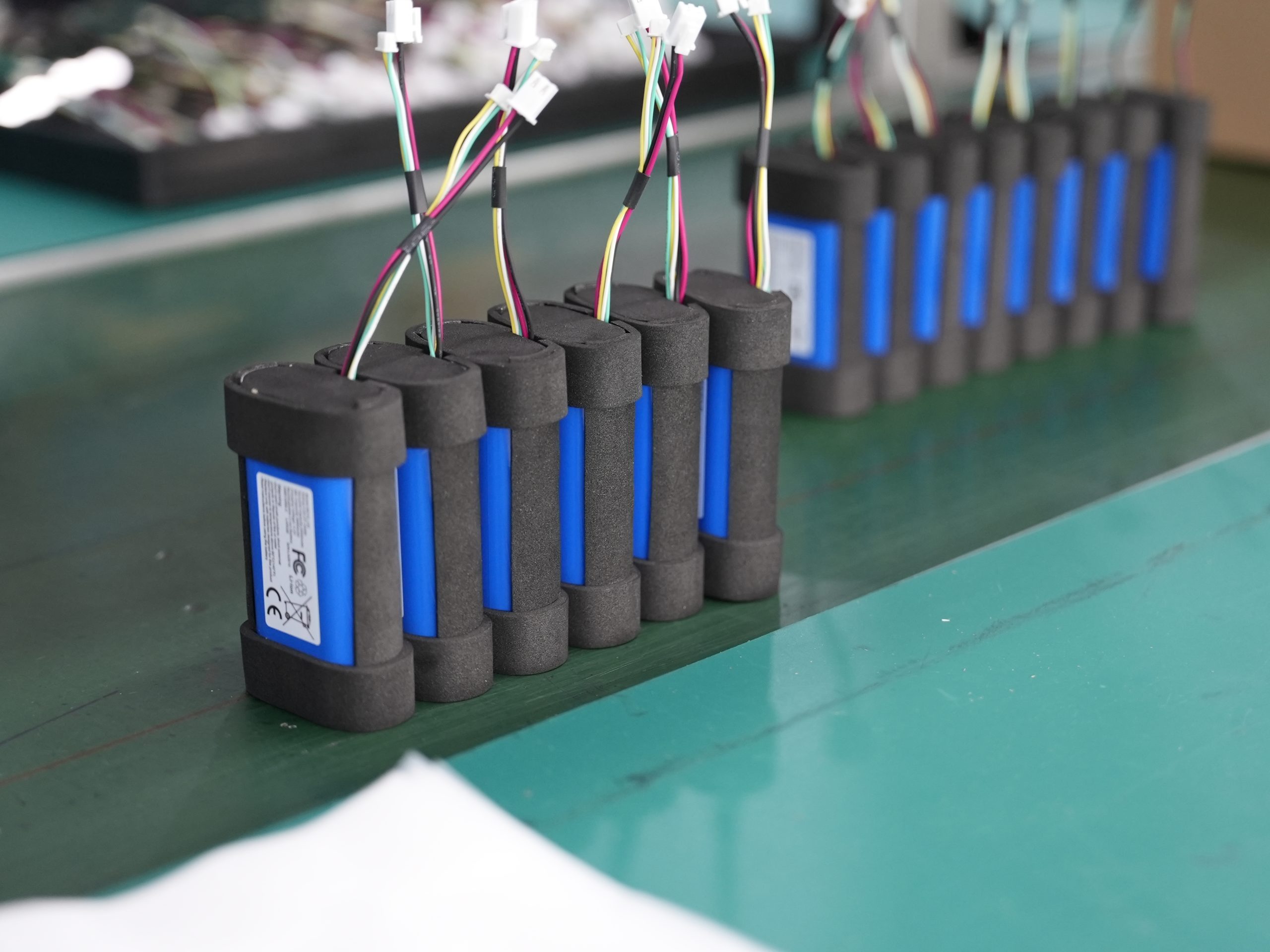

You need reliable performance from your weighing equipment. The smart battery management system gives you real-time control, safety, and efficiency. Modern electronic scales use lithium battery packs because lithium offers high energy density and long cycle life. You see the application of smart bms in every lithium weighing machine battery. These systems track lithium cell health, balance lithium cells, and prevent overcharging. In weighing operations, smart battery management ensures precise results. The application of smart bms extends the service life of lithium weighing machine batteries. You depend on lithium weighing machine batteries for critical weighing in medical, robotics, and industrial sectors. The application of smart bms supports lithium-ion batteries, including LiFePO4, NMC, LCO, LMO, and solid-state lithium metal chemistries. Each lithium weighing machine battery delivers stable platform voltage and consistent weighing accuracy. With smart battery management, your weighing machine battery becomes a dependable asset.

