You face strict safety standards when integrating 3S–12S lithium battery packs into Medical devices. UL/iec medical certifications and battery pack certifications help you meet these safety standards. UL certification supports North American compliance, while global markets demand IEC. These measures reduce risk and boost reliability.

Key Takeaways

UL and IEC certifications ensure safety and reliability for lithium battery packs in medical devices. Meeting these standards helps you gain trust from manufacturers and access global markets.

Implementing robust safety features, such as thermal management and overcharge protection, is essential for compliance. These features enhance the safety of your battery packs and reduce risks.

Planning for certification early in the design process can save time and costs. Using pre-certified components streamlines the certification process and helps you meet regulatory requirements efficiently.

Part1: UL/IEC Medical Certifications and Battery Pack Requirements

1.1 UL Certification Standards

You must understand UL certification requirements before designing lithium battery packs for medical devices. UL sets safety standards that address electrical, mechanical, and environmental risks. UL 2054 and UL 62133 are the most relevant standards for battery pack certifications in medical applications. UL 2054 covers household and commercial battery safety requirements, while UL 62133 focuses on rechargeable cells and batteries, including lithium-ion and lithium-polymer/LiPo chemistries.

UL certification requires you to implement robust safety features, such as overcharge protection, thermal management, and short-circuit prevention. You must select components that meet strict safety standards and follow detailed testing protocols. UL evaluates your battery pack for electrical insulation, enclosure integrity, and fire resistance. You must document your design and manufacturing processes to demonstrate compliance with UL certification requirements.

Tip: UL certification helps you reduce liability and improve reliability. You gain easier access to North American markets and build trust with medical device manufacturers.

1.2 IEC Certification Criteria

IEC certification requirements apply to global markets. IEC 62133 is the primary standard for rechargeable lithium battery packs in medical devices. IEC certification covers similar safety standards as UL, but you must also address international regulatory compliance. IEC standards require you to test for electrical, mechanical, and environmental hazards. You must verify battery safety under extreme conditions, such as high temperature, vibration, and impact.

IEC certification requires you to use standardized lithium battery chemistries. The most common types include:

Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) |

|---|---|---|---|

3.2 | 90–140 | 2000–5000 | |

NMC | 3.7 | 150–220 | 1000–2000 |

LCO | 3.7 | 150–200 | 500–1000 |

LMO | 3.7 | 100–150 | 300–700 |

LTO | 2.4 | 70–110 | 7000–20000 |

You must select the right chemistry based on your application’s safety standards and reliability needs. IEC certification also requires you to implement a battery management system for monitoring and protection.

Note: IEC certification gives you access to global markets and ensures your products meet international safety requirements.

1.3 UN38.3 and Transport Safety

You must comply with UN38.3 certification requirements to ensure transport safety for lithium battery packs. UN38.3 sets safety standards for shipping batteries by air, sea, and land. You must test your battery packs for altitude simulation, thermal cycling, vibration, shock, external short circuit, impact, overcharge, and forced discharge.

UN38.3 certification helps you prevent accidents during transportation. You must label and package your batteries according to international safety standards. You must provide documentation that proves compliance with transport safety regulations.

Key UN38.3 Tests:

Altitude Simulation

Thermal Test

Vibration

Shock

External Short Circuit

Impact

Overcharge

Forced Discharge

You must pass all UN38.3 tests before shipping lithium battery packs. UN38.3 certification requirements protect you from regulatory penalties and ensure safe delivery to customers.

Alert: Failing to meet UN38.3 transport safety standards can result in shipment delays, fines, or product recalls. You must prioritize battery safety and regulatory compliance throughout your supply chain.

Part2: Design, Manufacturing, and Safety Impacts

2.1 Design Changes for Certification

You must adapt your design to meet UL/IEC certifications and battery pack certifications. These changes help you comply with safety standards and certification requirements for lithium battery packs in medical, robotics, and security system applications. You need to integrate safety features that address thermal management, cell spacing, and venting systems. You must select the right cell chemistry and use pre-certified components to streamline the certification process.

The following table summarizes the most common design modifications required for ul certification and IEC certification:

Design Modification | Purpose |

|---|---|

Integrate thermal management | Prevents thermal runaway and ensures safety during operation. |

Maintain proper cell spacing (min 2mm) | Reduces risk of short circuits and enhances safety. |

Implement controlled venting systems | Allows for safe gas release during thermal events, preventing pressure build-up. |

Choose appropriate cell chemistry | NMC cells provide better thermal stability compared to NCA cells. |

Use pre-certified components | Reduces testing time and sample requirements for certification. |

Implement comprehensive BMS | Ensures advanced monitoring and compliance with safety standards. |

Plan for multiple certifications | Addresses specific testing protocols for various markets (UN38.3, IEC 62133-2, UL, CE). |

You must plan for multiple certifications to achieve global market access. Each certification has unique requirements and testing protocols. You need to consider the cost and timeline for each certification. The table below shows the estimated cost and test timing for major certifications:

Certification | Estimated Cost | Test Timing |

|---|---|---|

CE | $500 – $1,000 | 4 – 6 weeks |

IEC | $6,000 – 10,000 | 6 – 8 weeks |

UL | $15,000 – 20,000 | 10 – 12 weeks |

UN38.3 | $5,000 – 7,000 | 4 – 6 weeks |

Tip: You can reduce development time and cost by using pre-certified components and planning for certification requirements early in your design process.

