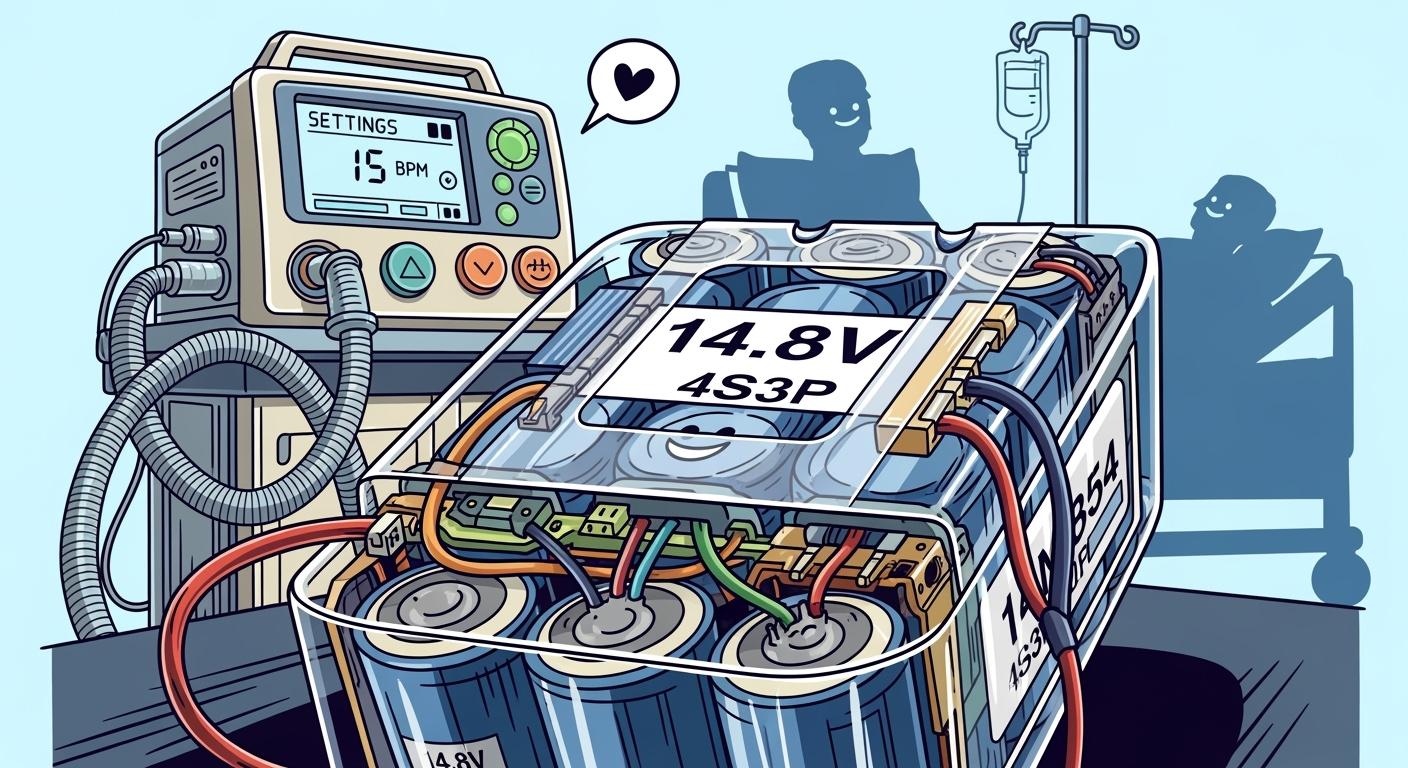

You depend on portable ventilators to deliver Uninterrupted Life Support for patients in critical situations. When a battery fails, ventilation can stop suddenly, putting lives at risk. In clinical settings, battery-related issues often cause device failures during patient transport. A 14.8V 4S3P (18650) battery with NMC chemistry gives you a reliable and compliant power source. Careful battery design protects patient safety and ensures top device performance. Meeting strict medical standards pushes you to solve unique technical and regulatory challenges in every lithium battery pack.

Key Takeaways

Choose high-quality lithium battery packs to ensure reliable power for portable ventilators. This choice enhances patient safety and device performance.

Implement a robust Battery Management System (BMS) to monitor battery health. A BMS prevents overcharging and extends battery life, ensuring uninterrupted operation.

Prioritize safety features like thermal management and physical protection in battery design. These features prevent overheating and damage, supporting safe use in medical environments.