Key Takeaways

Smart battery management systems enhance the performance of lithium weighing machine batteries by optimizing power usage and extending battery life.

Real-time monitoring of critical parameters like temperature and voltage ensures safety and efficiency, preventing issues like overcharging and overheating.

Adaptive charging modes adjust charging rates based on battery conditions, maximizing performance and prolonging battery lifespan.

Using advanced integrated circuits and software algorithms helps maintain battery health, ensuring accurate and reliable weighing results.

Choosing scales with smart battery management features leads to reduced downtime, improved safety, and enhanced operational efficiency.

Part 1: Smart Battery Management Features

1.1 Power Optimization

You rely on smart battery management to maximize the performance of your lithium weighing machine batteries. Power optimization is essential for every weighing operation, especially in medical, robotics, and industrial sectors. Smart battery management systems use several techniques to conserve energy and extend battery life:

Energy conservation methods place system components into low-power or sleep modes when idle.

Strategic energy allocation distributes energy to critical weighing machine battery components, ensuring efficient use of resources.

Optimization of charging and discharging cycles regulates rates to enhance battery longevity and performance.

Smart battery management ensures that lithium weighing machine batteries deliver stable platform voltage and consistent weighing accuracy. You benefit from reduced operational costs because efficient energy usage minimizes downtime and maintenance. Advanced battery management systems can reduce supply chain costs by up to 30%, helping your business achieve carbon-neutral targets.

Lithium Battery Chemistry Comparison

Chemistry | Platform Voltage | Energy Density (Wh/kg) | Cycle Life (cycles) |

|---|---|---|---|

LiFePO4 | 3.2V | 90-160 | 2000+ |

NMC | 3.7V | 150-220 | 1000-2000 |

LCO | 3.6V | 150-200 | 500-1000 |

LMO | 3.7V | 100-150 | 300-700 |

LTO | 2.4V | 70-80 | 7000+ |

Solid-state | 3.7V | 250+ | 2000+ |

Lithium metal | 3.7V | 400+ | 1000+ |

You see the application of smart bms in all these lithium chemistries. Each lithium weighing machine battery type offers unique advantages for weighing in medical, robotics, security systems, and infrastructure.

1.2 Real-Time Monitoring

Smart battery management systems provide real-time monitoring for lithium weighing machine batteries. You track critical parameters to maintain safety and efficiency in every weighing operation. The application of smart bms allows you to monitor:

Temperature

Voltage

Current

Pressure

Humidity

Isolation resistance

Gas detection

Deformation

You use these monitoring features to prevent overcharging and overheating in lithium weighing machine batteries. Real-time monitoring improves safety and operational reliability. The table below shows how monitoring benefits your weighing operations:

Benefit | Explanation |

|---|---|

Instant Weight Measurements | Accurate data enables quick decisions and prevents overloading. |

Enhanced Safety | Reduces risks of equipment damage and workplace injuries. |

Increased Efficiency | Minimizes downtime and boosts productivity. |

Accurate Data Transmission | Provides up-to-date information for operators. |

You depend on smart battery management to ensure that lithium weighing machine batteries perform reliably in medical, robotics, and industrial weighing scenarios. The application of smart bms supports lithium-ion batteries and other chemistries, maintaining platform voltage and weighing accuracy.

Tip: For more details on BMS technology, visit BMS and PCM Solutions.

1.3 Adaptive Charging Modes

You benefit from adaptive charging modes in smart battery management systems. These modes optimize battery charging for lithium weighing machine batteries by adjusting rates based on battery temperature, state of charge, and usage patterns. The application of smart bms uses adaptive charging to prolong battery life and ensure safe, high-performance weighing.

Charging Mode | Time to Equilibrium | Max Voltage Deviation | Final Voltage Discrepancy |

|---|---|---|---|

Dynamic Acceleration Coefficient | 7873s | 1s intervals | ~20mV |

Static Acceleration Coefficient | 10,405s | 1s intervals | 30mV |

Adaptive charging algorithms regulate power input using real-time feedback. You avoid overcharging and battery degradation, which can result from temperature fluctuations and fast charging. This technology balances the need for quicker charging with long-term battery health. By monitoring battery conditions, adaptive charging maximizes performance and lifespan for lithium weighing machine batteries.

Benefit | Description |

|---|---|

Enhanced Battery Lifespan | Intelligent charging strategies prolong battery life, reducing replacements and costs. |

Improved Performance | Optimal battery health leads to better weighing performance and consistent energy. |

Energy Efficiency | Efficient energy utilization minimizes waste and maximizes productivity. |

You see adaptive charging modes in medical, robotics, security systems, and industrial weighing applications. Smart battery management features directly impact your operational costs by optimizing battery performance, extending lifespan, and minimizing downtime.