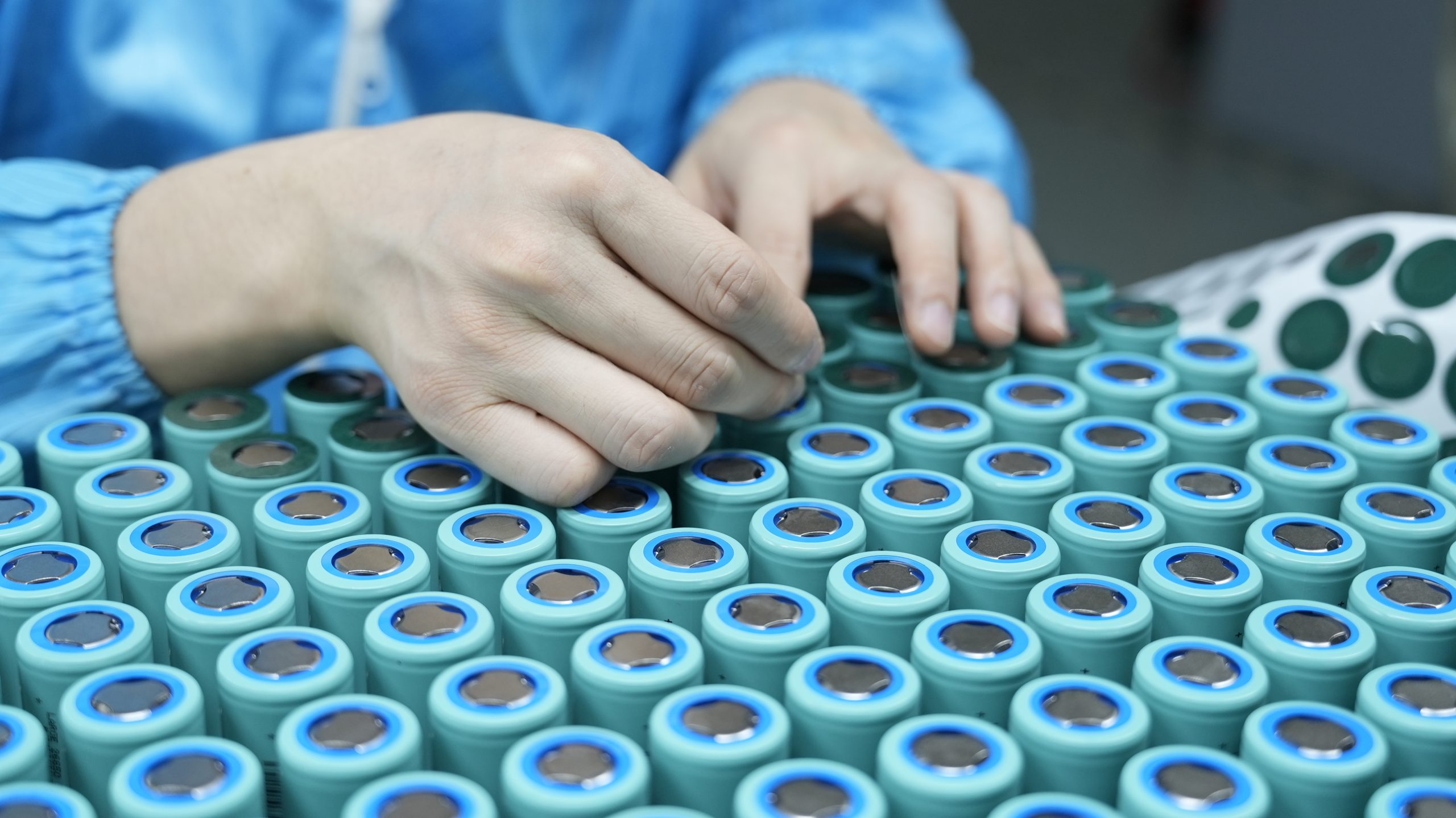

2.2 Material and Testing Protocols

You must select materials that meet strict safety standards and certification requirements. For medical devices, you need to choose lithium battery packs with chemistries that offer high reliability and safety. NMC, LiFePO4, and LTO are popular choices due to their stable performance and long cycle life.

