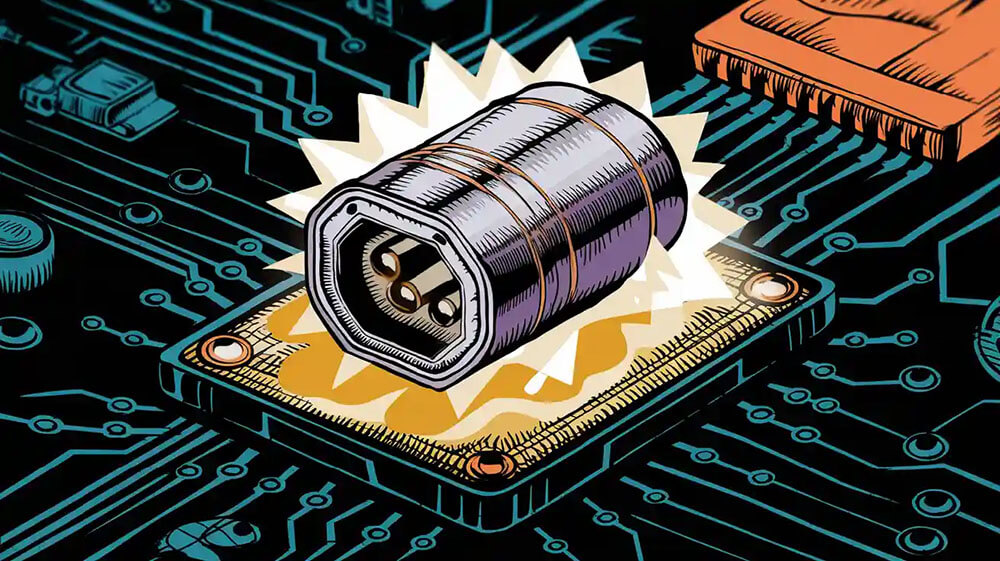

UL 1977 and Lithium Battery standards set the benchmark for safe and reliable connectors. These standards ensure your lithium battery systems operate efficiently and meet regulatory requirements. By addressing critical aspects like electrical performance and environmental durability, they protect users and enhance the longevity of battery-powered devices.

Key Takeaways

Use safe materials that stop overheating and electrical problems in battery connectors.

Test connectors well to keep energy flow steady and make them last longer.

Follow rules to make certifications easier and gain customer confidence in your products.

Part 1: Overview of UL 1977 and Lithium Battery Applications

1.1 What Are UL 1977 Standards for Connectors?

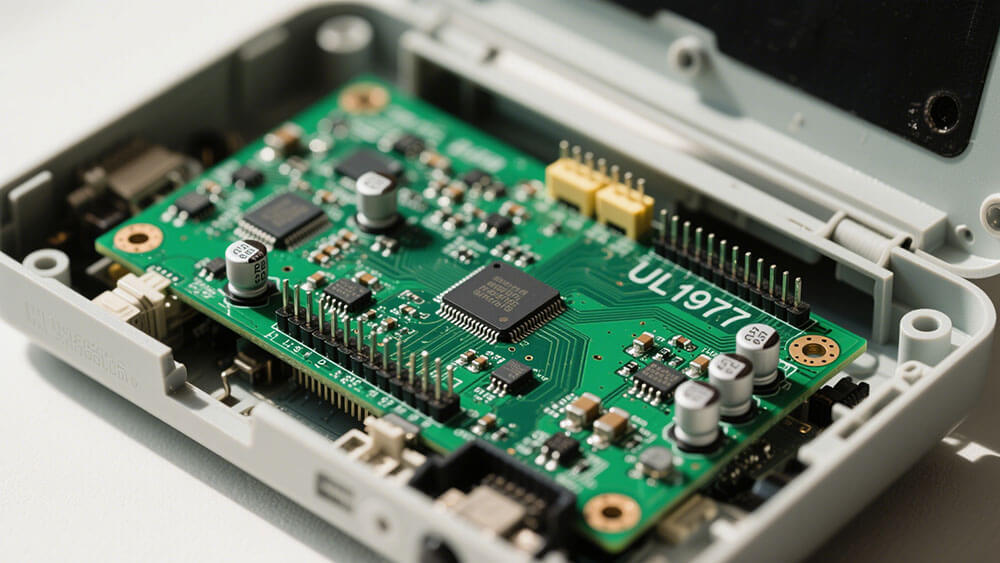

UL 1977 standards define the safety and performance requirements for connectors used in various electrical systems. These standards apply to single and multipole connectors designed for factory assembly with copper or copper alloy conductors or printed wiring boards. They cover applications in data, signal, control, and power systems. The goal is to ensure that connectors meet stringent criteria for reliability and safety.