Part 2: Battery Management Systems in Scales

2.1 Integrated Circuits and Sensors

You depend on advanced integrated circuits and sensors to keep your lithium weighing machine batteries healthy and reliable. These components form the backbone of every smart battery management system. Integrated circuits process signals from sensors that track key parameters in real time. You monitor voltage, current, and temperature for each lithium cell. This monitoring helps you detect early signs of imbalance or failure.

Sensors also measure pressure, humidity, and isolation resistance. You use this data to prevent overheating, overcharging, and unsafe conditions. In medical and robotics applications, you need precise control over battery health. Integrated circuits enable fast response to changes in battery status. You can trust your weighing equipment to deliver accurate results, even in demanding industrial environments.

Note: Integrated circuits and sensors help you maintain the high energy density and long cycle life of lithium weighing machine batteries. You reduce the risk of downtime and extend the service life of your weighing systems.

You face several challenges when implementing smart battery management in electronic scales. These include the increasing complexity of battery architectures, the diversity of lithium chemistries, and strict regulatory requirements. The table below summarizes some of the main challenges:

Challenge | Description |

|---|---|

Real-time state estimation | You must accurately assess the battery’s current state at all times. |

Data security | You need to protect battery data from unauthorized access. |

Temperature management | You must maintain optimal operating temperatures for battery efficiency. |

Charging-discharging | You need to manage charging and discharging cycles to prolong battery life. |

Prediction of battery life | You must estimate how long the battery will last under various conditions. |

Power source availability | You need a reliable power source for the battery management system. |

Disposal issues | You must address the environmental impact of battery disposal. |

You rely on integrated circuits and sensors to address these challenges. They provide the foundation for safe, efficient, and accurate weighing in every sector, from security systems to industrial automation.

2.2 Software Algorithms

You use software algorithms to optimize the performance of lithium weighing machine batteries. These algorithms play a critical role in battery management systems. They monitor individual cell voltages and identify imbalances among cells. When the system detects a difference, the algorithms activate balancing circuits. This process ensures that each cell receives a uniform charge.

Software algorithms monitor cell voltages in real time.

They identify imbalances and trigger balancing circuits.

Uniform charge distribution prolongs battery life and improves performance.

You benefit from these algorithms in several ways. First, you achieve higher accuracy in weighing results. Second, you extend the lifespan of your lithium weighing machine batteries. Third, you maintain consistent energy density and platform voltage, which is vital for applications in medical, robotics, and industrial sectors.

Smart battery management systems use advanced algorithms to optimize charging and discharging cycles. You avoid overcharging and deep discharging, both of which can damage lithium cells. The algorithms also help you predict battery life and schedule maintenance before failures occur.

Tip: Regular software updates keep your battery management systems secure and efficient. You should always use the latest firmware to benefit from improved algorithms and new features.

You face challenges as battery architectures become more complex and as new lithium chemistries emerge. Software algorithms help you adapt to these changes. They ensure that your weighing equipment remains accurate, efficient, and reliable, no matter the application scenario.

Part 3: Accuracy and Efficiency Benefits

3.1 Extended Battery Life

You want your lithium weighing machine battery to last as long as possible. Smart battery management systems help you achieve this goal by monitoring and controlling the charge and discharge cycles. These systems keep your battery within optimal ranges, which prevents overcharging and undercharging. This approach protects the battery and extends its lifespan. You also benefit from battery balancing, which ensures every cell in your lithium pack maintains the same state of charge. This process maximizes the useful capacity of your weighing machine battery and prevents cell damage.

Smart battery management monitors and controls charging and discharging.

Accurate monitoring prevents overcharging and undercharging.

Battery balancing keeps all cells at the same state of charge.

A well-designed system protects against conditions that shorten battery lifespan.

You see these benefits in every application of smart bms, from medical to industrial weighing. You gain a long operational life for your lithium weighing machine battery, which reduces replacement costs and increases uptime.

3.2 Reduced Downtime

You rely on your weighing equipment for continuous operations in sectors like robotics, security systems, and infrastructure. Smart battery management systems use real-time monitoring and predictive analytics to identify potential failures before they happen. This technology allows you to schedule maintenance and avoid unexpected interruptions. Automated control mechanisms adjust charging rates and balance cells, which further reduces the risk of downtime. You maintain high efficiency in your weighing processes and keep your operations running smoothly.

Tip: Predictive analytics in battery management systems help you plan maintenance and prevent costly breakdowns.