Regularly maintain and test battery packs to identify issues early. Scheduled checks improve reliability and help avoid unexpected failures during critical situations.

Ensure compliance with medical standards and obtain necessary certifications. Meeting these requirements protects your organization from legal risks and enhances product credibility.

Part1: Life Support Battery Requirements

1.1 Reliability and Safety

You rely on ventilator batteries to deliver consistent power in every situation. Reliability means the battery must perform without interruption, even during patient transport or emergencies. Safety comes first in medical environments. You need lithium battery packs with advanced protection against overcharge, over-discharge, and short circuits. NMC chemistry offers a stable platform voltage, higher energy density, and long cycle life. These features help you maintain Uninterrupted Life Support for patients who depend on ventilators.

Tip: Choose battery packs with built-in safety circuits and robust cell balancing to prevent failures and extend service life.

1.2 Runtime and Power Output

You must ensure that ventilator batteries provide enough runtime and power output for critical care. Most transport ventilators require batteries that last over 10 hours, even when running compressors and delivering PEEP. This extended runtime supports patient safety during long transfers and emergency situations. High-capacity lithium battery packs, such as those rated at 11Ah or more, deliver stable voltage and reliable energy output.

Typical requirements for ventilator batteries:

Runtime: Over 10 hours with full operation

Stable voltage for sensitive medical electronics

Sufficient power for compressors and advanced ventilation modes

1.3 Redundancy Features

Redundancy protects you from unexpected power failures. Medical-grade lithium battery packs often use intelligent monitoring systems that collect data and detect issues before they affect patient safety. You benefit from proactive maintenance and early failure detection, which extends battery life and reliability.

Redundancy Type | Description | Advantages | Disadvantages |

|---|---|---|---|

N+1 | One additional spare component to handle failures. | Reduces hardware costs. Easy to implement. Provides backup for a single failure. | Risk of system failure if the spare fails. Less efficient for larger systems. |

2N | Complete duplication of the system. | No single point of failure. Can handle multiple component failures. Ideal for high availability. | Higher costs for hardware and maintenance. More complex to manage. |

You also see automatic transfer switches (ATS) in some systems. When the main power fails, the ATS switches the load to an emergency power source. Once power returns, the switch restores the load to the primary source. These features ensure continuous operation and support Uninterrupted Life Support in every scenario.

Part2: 14.8V 4S3P (18650) Configuration

2.1 Voltage and Parallel-Series Design

You need a battery pack that delivers stable voltage and scalable capacity for portable ventilators. The 14.8V 4S3P configuration achieves this by connecting four cells in series (4S) to reach the required platform voltage, while three parallel strings (3P) boost total capacity. This design supports medical devices that demand consistent power output and long runtime. You can scale the pack by adjusting the number of parallel strings, making it flexible for different ventilator models and other medical equipment.

Note: The 14.8V platform matches the voltage requirements of many medical electronics, ensuring compatibility and reducing conversion losses.

2.2 18650 Cell Advantages

You benefit from using 18650 cells in medical battery packs. These cells offer high energy density, compact size, and proven reliability. The 18650 format supports portable designs and fits easily into ventilator housings. You gain:

High energy density (150–250 Wh/kg) for lightweight, portable devices.

Long cycle life, with up to 1,000 full charge cycles.

Low self-discharge rate, losing only 2–3% charge per month.

Stable voltage output and rapid charging.

Wide temperature tolerance for use in diverse environments.

The 18650 battery has earned trust in medical, robotics, security, infrastructure, and industrial sectors. You rely on its strong discharge capabilities and safety features to maintain Uninterrupted Life Support in critical applications.

2.3 NMC Chemistry for Safety and Performance

You choose NMC chemistry for its superior energy density and longevity. Compared to other lithium chemistries, NMC offers a higher energy density and longer cycle life. You see this chemistry used in medical devices, robotics, and infrastructure systems where reliability is essential.

Chemistry | Platform Voltage | Energy Density (Wh/kg) | Cycle Life (cycles) | Typical Applications |

|---|---|---|---|---|

LiFePO4 | 3.2V | 90–140 | 2,000+ | Medical, robotics, infrastructure |

NMC | 3.7V | 150–220 | 1,000–2,000 | Consumer electronics, industrial |

LCO | 3.6V | 150–200 | 500–1,000 | Consumer electronics |

LMO | 3.7V | 100–150 | 300–700 | Security, industrial |

Part3: Uninterrupted Life Support Design

3.1 Cell Quality and Assurance

You must select high-quality cells to build a reliable battery pack for portable ventilators. Cell selection and quality assurance play a critical role in the overall reliability of life-support systems. When you choose cells with proven performance and uniform characteristics, you reduce the risk of unexpected failures. Each cell in your pack must meet strict standards for capacity, voltage, and cycle life. If you use poor-quality cells, you may face serious problems such as sudden pack failure or reduced runtime. Even one faulty cell can compromise the entire battery pack, putting patient safety at risk.