For lithium battery systems, UL 1977 ensures that connectors can handle the unique demands of high-energy environments. This includes maintaining electrical integrity during charging and discharging cycles. By adhering to these standards, you can ensure that your connectors perform consistently under various operating conditions.

1.2 Scope of UL 1977 in Lithium Battery Systems

UL 1977 and lithium battery applications intersect in critical ways. These standards address the specific needs of connectors in battery systems, such as high current flow and thermal management. They also evaluate the connectors’ ability to withstand environmental factors like temperature fluctuations and humidity.

For manufacturers, UL 1977 compliance ensures that connectors meet industry benchmarks for safety and performance. This is especially important in lithium battery systems, where even minor failures can lead to significant risks. By designing connectors that align with UL 1977, you can enhance the reliability and longevity of your battery-powered devices.

Part 2: Key Requirements and Testing Procedures for Battery Connectors

2.1 Safety Standards for Lithium Battery Connectors

Safety standards for lithium battery connectors play a critical role in preventing hazards during operation. UL 1977 outlines stringent requirements to ensure connectors meet safety benchmarks. These standards focus on minimizing risks such as overheating, electrical arcing, and short circuits.

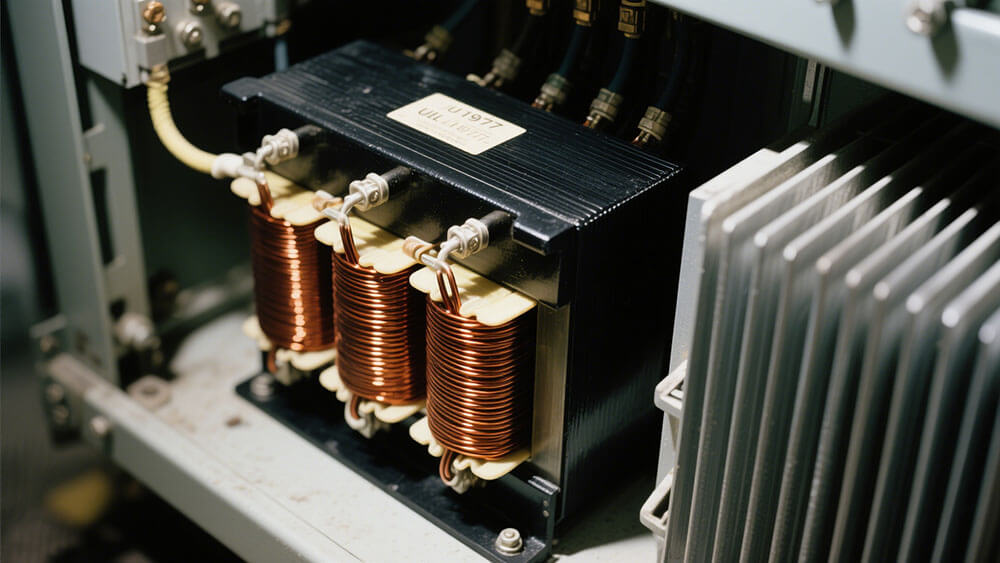

You must prioritize the use of materials that resist high temperatures and maintain electrical integrity. For example, copper nickel connectors are often chosen for their durability and ability to handle demanding conditions. Flexible connectors also contribute to safety by accommodating movement and reducing stress on connection points.

Tip: Always verify that your connectors comply with UL 1977 safety standards to avoid costly recalls or system failures.

2.2 Performance Testing for Charging Connectors

Performance testing evaluates how charging connectors function under real-world conditions. UL 1977 requires rigorous testing to ensure connectors can handle high current performance during charging cycles. This includes assessing their ability to maintain stable connections and support efficient energy transfer.

High-current charging connectors undergo tests to measure their capacity to withstand prolonged charging sessions without degradation. You should also consider the compatibility of connectors with various battery systems to ensure seamless operation.

Testing procedures often simulate extreme conditions, such as rapid charging and discharging cycles, to verify reliability. By conducting these tests, you can identify potential weaknesses and improve the design of your charging connectors.

