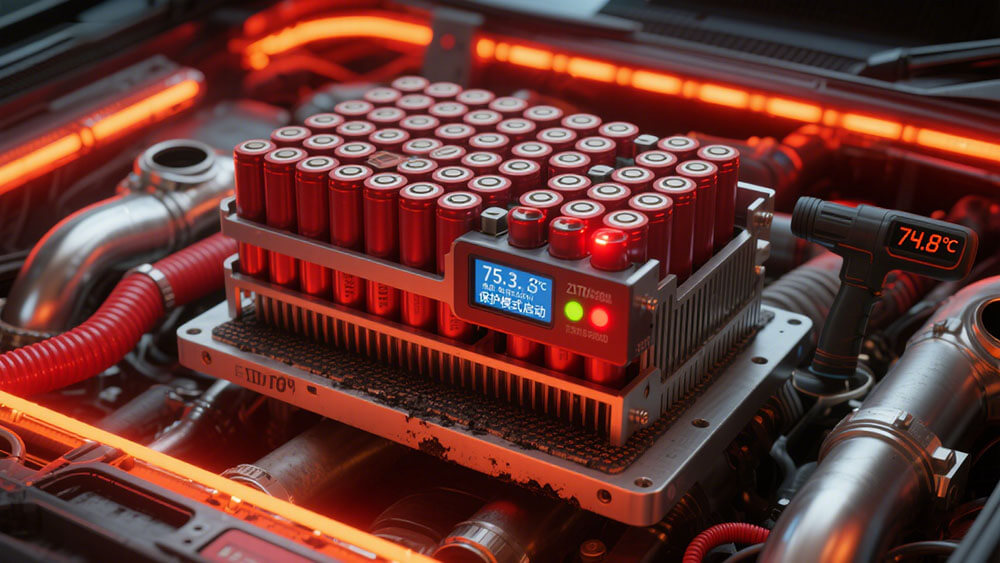

You face a serious hazard when thermal runaway in lithium batteries occurs. This phenomenon means the batteries enter a self-accelerating reaction, causing extremely high temperatures and violent cell venting. Lithium-ion batteries can overcharge or fail, leading to catastrophic events. Recent data shows thermal runaway in batteries disrupts flights each week, proving the risk remains critical.

Key Takeaways

Thermal runaway happens when lithium batteries overheat and trigger a chain reaction that causes fires or explosions.

Early detection using advanced sensors and strong battery management systems can prevent dangerous failures and keep batteries safe.

Using safer materials, good cooling, and smart design reduces risks and helps stop thermal runaway from spreading in battery packs.

Part 1: Thermal Runaway in Lithium Batteries

1.1 Triggers and Causes

You need to understand the main triggers that initiate thermal runaway in lithium batteries, especially when managing battery packs for critical B2B applications such as medical, robotics, security, infrastructure, consumer electronics, and industrial sectors. The triggers fall into two broad categories: external and internal.

You often encounter external triggers such as thermal abuse (exposure to high temperatures), mechanical abuse (crushing, puncture), and electrical abuse (overcharging or overdischarging). These events can rapidly heat the battery, damage internal structures, or force the battery to operate outside safe voltage limits. Internal triggers include manufacturing defects, such as metallic contaminants or faulty separators, and the growth of lithium dendrites during overcharging or high-rate charging/discharging. These issues can cause internal short circuits, which are a leading cause of thermal runaway in batteries.

Tip: Overcharging and high-rate charging/discharging accelerate lithium plating and SEI decomposition, increasing the risk of internal shorts and rapid heat generation. Battery aging and poor assembly also raise the likelihood of failure.

1.2 Chain Reaction Process

Once a trigger initiates thermal runaway in lithium batteries, you face a rapid, self-accelerating chain reaction. This process unfolds in several distinct stages:

Initial Heating: The battery temperature rises quickly, often reaching 150°C to 180°C. This triggers exothermic reactions in the electrolyte and electrode materials.

SEI Breakdown: The solid electrolyte interphase (SEI) on the anode decomposes between 80°C and 120°C, exposing the anode to the electrolyte and releasing heat and gases.

Separator Melting: At around 130°C, the separator melts, causing direct contact between electrodes. This leads to widespread internal short circuits and intense Joule heating.

Electrolyte and Electrode Reactions: The reactions between the exposed electrodes and the electrolyte generate more heat and flammable gases, such as hydrogen, carbon monoxide, and methane.

Pressure Build-Up and Venting: Gases released during thermal runaway increase internal pressure. The battery casing may vent smoke or gas as a warning.

Casing Rupture and Ejection: If pressure continues to rise, the casing ruptures, ejecting hot gases, flames, and sometimes molten metal.

Ignition and Propagation: The flammable gases released during thermal runaway can ignite, causing fire or explosion. The extreme heat can propagate to adjacent cells, especially in densely packed battery modules.

Oxygen Release: Cathode decomposition supplies oxygen internally, sustaining combustion even without external air.

Toxic Gas Emission: Toxic and corrosive gases, such as hydrogen fluoride, are emitted, posing health hazards.

Cascade Effect: The chain reaction can engulf entire battery packs, leading to large-scale fires and explosions that are difficult to extinguish.

Note: The gases released during thermal runaway not only increase the risk of fire but also create toxic and corrosive environments, complicating emergency response.

1.3 Key Risk Factors

You must recognize the key risk factors that increase the likelihood of thermal runaway in batteries, especially in large-scale lithium battery packs:

Internal Short Circuits: Often caused by manufacturing defects, mechanical damage, or lithium dendrite growth.

