You face a real challenge when designing wireless handheld medical devices. You must keep the battery light but still deliver enough runtime for demanding medical tasks. Every gram matters in advanced portable medical devices, and battery choice often shapes the entire device experience. Material science, battery chemistry, and smart device design all work together to boost both performance and safety. If you want real results, focus on practical power management and always select the right battery for your medical devices.

Key Takeaways

Advanced materials and nanotechnology can significantly enhance battery performance, allowing for lighter and more efficient designs in medical devices.

Selecting high-energy-density batteries is crucial for longer runtimes without adding weight, but safety and management complexity must also be considered.

Implementing effective power management schemes, such as low-power microcontrollers and energy harvesting, can extend the operational time of portable medical devices.

Regularly measuring battery runtime and maintaining optimal charge levels can prolong battery life and reduce unexpected device failures.

Choosing batteries that meet safety and regulatory standards ensures reliability and compliance in medical applications.

Part 1: Battery Technology in Wireless Handheld Medical Devices

1.1 Advanced Materials and Nanotechnology

You can achieve remarkable improvements in wireless handheld medical devices by using advanced materials and nanotechnology. These innovations help you increase battery performance, charging speed, and runtime. The latest breakthroughs in battery technology focus on nanoscale engineering, which allows you to store more energy in a smaller, lighter package.

Advancement Type | Description |

|---|---|

Silicon Nanowire Anodes | Utilizes nanosized silicon wires to enhance energy density and longevity in lithium-ion batteries. |

Lithium-Sulfur Batteries | Incorporates nanomaterials to improve energy density and address longevity issues. |

Solid-State Batteries | Replaces liquid electrolytes with solid materials, enhancing safety and energy density. |

Nanostructured Lithium Metal Anodes | Increases surface area for lithium-ion interaction, improving charge/discharge efficiency and safety. |

You can also benefit from innovations like carbon shell nanoparticles around silicon, which boost energy density and protect against electrolyte damage. Nanoengineered graphene aerogel improves sulfur utilization in lithium-sulfur batteries, making them more efficient for medical device battery applications. Researchers are exploring sodium-sulfur batteries as a cost-effective alternative with a longer life cycle. For more on the science behind these materials, you can read Nature’s coverage of battery nanotechnology.

Nanotechnology increases battery surface area by up to 1,000 times. This means you can store more energy in a smaller space, which is critical for portable medical devices. Charging times can drop to as little as 30 minutes, so your devices spend less time out of service. Nanochains and antimony-based anodes further increase lithium-ion storage and maintain stable capacity after many charging cycles.

Tip: Advanced nanomaterials not only improve energy density and capacity but also extend the lifespan of lithium-ion batteries, reducing replacement frequency in medical settings.

1.2 High-Energy-Density Solutions

Selecting high-energy-density solutions is essential for wireless handheld medical devices. You want batteries that deliver long runtimes without adding unnecessary weight. The table below compares the energy density of common battery types:

Battery Type | Energy Density (Wh/kg) | Comparison |

|---|---|---|

Sodium Sulfur Battery | Three times greater than lead-acid battery | |

Lead-Acid Battery | 253 | Three times less than sodium sulfur battery |

High-energy-density batteries give you longer usage times and lighter devices. However, you must consider safety and management complexity. Lithium-ion batteries offer high energy density and are widely used in medical, robotics, security systems, and consumer electronics. Lithium Iron Phosphate (LiFePO4) batteries, while heavier, provide excellent safety and longevity, making them suitable for critical medical applications.

High-energy-density batteries provide longer usage times and lighter devices but may pose safety concerns and require complex management systems.

Lithium Iron Phosphate (LiFePO4) batteries, while heavier, offer excellent safety and longevity, making them suitable for medical applications.

The trade-off involves balancing the need for lightweight designs against the performance and safety characteristics of different battery chemistries.

Note: Always balance energy density and capacity with safety and reliability, especially in medical environments.