3.3 Reliable Weighing Performance

You demand accuracy and better reliability from your lithium weighing machine battery. The application of smart bms ensures stable platform voltage and consistent energy delivery. This stability leads to precise weighing results, even in demanding environments. You improve accuracy and efficiency in every weighing operation, whether you work in medical, industrial, or consumer electronics sectors. Consistent performance means you can trust your weighing machine battery to deliver reliable results every time.

Impact on Weighing Operations | |

|---|---|

Stable platform voltage | Maintains accuracy in all weighing scenarios |

Consistent energy | |

Extended lifespan | Reduces costs and increases operational time |

You see the application of smart bms and lithium chemistries like LiFePO4, NMC, LCO, LMO, solid-state, and lithium metal in every sector. These technologies support your need for accuracy, efficiency, and long-term performance in weighing applications.

Part 4: Weighing Machine Battery Tips

4.1 Best Practices

You can extend the lifespan of your weighing machine battery by following a few essential best practices. Start by storing your battery in a cool, dry place. High temperatures can shorten battery lifespan and reduce performance. Always use the recommended charger for your lithium battery packs. This step prevents overcharging and protects the battery from damage.

Tip: For responsible sourcing and sustainability, review your supplier’s conflict minerals statement and learn about sustainable battery practices.

You can also monitor battery performance using battery management systems. These systems help you track charging cycles and predict when a battery needs replacement. In medical, robotics, and industrial sectors, this approach ensures safety and reliability.

4.2 Choosing Smart Scales

When selecting digital scales or commercial weighing machines, you should prioritize models with advanced battery management systems. Look for scales that support lithium chemistries such as LiFePO4, NMC, LCO, LMO, LTO, solid-state, and lithium metal. Each chemistry offers specific platform voltage, energy density, and cycle life, which impact your weighing machine battery’s lifespan and performance.

Chemistry | Platform Voltage | Energy Density (Wh/kg) | Cycle Life (cycles) |

|---|---|---|---|

LiFePO4 | 3.2V | 90-160 | 2000+ |

NMC | 3.7V | 150-220 | 1000-2000 |

LCO | 3.6V | 150-200 | 500-1000 |

LMO | 3.7V | 100-150 | 300-700 |

LTO | 2.4V | 70-80 | 7000+ |

Solid-state | 3.7V | 250+ | 2000+ |

Lithium metal | 3.7V | 400+ | 1000+ |

You should match your application—whether in security systems, infrastructure, or industrial automation—to the right chemistry. Choose scales with real-time monitoring and adaptive charging features. These features help you maximize battery lifespan and minimize downtime in your commercial weighing machines.

You gain clear advantages when you choose electronic scales with advanced battery management systems. These systems help you improve accuracy and efficiency in every weighing operation. You see longer battery life, better safety, and real-time monitoring. The table below highlights key benefits for your business:

Advantage | Description |

|---|---|

Enhanced Battery Life | Monitors key parameters to prevent overcharging and thermal stress. |

Improved Safety | Prevents hazardous events like short circuits. |

Real-time Monitoring | Gives instant access to voltage, current, and temperature data. |

Predictive Maintenance | Alerts you to maintenance needs before failures occur. |

Enhanced Efficiency | Optimizes energy usage and reduces losses. |

Compliance and Reporting | Generates data logs for regulatory standards. |

You should prioritize smart BMS features and battery health when selecting scales for medical, robotics, security systems, infrastructure, and industrial sectors. In the next five years, you will see new trends such as AI integration and IoT connectivity. These advances will help you achieve even greater accuracy and efficiency in your weighing operations.

FAQ

What advantages do smart battery management systems offer for B2B electronic scales?

You gain real-time monitoring, cell balancing, and adaptive charging. These features extend battery life and improve weighing accuracy. You see fewer interruptions in medical, robotics, security systems, infrastructure, and industrial applications.

How do lithium battery chemistries impact scale performance?

Each chemistry offers unique benefits. For example, LiFePO4 provides 3.2V, 90–160 Wh/kg, and 2000+ cycles. NMC delivers 3.7V, 150–220 Wh/kg, and 1000–2000 cycles. You select the chemistry based on your sector’s needs.

Why is real-time monitoring important for lithium weighing machine batteries?

You detect voltage, current, and temperature changes instantly. This helps you prevent overcharging, overheating, and cell imbalance. You maintain safety and reliability in every weighing operation.

Can smart BMS reduce downtime in industrial weighing systems?

Yes. You use predictive analytics and automated controls to identify issues early. This lets you schedule maintenance and avoid unexpected failures. Your operations stay efficient and productive.

What should you consider when choosing a lithium weighing machine battery for B2B use?

You should match the battery chemistry to your application. For example, LTO offers 2.4V, 70–80 Wh/kg, and 7000+ cycles for high-cycle environments. Always choose scales with advanced BMS for best results.