2.3 Electrical and Mechanical Testing Under UL 1977

Electrical and mechanical testing ensures connectors meet the demands of lithium battery systems. UL 1977 specifies tests to evaluate electrical conductivity, insulation resistance, and mechanical durability.

You should focus on connectors that maintain consistent electrical performance, even under high current loads. Copper nickel connectors are particularly effective in achieving this due to their excellent conductivity and resistance to corrosion. Mechanical testing assesses the connectors’ ability to withstand physical stress, such as vibrations and impacts, without compromising functionality.

Note: Proper electrical and mechanical testing not only ensures compliance but also enhances the reliability of your battery systems.

2.4 Environmental Testing for Battery Applications

Environmental testing examines how connectors perform under various environmental conditions. UL 1977 requires tests for temperature extremes, humidity, and exposure to corrosive elements. These tests ensure connectors remain functional and reliable in challenging environments.

Flexible connectors are often preferred for their adaptability to temperature fluctuations and physical movement. High-current charging connectors must also demonstrate resilience in harsh conditions to maintain consistent performance.

You should conduct environmental testing early in the design process to identify potential vulnerabilities. This proactive approach helps you create connectors that meet UL 1977 standards and deliver long-term reliability.

Part 3: Practical Implications for Manufacturers and Designers

3.1 Benefits of UL 1977 Compliance for Battery Systems

Adhering to UL 1977 standards offers significant advantages for manufacturers and designers of lithium-ion battery systems. Compliance ensures that your connectors meet stringent safety and performance benchmarks, which directly enhances the reliability of your products. This reliability translates into fewer failures, reducing the risk of costly recalls or reputational damage.

One of the most critical benefits is improved energy efficiency. UL 1977-compliant connectors are designed to minimize energy loss during charging and discharging cycles. This optimization not only boosts battery efficiency but also extends the lifespan of the batteries. For applications like battery-powered industrial trucks, where consistent performance is crucial, this can make a substantial difference in operational productivity.

Compliance also simplifies the certification process for your products. By meeting UL 1977 standards, you align with industry regulations, making it easier to gain market approval. This can accelerate your time-to-market and give you a competitive edge. Additionally, customers often prefer products that adhere to recognized standards, as they offer a higher level of trust and assurance.

Tip: Investing in UL 1977 compliance upfront can save you time and resources in the long run. It ensures your connectors perform reliably under various conditions, enhancing customer satisfaction and loyalty.

3.2 Challenges in Meeting UL 1977 Standards

While the benefits of UL 1977 compliance are clear, achieving it can be challenging. One of the primary hurdles is designing connectors that meet the rigorous safety and performance requirements. For instance, connectors must handle high current loads without overheating or degrading, which requires careful material selection and engineering precision.

Environmental testing poses another challenge. Your connectors must perform reliably under extreme conditions, such as high humidity, temperature fluctuations, and exposure to corrosive elements. Meeting these requirements often involves extensive testing and iterative design improvements, which can be time-consuming and costly.

Balancing energy efficiency with durability is another critical challenge. While you aim to maximize battery efficiency, you must also ensure that the connectors can withstand mechanical stress and maintain electrical integrity over time. This balance requires innovative design solutions and advanced manufacturing techniques.

Note: Collaborating with experts in UL 1977 standards can help you navigate these challenges effectively. They can provide valuable insights and guidance, ensuring your connectors meet all requirements without compromising on performance or efficiency.

UL 1977 standards are essential for ensuring the safety and performance of lithium battery connectors. They provide a framework that helps you design reliable and efficient systems.

Key Takeaways:

Enhanced Safety: Minimize risks like overheating and electrical failures.

Improved Performance: Ensure consistent energy transfer and durability.

Regulatory Compliance: Simplify certification and gain customer trust.

Pro Tip: Partner with UL 1977 experts to streamline compliance and optimize your designs. Prioritize adherence to these standards to deliver safer, more reliable battery systems.

FAQ

1. What materials are best for lithium battery connectors?

Copper and nickel are ideal. Copper offers excellent conductivity, while nickel enhances durability and resists corrosion in demanding environments.

2. How does UL 1977 ensure connector reliability?

UL 1977 mandates rigorous testing for conductivity, mechanical strength, and environmental resilience, ensuring connectors perform consistently under high current loads and extreme conditions.

3. Why is environmental testing important for battery connectors?

Environmental testing verifies connectors’ ability to withstand temperature changes, humidity, and corrosive elements, ensuring long-term reliability in diverse applications.

Tip: For professional guidance on environmental testing, visit Large Power.