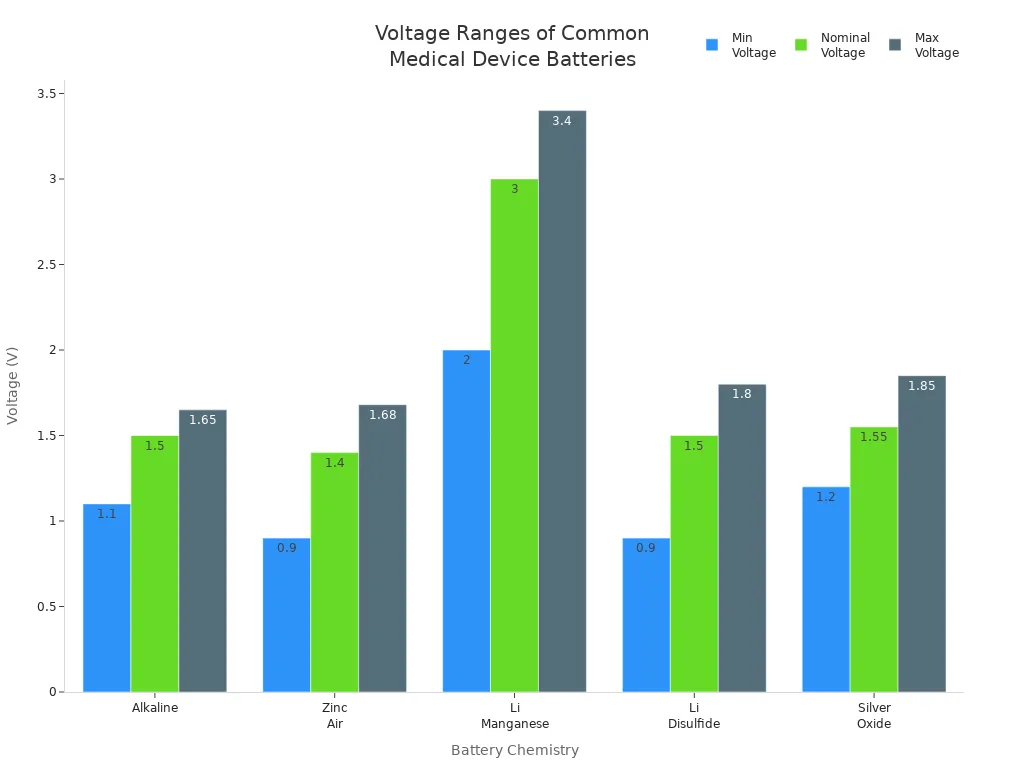

1.3 Battery Chemistry and Voltage Regulation

Choosing the right battery chemistry and voltage regulation system is crucial for medical device battery performance. The table below shows typical voltage ranges for common chemistries used in wireless handheld medical devices:

Battery Chemistry | Min Voltage | Nominal Voltage | Max Voltage |

|---|---|---|---|

Alkaline | 1.1 V | 1.5 V | 1.65 V |

Zinc Air | 0.9 V | 1.4 V | 1.68 V |

Li Manganese | 2 V | 3 V | 3.4 V |

Li Disulfide | 0.9 V | 1.5 V | 1.8 V |

Silver Oxide | 1.2 V | 1.55 V | 1.85 V |

LiFeS2 | N/A | 1.5 V | N/A |

LiMnO2 | N/A | 3 V | N/A |

Zinc Air | 0.9 V | 1.4 V | N/A |

You must ensure correct voltage regulation to maintain stable operation and reduce the risk of device failure. Poor power supply quality can cause medical equipment to crash, leading to data loss and component damage. Voltage regulators protect sensitive equipment from fluctuations and help you comply with safety regulations. For advanced battery management, you should consider integrating a battery management system (BMS).