Elevated Temperatures: High temperatures accelerate SEI decomposition and electrolyte breakdown, releasing heat and gases.

Overcharging: Exceeding safe voltage limits triggers SEI and electrolyte breakdown, increasing the risk of thermal runaway in batteries.

Poor Thermal Management: Inadequate heat dissipation allows heat to accumulate and propagate between cells.

Exothermic Reactions: Chemical reactions within the cells generate heat and flammable gases released during thermal runaway.

Dense Cell Packing: Closely packed cells facilitate heat transfer and cascading failures.

Mechanical Damage: Physical impacts can cause internal short circuits.

Aging and Degradation: Battery aging reduces capacity and increases susceptibility to internal shorts.

Thermal runaway in lithium batteries is extremely difficult to stop once it starts. The internal exothermic reactions generate excessive heat and gases, causing rapid temperature and pressure increases that are hard to dissipate. External sensors often detect warning signs—such as gas release, voltage drop, or surface temperature rise—only after irreversible damage has occurred. The incubation period involves internal mass loss and pressure changes that conventional monitoring cannot detect in time.

Alert: Early detection is critical. Once thermal runaway initiates, the internal heat and gases released during thermal runaway accelerate uncontrollably, leading to fire and explosion. Advanced battery management systems (BMS) with internal temperature and pressure sensors provide the best chance for timely intervention.

System-level design features can help reduce the risk of propagation. You can use phase change composite materials, increase spacing between cells, and incorporate thermal barriers to absorb heat and prevent the spread of thermal runaway in batteries. Robust thermal management systems, such as liquid cooling or hybrid systems, further enhance safety in lithium battery packs.

Part 2: Consequences and Prevention in Lithium-Ion Batteries

2.1 Dangers of Thermal Runaway

You must recognize the severe consequences of battery fires caused by thermal runaway. When a lithium-ion cell fails, it can reach temperatures above 1000°C. This extreme heat spreads rapidly, igniting adjacent cells and causing a chain reaction. The following dangers often occur:

Battery fires and explosions, which are difficult to extinguish and can burn for extended periods.

Release of flammable and toxic gases, including hydrogen fluoride, carbon monoxide, and volatile organic compounds. These gases can exceed safe exposure limits and pose serious health hazards.

Rapid temperature rise and pressure build-up, leading to violent venting or ejection of hot gases and molten materials.

Propagation of failure throughout large battery packs, especially in electric vehicle fires or energy storage systems.

Structural damage to battery enclosures, which can expose more cells to oxygen and external heat.

Alert: Toxic gases from battery fires can spread far beyond the immediate area, making air quality hazardous for first responders and facility personnel.

2.2 Prevention Strategies

You can improve battery safety by adopting multiple prevention strategies. Material improvements play a key role. Use phase-change materials, ceramic coatings, and safer chemistries like Lithium Iron Phosphate (LFP) to enhance thermal stability. Advanced thermal barriers and cooling systems, such as liquid cooling or fan-assisted cooling, help control heat and prevent failures from spreading. Integrate Positive Thermal Coefficient (PTC) materials and thermo-responsive polymers in separators and electrolytes to interrupt conduction during overheating.

Early warning systems are essential for preventing thermal runaway. Off-gas sensors, thermal imaging, and electrical monitoring can detect abnormal conditions minutes before a fire starts. These technologies enable you to take action before damage escalates. For more on responsible sourcing and sustainability, see our Sustainability Statement and Conflict Minerals Statement.

2.3 Battery Management and System Safety

You should implement robust battery management systems (BMS) to monitor voltage, current, and temperature in real time. A well-designed BMS can shut down charging, disconnect faulty cells, and balance voltages to reduce stress on batteries. Advanced BMS solutions also provide wireless monitoring, early fault detection, and integration with fire suppression systems. In battery safety-related applications for industries such as medical, robotics, security systems, and infrastructure, these features are critical.

Best practices for battery safety include:

Maintaining temperature control within recommended ranges.

Using fire detection and suppression systems tailored to your battery type.

Regular inspection and maintenance of battery packs.

Sharing safety data with authorities and insurance providers.

Outsourcing storage to facilities with established safety protocols.

Tip: Advanced monitoring systems with multidimensional sensors can provide early warnings up to several hours before thermal runaway, allowing you to intervene and prevent catastrophic battery fires.

You play a vital role in preventing catastrophic failures in lithium-ion batteries.

Understanding thermal runaway helps you design safer systems and comply with regulations.

Early detection and robust management systems reduce risks and improve reliability.

Stay informed about new safety technologies to protect your operations and people.

FAQ

1. What is the fastest way to detect thermal runaway in lithium battery packs?

You can use advanced sensors in your battery management system. Off-gas detection and real-time temperature monitoring provide early warnings for thermal runaway events.

2. How does Large Power customize lithium battery solutions for industrial applications?

Large Power designs custom battery packs for your specific needs. You can explore custom battery solutions for robotics, medical, and infrastructure projects.

3. Which lithium battery chemistry offers the highest thermal stability?

Chemistry | Thermal Stability | Oxygen Release | Typical Applications |

|---|---|---|---|

Lithium Iron Phosphate (LFP) | High | None | Medical, Security, Infrastructure |

Nickel Manganese Cobalt (NMC) | Moderate | Yes | Consumer Electronics, EVs |

Tip: Choose LFP for maximum safety in high-risk environments.