Servo drives and joint motors demand batteries that handle stringent pulse discharge. You rely on rapid, high-current pulses for precise control and quick response. PWM signals and peak current loads stress lithium battery packs, impacting performance and longevity. The Peukert Effect influences cycle life, making battery selection essential for advanced energy storage solutions.

Key Takeaways

Select lithium battery chemistries like lithium-ion or LiFePO4 for high pulse discharge applications. These batteries provide the necessary power for precise control in servo drives and joint motors.

Implement advanced battery management systems to monitor temperature and balance cell performance. This helps prevent overheating and extends battery life, ensuring reliable operation.

Consider flywheel energy storage systems for applications requiring rapid energy delivery. They offer superior response times and efficiency compared to traditional lithium batteries.

Part 1: Stringent Pulse Discharge Demands

1.1 Pulse Discharge in Servo Motor Systems

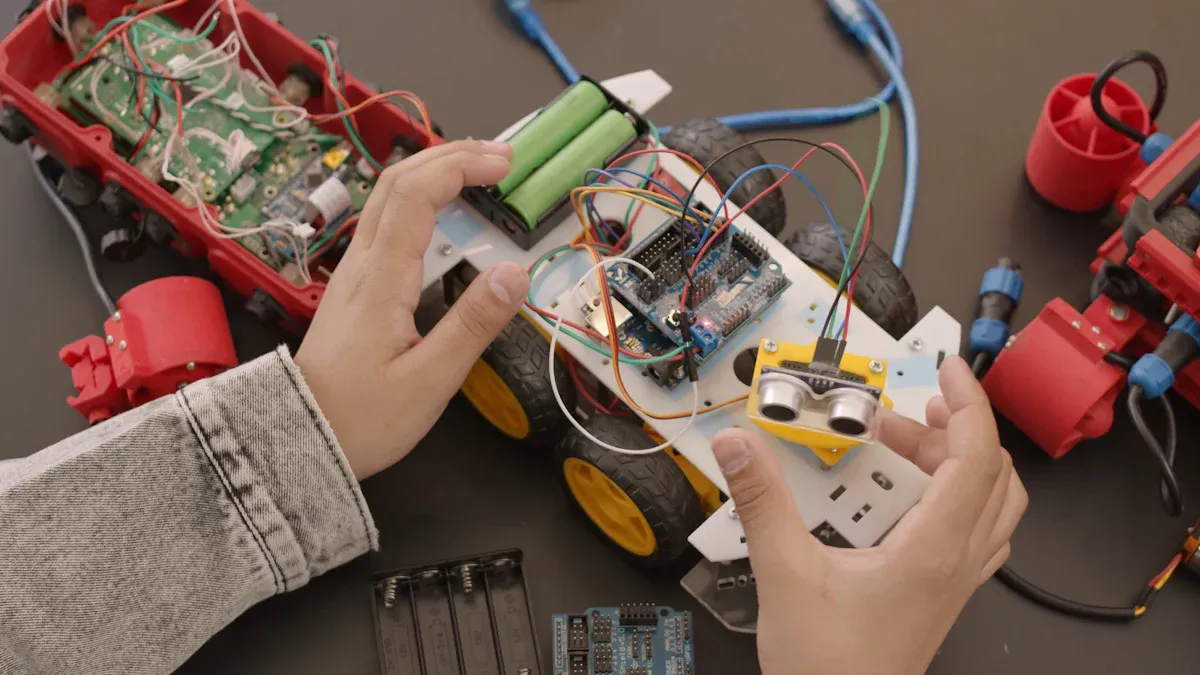

Servo drives and joint motors in sectors such as medical, robotics, security System, infrastructure and industrial rely on stringent pulse discharge capabilities. You need batteries that deliver rapid, high-current pulse bursts to achieve precise motion control and instant torque. Pulse discharge refers to the battery’s ability to supply short, intense bursts of current without significant voltage drop or overheating. In servo motor systems, pulse demand fluctuates with load changes, acceleration, and deceleration cycles. You must select lithium battery packs that withstand repeated pulse events, maintain stable voltage, and avoid excessive heat buildup. Stringent pulse discharge performance ensures your system responds instantly and operates reliably under dynamic conditions.

