You need to know the key pros and cons of threaded connection housing of battery when selecting lithium battery packs for your cartridge or trunk. This approach gives you strong safety and flexibility. However, you may notice trade-offs in battery production efficiency, cost, and long-term reliability for each cartridge and trunk application.

Key Takeaways

Threaded battery housings offer strong, secure connections and broad compatibility, making them ideal for applications needing frequent maintenance and flexible setups.

These housings support various materials and allow easy cartridge swaps without special tools, saving time and enhancing safety in industrial and medical devices.

However, threaded housings can slow down production and face reliability issues like thread wear and loosening, so careful assembly and proper materials are essential.

Part 1:Threaded Connection Housing of Battery

1.1 Definition

You often see threaded connection housing of battery in lithium battery packs for industrial, medical, and consumer electronics applications. This design uses a screw or bolt to secure the battery inside its housing, creating a reliable mechanical and electrical connection. This universal threading style ensures broad compatibility, making it simple to swap out a cartridge or battery when you need to test a new device or increase battery capacity. You benefit from secure power transfer, which is essential for tasks that require precision, such as soldering or powering sensitive medical equipment.

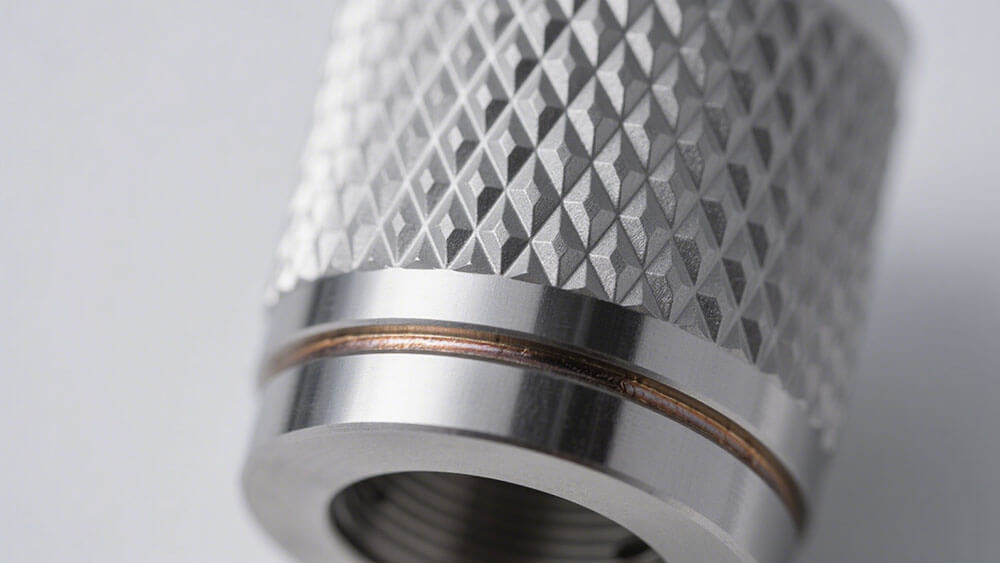

1.2 Structure

A threaded connection housing of battery typically consists of several key components:

Threaded interface: The thread uses a standardized thread pattern, which guarantees compatibility with a wide range of cartridges and devices.

Contact points: These ensure consistent electrical flow between the battery and the cartridge, supporting stable operation and reliable battery capacity.

Housing body: This part holds the battery securely and protects it from external damage.

Sealing elements: Some designs include gaskets or O-rings to improve safety and prevent dust or moisture from entering the housing.

Tip: When you use a threaded connection housing of battery, you can easily replace or upgrade a cartridge without special tools. This flexibility helps you adapt quickly to changing requirements in industrial or consumer electronics environments.

Part 2:Advantages

Threaded battery housings deliver a unique set of benefits for lithium battery packs, especially in demanding B2B environments. You gain secure mechanical and electrical connections, broad compatibility, and enhanced safety features. These advantages make threaded housings a preferred choice for applications that require frequent maintenance, diverse material use, and flexible setups.

2.1 Flexibility

You can adapt threaded battery housings to a wide range of scenarios. This flexibility stands out in small-batch or high-mix production environments, such as industrial automation, robotics, and medical device assembly. When you need to swap a cartridge or adjust battery capacity, the threaded design allows quick changes without specialized tools. This feature supports rapid prototyping and iterative design, which is essential for B2B clients who must respond to evolving project requirements.