Cell selection and quality assurance are vital for ensuring the reliability of battery packs in life-support applications.

Single-cell reliability directly influences the overall reliability of the battery pack.

Poor battery quality can lead to significant performance and safety issues, including complete pack failure due to a single cell’s malfunction.

Variability in cell energy and aging can result in underperformance compared to packs with uniform cells, affecting the pack’s ability to meet energy requirements.

You should work with suppliers who provide detailed test reports and traceability for every cell batch. This approach helps you maintain consistent performance and supports Uninterrupted Life Support in medical environments.

3.2 Battery Management System (BMS)

You rely on a robust Battery Management System (BMS) to keep your lithium battery packs safe and operational. The BMS monitors each cell, balances charge levels, and protects against overcharge, over-discharge, and short circuits. These features ensure your ventilator battery pack delivers continuous power without interruption.

Feature | Contribution to Operation and Safety |

|---|---|

Hot-swappable battery packs | Ensure continuous operation of ventilators without downtime. |

Compliance with safety standards | Prevents incidents like premature discharge, enhancing patient safety. |

Effective power management | Reduces risk of unexpected failures, ensuring reliable device performance. |

You benefit from hot-swappable battery packs, which allow you to replace batteries without stopping the ventilator. The BMS also helps you comply with medical safety standards, reducing the risk of premature discharge and device failure. Effective power management supports reliable operation in demanding environments, such as hospitals, ambulances, and field clinics. These features are essential for maintaining Uninterrupted Life Support.

3.3 Thermal and Physical Protection

You must protect your battery pack from heat, impact, and environmental hazards. Thermal management systems control temperature and prevent overheating, which can damage cells or cause safety issues. You use sensors and heat sinks to keep the battery within safe operating limits. Physical protection includes strong enclosures, shock-absorbing materials, and waterproof seals. These design elements shield your battery from drops, vibration, and moisture.

Thermal management prevents overheating and extends battery life.

Physical protection guards against impact, vibration, and environmental hazards.

Waterproof and dustproof enclosures support use in ambulances, field hospitals, and mobile clinics.

You should test your battery packs under real-world conditions to ensure they perform reliably in every scenario. By combining cell quality, advanced BMS, and robust protection, you create a battery pack that supports Uninterrupted Life Support for patients who depend on portable ventilators.

Part4: Compliance and Longevity

4.1 Medical Standards and CE Certification

You must meet strict international standards when you design lithium battery packs for portable ventilators. CE certification proves your battery complies with health, safety, and environmental rules in the European Economic Area. You need to prepare a Declaration of Conformity and keep technical documentation to show your battery meets EU directives. Test reports provide evidence of safety and reliability. The table below summarizes the main requirements:

Requirement | Description |

|---|---|

CE Certification | Ensures compliance with health, safety, and environmental standards in the EEA. |

Declaration of Conformity | A document proving compliance with EU directives. |

Technical Documentation | Required to demonstrate adherence to safety standards. |

Test Reports | Evidence of safety and reliability through important tests. |

If you do not comply, you risk product recalls, market bans, and legal penalties. These consequences can damage your reputation and cause financial loss. The table below shows possible regulatory risks:

Regulatory Risk | Impact on Business | Example Scenario |

|---|---|---|

Product Recall | Financial loss, reputation damage | Counterfeit batteries in medical devices |

Market Ban | Loss of access to global markets | Non-compliance with IEC or UN standards |

Legal Penalties | Fines, lawsuits | Device failures causing patient harm |

You should also consider sustainability and conflict minerals when sourcing cells. Learn more about responsible sourcing at Our Approach to Sustainability and Conflict Minerals Statement.

4.2 Testing and Validation

You need to test and validate every battery pack before deployment. Testing includes electrical performance, safety features, and environmental resistance. You should run cycle life tests and simulate real-world conditions. Validation ensures your battery meets medical device standards and performs reliably in hospitals, ambulances, and field clinics. You must keep detailed records of all test results for regulatory audits.