1.2 Impact of PWM and Peak Currents

Pulse-width modulation (PWM) signals drive servo motors with high-frequency pulse currents. These pulses create rapid switching events, which can stress the battery’s internal resistance and thermal management. You encounter peak current demands during acceleration or sudden load changes, which amplify the need for stringent pulse discharge capability. The PWM charge regulator generates pulse currents that allow low impedance during relaxation intervals, enhancing power transfer and reducing battery stress. This method prevents overheating and overvoltage gassing, improving internal resistance and recharge effectiveness. You benefit from restored battery capacity and reduced frequency of overheating events. However, repeated pulse discharge cycles accelerate aging due to the Peukert Effect, which describes how higher discharge rates reduce available capacity and cycle life. You must monitor pulse discharge rates and optimize battery management systems (BMS) to extend battery longevity and maintain performance.

Tip: Choose lithium-ion, LiFePO4, lithium-polymer, solid-state, or NMC/LCO/LMO/LTO battery chemistries with high platform voltage, energy density, and cycle life for demanding pulse discharge applications.

Part 2: Battery Performance and Technical Challenges

2.1 Voltage Sag and Heat Generation

You face significant technical challenges when deploying lithium battery packs in servo drive and joint motor systems. Voltage sag and heat generation stand out as critical concerns. During high-current pulse events, voltage dips can occur, especially when variable-frequency drives accelerate or decelerate large motors. These voltage sags may cause sensitive equipment to malfunction or shut down, directly impacting operational stability and motor performance. Sudden voltage fluctuations can also trip protective devices, resulting in unnecessary downtime and instability for your servo drive operations.

Heat generation intensifies during pulse discharge cycles. Lithium-ion cells experience accelerated degradation in high-rate discharge applications due to thermal management challenges. Increased lithium loss is attributed to solid electrolyte interphase (SEI) growth, which worsens at higher temperatures. For example, lithium-iron phosphate cells show a 22% and 32% loss in lifetime performance for 2-second and 3-second pulse durations, respectively, as temperature rises to 31°C and 48°C. At a current rate of 0.25C, fresh cell temperature increases by 28.7°C. At 0.5C, the increase reaches 42.4°C. If a cell ages to 90% state of health, the temperature rise at 0.5C is 16.4°C higher than at 0.25C. You must address joule heating effects and improve cell design and thermal management to mitigate these risks.

Note: Environmental factors such as temperature and humidity also affect pulse discharge performance. Lower temperatures reduce reaction rates at the electrode/electrolyte interface, decreasing discharge current and power output. Higher temperatures enhance battery output power but can disrupt chemical balance above 45°C, potentially causing overcharge issues.

2.2 Cycle Life and Peukert Effect

You must consider the impact of repeated pulse discharge on cycle life. Lithium-ion batteries experience increased wear and tear with higher loads, similar to NiMH batteries. Continuous discharge is generally better for battery longevity compared to pulse discharge and heavy momentary loads. High-frequency discharges can lead to capacitor-like behavior, allowing for higher peak currents, but this may not be optimal for cycle life. The Peukert Effect describes how higher discharge rates reduce available capacity and shorten battery life. You need to balance pulse discharge requirements with long-term reliability to maintain consistent motor performance in demanding applications.

2.3 Battery Management Systems

You can optimize battery pack performance and longevity by implementing advanced battery management systems. BMS features play a vital role in mitigating the effects of pulse discharge. The most effective features include:

Feature | Description |

|---|---|

Thermal Management | Regulates battery temperature through constant monitoring and control, utilizing heating-cooling mechanisms to maintain optimal operation, thus maximizing performance and lifespan. |

Cell Balancing | Ensures uniform performance of energy cells by equalizing voltage and state of charge, using active and passive balancing methods to prevent overcharging or undercharging, which enhances efficiency and longevity. |

Intelligent Charging Protocols | Adjusts charging rates based on battery condition, ambient temperature, and usage patterns, minimizing stress on the battery and reducing capacity fade over time, thereby extending battery life. |

Battery management systems dynamically adjust discharge rates to prevent voltage sag and overheating during peak loads. Active thermal management uses external energy sources, such as liquid or air cooling, to control battery temperature and dissipate heat effectively. This rapid adjustment maintains optimal performance, which is crucial in high-demand scenarios like electric vehicles, robotics, and industrial automation.

You should select lithium battery chemistries such as lithium-ion, LiFePO4 , lithium-polymer, solid-state, or NMC/LCO/LMO/LTO for applications requiring stringent pulse discharge. These chemistries offer high platform voltage, energy density, and cycle life, supporting reliable motor performance in Medical, Robotics, Security System, infrastructure, consumer electronics, and industrial sectors.