Tip: Threaded housings let you pause or adjust your assembly line at any time.

You also benefit from easy integration with battery management systems (BMS), which enhances safety and performance. Threaded connections support overcharge protection, over-discharge protection, and low-voltage protection, ensuring your battery setup meets strict safety standards.

Application Scenario | Flexibility Benefit | Example Use Case |

|---|---|---|

Industrial automation | Quick cartridge swap, easy battery capacity upgrade | Robotics, control panels |

Medical devices | Fast maintenance, secure connection | Portable monitors, diagnostic tools |

Consumer electronics | Modular design, easy repair | Smart home devices, wearables |

2.2 Material Compatibility

Threaded battery housings excel in material compatibility. You can use them with metals, plastics, and composite materials, which is not always possible with alternative housing types. The design supports a variety of threaded inserts, such as key-locking, press-fit, self-tapping, and helical wire types. Each insert type matches different base material properties, including hardness, thermal expansion, and mechanical stress.

You can select self-tapping inserts for soft aluminum or plastic housings.

Key-locking inserts work well for high-strength aerospace or automotive battery boxes.

Helical wire inserts help with thread repair and reinforcement, extending the life of your battery housing.

You can customize insert length and shape to fit miniaturized vape pen or consumer electronics designs.

This adaptability prevents damage to the base material and allows repeated assembly and disassembly. You maintain strong mechanical locking and resistance to vibration, which protects your battery and cartridge from performance loss. Installation controls, such as torque management, further enhance compatibility and safety.

Note: Threaded housings support cartridge compatibility across different product lines. You can use the same battery housing for multiple vape cartridges or battery types, reducing inventory and simplifying your supply chain.

2.3 Convenient for Maintenance

You save time and resources with threaded battery housings. The secure fastening mechanism allows you to replace a battery or cartridge quickly, even during continuous operation. This feature is critical for B2B users in sectors like agriculture drones, industrial robotics, and large-scale infrastructure. You minimize downtime and keep your operations running smoothly.

Threaded housings resist dust, chemicals, and moisture, which increases battery life and reduces maintenance frequency.

Lightweight designs maximize battery performance and flight time for drones or mobile robots.

Additive manufacturing enables you to integrate mounting, connectors, and thermal management into a single part, streamlining your setup and reducing error points.

If you operate in environments with frequent battery swaps, threaded housings offer unmatched convenience. You can maintain high safety standards with built-in safety features, including overcharge protection, over-discharge protection, and low-voltage protection.

You also benefit from easy access to the battery for inspection or replacement. This convenience supports long-term performance and safety, especially in applications where reliability and uptime are critical.

For custom battery solutions tailored to your unique requirements, you can consult with our experts for services.

Part 3:Disadvantages

3.1 Low Production Efficiency

You may notice that threaded battery housings often slow down your assembly process, especially when compared to snap-fit or welded housings. Each screw requires manual or automated tightening, which increases assembly time. In high-volume manufacturing, snap-fit designs allow you to press components together quickly, reducing assembly time by 30%-40% compared to threaded connections. This difference becomes even more significant in confined spaces, such as battery compartments for electric vehicles or robotics. Snap-fit and welded housings also reduce the risk of assembly errors, which can further improve your production efficiency.

When you scale up production, threaded housings require more complex automation systems. You need robotic arms, torque control, and vision systems to ensure proper alignment and tightening. These systems increase your initial investment and maintenance costs. In contrast, snap-fit assemblies use fewer tools and less labor, making them more suitable for high-speed lines. If you operate in a sector where speed and cost control are critical, such as consumer electronics, you may find threaded housings less attractive.

Housing Type | Assembly Speed | Tool Requirement | Automation Complexity | Typical Use Case |

|---|---|---|---|---|

Threaded | Slow | High | High | Industrial, Medical, Robotics |

Snap-fit | Fast | Low | Low | Consumer Electronics, EVs |

Welded | Medium | Medium | Medium | Automotive, Large Packs |

Note: If you need to optimize your battery assembly line for speed and cost, consider the impact of threaded housings on your overall production workflow.

3.2 Unstable Reliability

Threaded battery housings can face reliability issues, especially under vibration or mechanical stress. In industrial and infrastructure environments, you often encounter dynamic loads that challenge the integrity of threaded connections. Without proper locking mechanisms, threads may loosen over time, leading to reduced clamping force and potential joint failure. This can compromise battery performance and safety.

