systems deliver real-time diagnostics, reliable charging, and intelligent power management. You improve device uptime and patient safety in medical, robotics, and security sectors.

How does intelligent power management impact lithium battery packs in medical devices?

Intelligent power management optimizes charging cycles and extends battery life. You reduce maintenance costs and enhance operational reliability for medical, infrastructure, and industrial applications.

Where can you get custom smart battery systems for medical equipment?

You can consult Large Power for custom smart battery systems. Visit this link to discuss lithium battery pack solutions for medical and consumer electronics.