Below is a comparison of lithium battery chemistries, their platform voltage, energy density, and cycle life, along with typical application scenarios:

Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) | Application Scenarios |

|---|---|---|---|---|

LiFePO4 | 3.2 | 90-140 | 2000-7000 | Medical, industrial, robotics, infrastructure |

NMC | 3.7 | 150-220 | 1000-2000 | Medical, consumer electronics, security systems |

LCO | 3.7 | 150-200 | 500-1000 | Consumer electronics, medical |

LMO | 3.7 | 100-150 | 300-700 | Medical, industrial, robotics |

LTO | 2.3 | 70-80 | 7000-20000 | Industrial, infrastructure, robotics |

Solid-State | 3.7-4.2 | 250-500 | 1000-5000 | Medical, robotics, security systems |

Lithium Metal | 3.7-4.2 | 350-500 | 500-1000 | Medical, security systems, industrial |

Alert: Always match your battery chemistry and voltage regulation to your device’s requirements to ensure safety, reliability, and compliance in medical devices.

Part 2: Optimizing Runtime and Battery Weight

2.1 Power Management Schemes

You can significantly improve the runtime of portable medical devices by adopting advanced power management schemes. Low-power microcontrollers play a key role in this process. These microcontrollers offer multiple sleep modes and can shut down peripheral subsystems when not in use. By allowing the CPU to enter deep sleep, you minimize high-power states and extend the operational time of your wireless handheld medical devices.

Many portable medical devices, such as WiFi blood pressure monitors and wearable patient monitors, rely on Bluetooth Low Energy (BLE) radios. BLE radios consume very little power while maintaining reliable connections. This makes them ideal for continuous health monitoring applications, where uninterrupted data transmission is critical.

You can also explore energy harvesting techniques to supplement or even replace traditional battery power. Piezoelectric energy harvesters and thermoelectric generators capture ambient energy from movement or temperature differences. These methods can extend device operation and reduce the frequency of battery replacements, which is especially valuable in clinical environments.

The SmartAPM framework uses deep reinforcement learning to optimize power consumption based on user behavior. This system dynamically adjusts device settings, which leads to longer battery life and a better user experience. SmartAPM has proven effective in wearable medical devices by reducing the need for frequent charging cycles.

Tip: Integrate a battery management system (BMS) to monitor and control power usage. This helps prevent overcharging or overdischarging, which can damage lithium battery packs and compromise device safety.

2.2 Measuring and Extending Runtime

Accurately measuring battery runtime is essential for ensuring reliable operation in portable medical devices. You have several methods available:

Method | Description |

|---|---|

Battery Simulators | Simulate battery conditions dynamically over the entire discharge cycle, allowing for realistic testing. |

Precision Power Supplies | Provide stable power to test devices under various load conditions, ensuring accurate runtime measurements. |

Actual Battery Testing | Use a real battery to measure runtime, though this method can be time-consuming and less precise. |

Advanced power management techniques also improve the accuracy of state of charge (SOC) and state of health (SOH) calculations. Accurate SOC and SOH readings help you avoid overcharging or overdischarging, which extends battery lifetimes and reduces risks such as short circuits or fires. This leads to more efficient energy use in portable medical devices.

Rechargeable lithium-ion batteries support device miniaturization and provide excellent charge cycling. This prolongs the overall system life and reduces the need for frequent maintenance. Adequate rechargeable batteries prevent unnecessary interventions, which is especially important in medical and industrial settings.

Impact Description | Quantitative Measure |

|---|---|

Battery lifetime extension | From 10 years to 20 years |

General lifetime improvement | 30 percent |

Reduction in total cost of ownership | Greater than 30 percent |

You can see these benefits in devices like wearable patient monitors, which require long runtime and minimal downtime. By using lithium battery packs with advanced management systems, you ensure that your portable medical devices remain operational and reliable.

2.3 Removable and Modular Battery Options

Removable and modular battery systems offer significant advantages for portable medical devices. You can replace individual battery modules without shutting down the entire system. This feature minimizes downtime and ensures continuous operation, which is critical in clinical environments.

Modular battery systems also reduce long-term maintenance costs. The presence of a battery management system (BMS) means you need minimal active maintenance. The BMS monitors essential parameters, ensuring safe operation and extending the life of your lithium battery packs.

Note: Modular battery options improve user convenience and device uptime, making them ideal for portable medical devices in hospitals, clinics, and field settings.