You should also consider the risk of thread stripping, bolt fracture, and galling. These issues arise from overtightening, poor material selection, or repeated assembly and disassembly. For example, if you use softer metals like brass, threads may wear out faster, reducing the lifespan of your battery housing. Stainless steel offers better durability but increases weight, which can affect weight distribution and overall battery weight.

Reliability Issue | Description & Cause | Effect on Battery Housing |

|---|---|---|

Thread Stripping | Shear stress exceeds material strength, overtightening | Loss of thread integrity, failure |

Bolt Fracture | Tensile overload, fatigue, improper material | Complete bolt failure |

Self-Loosening | Vibration causes threads to back off | Gradual loss of preload |

Galling | Friction welds metal threads together | Difficult disassembly, damage |

Corrosion Fatigue | Environmental stress weakens threads | Progressive weakening, failure |

Vibration Loosening | Lack of locking leads to gradual loosening | Reduced clamping force, joint risk |

Advanced analysis shows that threaded connections experience high stress at the thread roots, especially when exposed to both tension and torsion. If you operate in high-vibration settings, you may need to use locking adhesives or spring washers to maintain connection stability. However, these add steps and cost to your assembly process.

Tip: Always follow torque specifications and use locking mechanisms to enhance the reliability and protection of your threaded battery housings.

3.3 Thread Wear

Repeated assembly and disassembly of threaded battery housings can cause thread wear, which impacts long-term durability and battery life. Manufacturers report that softer materials, such as brass, wear out faster than stainless steel. Improper handling, such as cross-threading or over-tightening, can permanently damage threads. This leads to poor engagement, reduced electrical contact, and even arcing, which affects battery performance and safety.

You should also consider the impact of thread wear on maintenance cycles. If your application requires frequent battery swaps, such as in medical devices, thread wear can shorten the usable life of your housing. Over time, worn threads may fail to provide adequate protection or secure fit, increasing the risk of battery failure.

Note: Quality manufacturers provide torque specifications and use durable materials to mitigate thread wear. Emerging alternatives, such as magnetic connections, aim to eliminate this issue entirely.

3.4 Assembly Challenges

You may encounter several challenges when assembling threaded battery housings, especially in high-volume production. Tight tolerances, complex division planes, and the need for long tools in angled designs all increase assembly complexity. Bolt holes can weaken the structural profile of your battery housing, and improper placement may compromise leak tightness. These factors can affect both the weight and weight distribution of your battery pack, which is critical for applications like robotics and drones.

Common assembly challenges include:

Notch-design division planes require very low tolerances, increasing complexity.

Bolt connections on the housing lid surface risk leak tightness.

Horizontal and angled division planes need long tools, complicating assembly.

Bolt holes reduce usable surface area and structural strength.

To address these issues, you should:

Keep tolerances realistic to avoid excessive cost and difficulty.

Use commercial off-the-shelf parts to simplify assembly.

Choose parts that are easy to handle and manipulate.

Minimize the number of different parts and sizes.

Design modular assemblies for easier and faster assembly.

Modern assembly equipment, such as force-monitoring presses and automated alignment verification, can help reduce errors and improve consistency. Operator training and quality control measures are also essential for maintaining high assembly standards.

For custom battery solutions that address your unique assembly and performance needs, consult our experts for services: custom battery consultation.

You gain strong reliability and flexibility with threaded connection housings for trunk mounted battery packs. However, you face higher costs and lower efficiency compared to other trunk solutions. See the table below for a quick comparison:

Criteria | Threaded Connection Housings | Other Housing Types |

|---|---|---|

Cost | Higher | Lower |

Installation Efficiency | Moderate | High |

Reliability | High | Medium |

Choose trunk battery housings based on your actual battery needs.

Use modular trunk designs for easier maintenance.

Collaborate early with manufacturers to optimize trunk mounted battery solutions.

FAQ

1. What industries benefit most from threaded battery housings?

You see the greatest benefits in medical devices, robotics, industrial automation, and infrastructure projects. These sectors require secure connections and frequent maintenance for lithium battery packs.

2. How do threaded housings impact lithium battery sustainability?

Threaded housings support easy disassembly and recycling. You can learn more about sustainable battery practices in our sustainability approach.

3. Where can you get custom threaded battery solutions for your business?

You can contact Large Power for tailored lithium battery pack solutions. Our team provides expert consultation and OEM/ODM services for your unique requirements.