Tip: Compare lithium battery packs with flywheel energy storage systems to evaluate which solution best meets your pulse discharge and motor performance needs. Flywheel energy storage systems provide rapid energy delivery and high cycle life, making them suitable for applications with frequent pulse demands.

Part 3: Energy Storage Solutions and Best Practices

3.1 Lithium-Ion Battery Advantages

You need batteries that deliver high efficiency for servo drives and joint motors. Lithium-ion batteries provide high platform voltage, energy density, and cycle life. These chemistries support rapid pulse discharge, which is critical for Medical, Robotics, Security System, infrastructure, consumer electronics, and industrial applications. You benefit from high efficiency in demanding environments. LMO batteries, for example, support current pulses from 3.5 to 15 A and operate in temperatures from -55 to 85 °C. You achieve high efficiency with thinner paste and more windings, which improves voltage behavior during short bursts.

Battery Type | Current Pulse Support | Voltage Behavior | Active Material Characteristics |

|---|---|---|---|

LMO | 3.5 to 15 A | Higher initial voltage, short duration | Thinner paste, more windings |

HEV | Varies | Sustains higher voltage briefly | Less active material, designed for short bursts |

You see high efficiency in lithium-ion, LiFePO4, lithium-polymer, solid-state , and NMC/LCO/LMO/LTO chemistries. These batteries deliver reliable pulse discharge and support sustainable transportation and industrial automation.

3.2 Flywheel Energy Storage Systems Comparison

You may consider flywheel energy storage systems (FESS) for applications that require high efficiency and rapid response. FESS deliver superior response times compared to lithium-ion batteries. You gain high efficiency and sustainability benefits, especially in transportation and sustainable transportation sectors. FESS provide instant energy delivery, which is valuable for servo motor systems with frequent pulse demands.

FESS offer significant advancements in energy efficiency over lithium-ion batteries.

You experience superior response times in vehicular and servo motor applications.

FESS support sustainability and efficiency goals for your business.

Solution | Response Time | Energy Efficiency | Sustainability | Application Focus |

|---|---|---|---|---|

Lithium-Ion | Moderate | High | Yes | Broad |

FESS | Instant | Very High | Yes | Pulse-intensive |

3.3 Selection Criteria for Servo Motor Applications

You must select batteries that deliver high efficiency and reliability. Consider the following best practices:

Choose chemistries with high pulse discharge capability, such as lithium-ion, LiFePO4, lithium-polymer, solid-state, or NMC/LCO/LMO/LTO.

Evaluate cycle life, voltage stability, and heat management features.

Use advanced battery management systems for cell balancing and thermal control.

Compare FESS and lithium battery packs for high efficiency and sustainability in your application.

Prioritize solutions that support sustainable transportation and industrial automation.

Tip: Select batteries with proven high efficiency and sustainability for servo drives and joint motors. You improve operational reliability and support sustainable transportation goals.

Feature | Specification |

|---|---|

Tadiran TLI Series | Up to 5A for AA cells |

SiCore | 10C continuous, 20C pulse discharge |

You achieve high efficiency by integrating advanced cell designs and management systems. You support sustainability and efficiency in every application.

You ensure reliable torque and speed in every application by matching battery capabilities to pulse discharge demands. Advanced battery management and careful selection of lithium battery packs or flywheel systems support optimal performance in servo motor applications.

Innovations in battery chemistry, AI-powered analytics, and thermal control drive future efficiency.

Seek customized consultation for your application to maximize operational reliability.

FAQ

What makes lithium battery packs ideal for servo motor and stepper motor applications?

You achieve high torque and high precision control with lithium battery packs. These batteries deliver stable power and cycle life for medical, robotics, and industrial automation.

How does FESS compare to lithium battery packs in current applications of FESS for servo motor systems?

You gain instant power and high torque output with FESS. Lithium battery packs offer longer cycle life and platform voltage. Large Power provides custom battery solutions for integration. Consult Large Power for details.

What challenges do you face when integrating lithium battery packs into servo motor control systems?

You encounter voltage sag, heat generation, and cycle life reduction. Advanced battery management and control system integration help you overcome these challenges in automation.

Tip: For comprehensive analysis of FESS technologies and lithium battery solutions, contact Large Power for expert consultation.