When you select the right battery system for your wireless handheld medical devices, you optimize both weight and runtime. This approach supports high performance in medical, robotics, security systems, and industrial applications. By focusing on power management, accurate runtime measurement, and modular battery design, you create portable solutions that meet the demands of modern healthcare and technology environments.

Part 3: Medical Device Battery Selection

3.1 Safety and Regulatory Standards

When you select a medical device battery for wireless handheld medical devices, you must prioritize safety and regulatory compliance. International standards like IEC 62133 and UN 38.3 set strict requirements for battery technology in medical devices. These standards ensure that each battery passes tests for overcharge, short circuit, vibration, and temperature cycling. The table below outlines the most important standards and their key tests:

Standard | Description | Key Tests Included |

|---|---|---|

IEC 62133 | International standard for safety of rechargeable batteries. | Overcharge & Forced Discharge, External Short Circuit, Vibration & Mechanical Shock, Temperature Cycling, Molded Case Stress Test |

UN 38.3 | Mandatory for safe transport of lithium batteries. | Altitude Simulation, Thermal Test, Vibration, Shock, External Short Circuit, Impact/Crush, Overcharge, Forced Discharge |

You must also consider regulatory influences that impact battery selection. Regulatory bodies require batteries to meet high standards for performance, reliability, and safety. Testing often goes beyond standard specifications to address the unique risks of medical applications. In the EU, regulations require that batteries be removable and replaceable by end users, which affects both design and selection.

Tip: Always verify that your medical grade battery supplier meets all relevant international and regional standards.

3.2 Temperature and Environmental Considerations

Environmental conditions can affect the reliability and safety of your medical device battery. You should select battery technology that performs well under temperature extremes and humidity. Nickel-metal hydride batteries tolerate high temperatures and offer cost-effective solutions for portable medical equipment. The FDA and IEC standards require rigorous testing to ensure battery reliability in diverse healthcare environments.

Evidence Type | Description |

|---|---|

Battery Type Selection | Nickel-metal Hydride batteries are robust, cost-effective, and tolerant to high temperatures, making them suitable for varying environmental conditions in medical devices. |

Regulatory Compliance | The FDA mandates rigorous testing and quality assurance for battery safety and reliability in medical devices. |

International Standards | IEC standards provide global benchmarks for battery performance and safety, ensuring reliability in diverse healthcare environments. |

You should monitor temperature and humidity to prevent corrosion and capacity loss. For lithium-ion batteries, ideal operating temperatures range from 20–25°C. High humidity can cause corrosion, so routine inspections are essential.

3.3 Performance Metrics and Longevity

You need to evaluate key performance metrics when choosing the best battery for medical devices. Focus on average lifespan, cycle life, and rechargeability. Lithium-ion batteries, especially LiFePO4, offer 2000+ cycles and reduce replacement frequency by 50% over two years. This makes them ideal for portable medical equipment and wireless charging applications.

Battery Type | Cycle Life | Replacement Frequency |

|---|---|---|

NMC | ~1000 cycles | Higher frequency due to shorter lifespan |

LiFePO4 | 2000+ cycles | 50% reduction in replacements over 2 years |

To maximize rechargeability and longevity, keep the charge between 20–80% and avoid deep discharges. Regular trickle charging and using manufacturer-recommended chargers extend battery life. Hospitals that use smart chargers report up to 15% longer battery life for infusion pumps. Routine maintenance, such as capacity testing and visual inspections, helps you identify degradation early.

Proactive battery replacement can reduce unexpected device failures by 37% and minimize downtime in medical devices.

Part 4: Portable Medical Devices: Design Optimization

4.1 Ergonomics and Weight Distribution

You improve the performance and user experience of wireless handheld medical devices by focusing on ergonomic design and proper weight distribution. Ergonomics aligns the device with the natural movements of users, enhancing comfort and reducing fatigue. When you design control surfaces to fit the natural landing of fingertips, you allow for better manipulation and dexterity. Devices that accommodate both left and right-handed users ensure balanced use and comfort for all staff. Indents and curves tailored to finger size and grip promote ease of use and reduce strain. You also minimize the risk of injury by distributing weight evenly, which is essential for portable medical devices used in fast-paced clinical environments.