You must follow mandated testing protocols for ul certification and IEC certification. These protocols verify battery safety and reliability under various conditions. You need to conduct tests for external short circuit, overcharging, thermal abuse, mechanical stress, and fire exposure. The main testing protocols include:

IEC 62133-2: Focuses on safety and performance testing for rechargeable Li-ion cells in portable applications, including tests for external short circuit, overcharging, and thermal abuse.

UL 2054: Addresses safety for battery packs, including electrical tests, mechanical stress tests, and fire exposure tests to ensure the safety of the entire system.

You must document all test results and maintain traceability for regulatory compliance. You need to ensure that your lithium battery packs pass all required tests before entering the market.

Alert: Failing to meet testing protocols can delay product launch and limit global market access.

2.3 Safety and Reliability Improvements

You improve safety and reliability by meeting ul/iec medical certifications and battery pack certifications. You must implement advanced safety features such as comprehensive battery management systems, controlled venting, and robust thermal management. These features help you prevent thermal runaway, short circuits, and fire hazards.

You must maintain proper cell spacing and use high-quality materials to meet safety standards. You need to verify battery safety through rigorous testing protocols. You must ensure transport safety by complying with UN38.3 certification requirements for shipping lithium battery packs in industrial, infrastructure, and consumer electronics sectors.

You gain higher reliability and reduce risk by following certification requirements. You build trust with medical device manufacturers and achieve global market access. You also protect your business from regulatory penalties and product recalls.

Note: You must prioritize battery safety and regulatory compliance throughout your design, manufacturing, and supply chain processes.

Part3: Regulatory and Market Advantages

3.1 Global Market Access

You gain access to international markets when you meet ul/iec medical certifications and battery pack certifications. UL certification opens doors in North America, while IEC standards support global acceptance. You must comply with safety standards to satisfy regulatory bodies in each region. UL certification requirements ensure your lithium battery packs meet strict safety and reliability benchmarks. You also need to pass transport safety protocols, such as UN38.3, to ship products worldwide. By achieving certification, you reduce barriers to entry and expand your reach in the medical device sector.

3.2 Compliance and Differentiation

You stand out in the competitive medical device market by meeting certification requirements. UL certification and IEC standards demonstrate your commitment to safety standards and reliability. Healthcare providers prefer certified lithium battery packs because they trust the product’s safety and performance. You also show innovation by integrating advanced safety features, such as thermal management and overcharge protection. The following table highlights how certification helps you differentiate your products:

Key Aspect | Description |

|---|---|

Regulatory Compliance | Ensures adherence to safety standards set by agencies like the FDA and ISO 13485. |

Product Safety and Reliability | Compliance enhances trust among healthcare providers, making certified products more appealing. |

Innovation in Safety Features | Companies focus on innovations such as thermal management and overcharge protection to meet standards. |

Tip: You build a reputation for reliability and safety when you prioritize battery pack certifications.

3.3 Overcoming Certification Challenges

You face several challenges during the UL certification and IEC certification process. Misinterpretation of standards often leads to compliance issues. Inadequate risk assessment can cause you to overlook critical safety measures. The complexity of compliance increases when you target multiple markets with different certification requirements. You must also address transport safety for global shipments. Common challenges include:

Misunderstanding the scope of IEC standards can lead to applying irrelevant standards.

Focusing only on basic tests while neglecting critical tests for thermal runaway.

Seeking operational certification without prior transport safety certification can cause delays.

The table below summarizes the main obstacles manufacturers encounter:

Challenge Type | Description |

|---|---|

Misinterpretation of standards | Manufacturers often misunderstand the various overlapping standards, leading to compliance issues. |

Inadequate risk assessment | A lack of thorough risk assessment can result in overlooking critical safety measures. |

Complexity of compliance | Different markets have varying certification requirements, complicating the compliance process for manufacturers. |

Note: You can overcome these challenges by working with experienced certification partners, planning for certification requirements early, and maintaining clear documentation throughout the process.

You strengthen safety standards and reliability by prioritizing UL certification and compliance testing for lithium battery packs. Performance testing supports global market access and regulatory approval. The table below highlights how agencies and healthcare providers value certified batteries for medical devices.

Evaluation Focus | Benefit for Manufacturers |

|---|---|

Safety and Usability | Enhanced trust and marketability |

Regulatory Compliance | Streamlined approval and reduced risk |

FAQ

What are the main benefits of UL/IEC medical certifications for lithium battery packs?

You improve safety, reliability, and market access. UL/IEC certifications help you meet regulatory requirements and build trust with medical device manufacturers.

How do lithium battery chemistries compare for medical applications?

Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) |

|---|---|---|---|

LiFePO4 | 3.2 | 90–140 | 2000–5000 |

NMC | 3.7 | 150–220 | 1000–2000 |

LTO | 2.4 | 70–110 | 7000–20000 |

Where can you get custom-certified lithium battery packs for medical devices?

You can contact Large Power for custom lithium battery pack solutions. The team provides expert consultation and supports UL/IEC medical certifications.