Tip: Use independent labs for critical safety and reliability tests to strengthen your compliance documentation.

4.3 Maintenance and Replacement

You extend battery life and reduce risk by following a strict maintenance schedule. You should check batteries monthly for cleanliness, secure connections, and system alerts. Every quarter, analyze performance data and compare it with previous years. Annually, conduct a full service, including all previous checks, and consider professional help. Always install batteries in stable environments, away from extreme temperature changes. The table below outlines best practices:

Frequency | Maintenance Task |

|---|---|

Monthly | Perform a visual check for cleanliness, secure connections, physical integrity, and system alerts. |

Quarterly | Analyze performance data and compare energy production and storage with previous years. |

Annually | Conduct a thorough service including all monthly and quarterly checks, possibly with professional help. |

Environmental | Install batteries in a stable environment, protected from extreme temperature fluctuations. |

You improve reliability and support patient safety by maintaining your lithium battery packs according to these guidelines.

Part5: Real-World Applications

5.1 Case Studies

You see the 14.8V 4S3P (18650) NMC battery pack powering portable ventilators in hospitals and ambulances. In one hospital, you use these battery packs to support ventilators during patient transport. The staff reports fewer interruptions and longer runtime compared to older battery packs. In robotics, you deploy similar battery packs in mobile medical robots that deliver supplies and monitor patients. Security teams rely on these packs for surveillance drones that need stable power and safe operation in crowded areas. Infrastructure companies use the same configuration for remote monitoring stations, where reliability and long cycle life matter most.

Sector | Application Scenario | Key Benefit |

|---|---|---|

Medical | Portable ventilators in ambulances | Extended runtime, safety |

Robotics | Mobile medical robots | Stable voltage, longevity |

Security | Surveillance drones | Safe operation, reliability |

Infrastructure | Remote monitoring stations | Long cycle life, durability |

Industrial | Portable diagnostic equipment | Consistent power output |

Tip: You improve device uptime and safety by choosing NMC chemistry for critical applications.

5.2 Lessons Learned

You learn several important lessons from real-world use. First, you must prioritize cell quality and traceability. Poor-quality cells lead to unexpected failures and shorter battery life. Second, you need a robust Battery Management System (BMS) to monitor and protect each cell. You see that regular maintenance and testing prevent most issues before they affect device performance. You also discover that NMC chemistry offers the best balance of safety and cycle life for medical and industrial devices.

Always verify cell batch reports and supplier certifications.

Schedule routine maintenance and performance checks.

Use NMC chemistry for applications that demand safety and longevity.

Implement BMS features like cell balancing and fault detection.

You support uninterrupted life support and device reliability by following these best practices. You help your organization meet regulatory standards and deliver safe, dependable solutions for every critical scenario.

You follow critical steps when designing a 14.8V 4S3P (18650) battery for portable ventilators. You select high-quality cells, use advanced battery management systems, and meet strict medical standards. Safety, reliability, and compliance guide every decision. You help deliver Uninterrupted Life Support by prioritizing careful engineering and ongoing maintenance. Your commitment protects patients and supports dependable medical devices.

FAQ

What makes NMC batteries safer for medical devices?

NMC batteries offer higher energy density and stable platform voltage. You gain enhanced safety and long cycle life, which supports critical applications in medical, robotics, and infrastructure sectors.

How does the 4S3P configuration benefit portable ventilators?

You get stable 14.8V output and scalable capacity. The 4S3P design supports long runtime and reliable power delivery, which is essential for medical and industrial devices.

Why should you choose 18650 cells for lithium battery packs?

You benefit from high energy density, compact size, and proven reliability. 18650 cells fit easily into ventilator housings and support applications in security, robotics, and industrial equipment.

How do lithium battery chemistries compare for life-support devices?

Chemistry | Platform Voltage | Energy Density (Wh/kg) | Cycle Life (cycles) | Typical Applications |

|---|---|---|---|---|

LiFePO4 | 3.2V | 90–140 | 2,000+ | Medical, robotics |

NMC | 3.7V | 150–220 | 1,000–2,000 | Industrial, consumer |

LCO | 3.6V | 150–200 | 500–1,000 | Consumer electronics |

LMO | 100–150 | 300–700 | Security, infrastructure |

What maintenance steps help extend lithium battery pack life?

Tip: You should inspect connections monthly, analyze performance quarterly, and schedule annual professional service. Regular maintenance ensures reliability for medical, robotics, and industrial applications.