Ergonomic design improves efficiency and productivity.

Proper weight distribution reduces physical strain and injury risk.

User-friendly devices contribute to better patient outcomes and recovery.

Balanced design enhances working conditions for medical staff.

4.2 Thermal Management

You maintain battery safety and reliability in portable medical devices by implementing effective thermal management techniques. Advanced cooling systems balance cooling efficiency with power consumption, preventing battery drain. Temperature monitoring and thermal runaway prevention keep lithium-ion batteries operating within safe limits. You use liquid cooling and heat sinks to manage heat produced during battery operation, which extends battery life and improves device performance. Comprehensive safety mechanisms, such as fault detection systems, monitor for failures and thermal runaway, allowing for early intervention. Uniform temperature distribution across battery cells enhances both safety and reliability, which is critical for medical device battery packs in clinical and industrial settings.

Advanced cooling systems

Temperature monitoring

Thermal runaway prevention techniques

4.3 Integration of Battery Technology

You optimize portable medical devices by integrating battery technology directly into the device architecture. Advanced lithium-ion batteries allow you to create compact, lightweight designs that meet strict space limitations. You select battery technology that supports long-lasting power for devices such as wearable health monitors and implantable pacemakers. Customizing battery size and weight to fit device contours maximizes capacity and maintains biocompatibility. You choose low-power microcontrollers to enhance battery efficiency and extend runtime. Higher density batteries improve performance in compact devices, supporting applications in medical, robotics, security systems, and industrial sectors.

Design Consideration | Description |

|---|---|

Battery Life | Critical for disposable devices, especially those with RF communication or displays. |

Low-Power Microcontrollers | Advances in technology can enhance battery efficiency. |

Higher Density Batteries | New battery technologies improve performance in compact devices. |

Wi-Fi connectivity can increase battery consumption, making it less suitable for portable medical devices that require frequent recharging. You prioritize medical grade battery solutions that deliver reliability, safety, and long-term performance.

Tip: Integrating advanced lithium-ion battery technology supports lightweight design, maximizes battery life, and enhances the reliability of portable medical devices.

You can optimize battery weight and runtime in wireless handheld medical devices by combining advanced battery technology, smart power management, and thoughtful design. The best battery for medical devices uses features like BLE 5.0, low power activation, and optimized transmit power to reduce energy use and improve device comfort. Portable medical devices benefit from solid-state batteries and ultrasound wireless charging, which increase safety and convenience. You should follow a checklist for medical device battery selection:

Choose suppliers dedicated to medical battery manufacturing.

Use original specifications for each medical device battery pack.

Verify supplier track record and conduct 100% testing.

Confirm FDA compliance and inspect facilities.

Align battery use protocols with replacement schedules.

Ongoing innovation in portable medical devices, such as improved PMICs and sustainable battery technologies, supports reliable performance in medical, robotics, and industrial sectors. You drive progress by adapting to new battery advancements.

FAQ

What factors should you consider when selecting a lithium battery pack for medical devices?

You should evaluate energy density, cycle life, platform voltage, and safety standards. Always match the battery chemistry to your device’s power needs. Consider application scenarios in medical, robotics, security systems, and industrial sectors.

How do lithium battery chemistries impact device performance?

Different chemistries, such as LiFePO4 or NMC, offer unique platform voltages and cycle lives. For example, LiFePO4 provides 3.2V and 2000–7000 cycles. Choose the chemistry that best fits your device’s runtime and safety requirements.

Why is a battery management system (BMS) important in wireless handheld medical devices?

A BMS monitors and controls charging, discharging, and temperature. You prevent overcharging and extend battery life. This system ensures safe operation in critical environments like hospitals, robotics, and security systems.

Can you use modular lithium battery packs in portable medical devices?

Yes. Modular packs allow you to replace individual modules without shutting down the device. This design reduces downtime and maintenance costs in medical, industrial, and infrastructure applications.

How does temperature affect lithium battery pack performance?

High or low temperatures can reduce battery efficiency and lifespan. You should keep lithium battery packs within recommended temperature ranges, especially in medical and industrial environments, to maintain safety and performance.