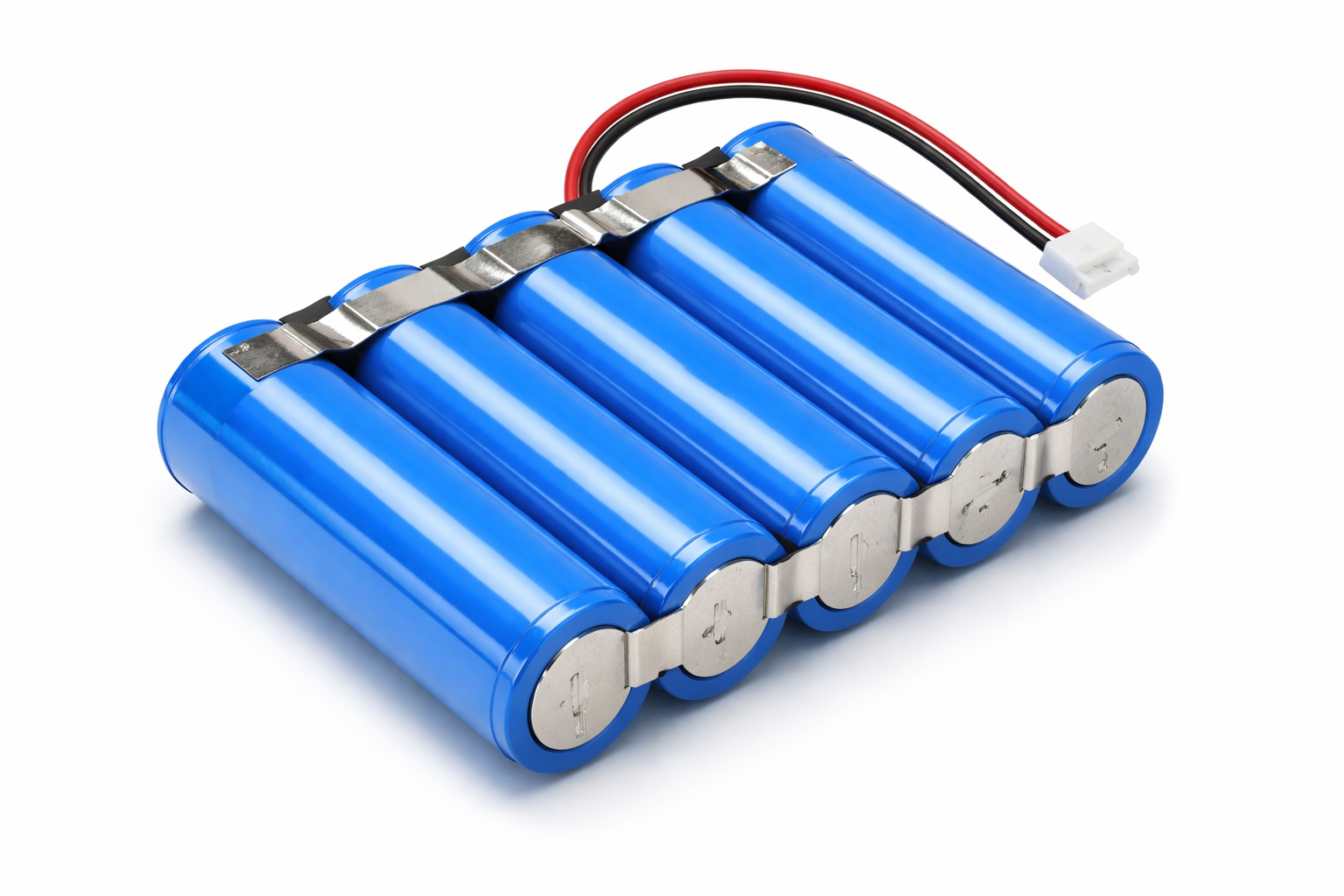

Cylindrical Lithium-ion Battery(INR18650EX-3350mAh)

The battery cell shall be free from noticeable defects such as scratches, burrs, dents, or any other mechanical damage.

The exposed metal terminals shall be free from rust and contamination.

| Item | Specifications | Remarks |

|---|---|---|

| Nominal Capacity | 3350 mAh | Standard discharge at 0.2C |

| Rated Capacity | 3250 mAh | — |

| Nominal Voltage | 3.6 V | Average operating voltage |

| Delivery Voltage | 3.5 – 3.7 V | Within 10 days after shipment |

| Charge Ceiling Voltage | 4.2 V | Standard charge method |

| Discharge Cut-off Voltage | 2.5 V | — |

| Internal Impedance | ≤ 60 mΩ | AC 1 kHz measurement at 50% SOC |

| Charge Current | Standard: 0.2C (0~45°C) Maximum: 0.5C (10~45°C) | Based on recommended charging profile |

| Discharge Current | Standard: 0.2C (-20~60°C) Max. continuous: 4.875A (0~40°C) | — |

| Storage Temperature | < 1 month: -10~45°C < 3 months: -10~35°C < 6 months: 0~25°C | Recommended: 65±25% RH |

| Charging Operating Temp. | 0~45°C | — |

| Discharging Operating Temp. | -20~60°C | — |

| Weight | Approx. 47.0 g | — |

Appearance

The battery cell shall be free from noticeable defects such as scratches, burrs, dents, or any other mechanical damage.

The exposed metal terminals shall be free from rust and contamination.

Test Equipment

Dimension Measuring Instrument

The accuracy for dimension measurement instruments shall be no less than 0.01 mm.

Voltmeter

Compliant with national standards or higher sensitivity level, with internal impedance ≥ 10 kΩ/V.

Ammeter

Compliant with national standards or higher sensitivity level.

The total external resistance including the ammeter and wires shall be < 0.01 Ω.

Impedance Meter

Internal impedance shall be measured using an AC impedance method (AC 1 kHz LCR meter).

Standard Test Conditions

-

Tests shall be conducted on new batteries within one month of shipment from the factory.

-

Batteries shall not be cycled more than five times before testing.

-

Unless otherwise specified, testing shall be performed under the following environmental conditions:

| Parameter | Specification |

|---|---|

| Temperature | 25 ± 5°C |

| Relative Humidity | 65 ± 25% |

Cell Performance & Reliability Test

| Item | Test Method | Criteria |

|---|---|---|

| Standard Charge | Charge the cell at 0.2C constant current to 4.2V at 25±2°C, then switch to constant voltage of 4.2V until the current drops below 0.02C. Charging time is approximately 6 hours. | — |

| Temperature Discharge Performance | • After standard charge, store at -10±2°C for 4 hours, then discharge at 0.2C to 2.5V. • At 25°C, discharge at 0.2C constant current to 2.5V. • After standard charge, store at 55±2°C for 2 hours, then discharge at 0.2C to 2.5V. | ≥70% at -10°C ≥100% at 25°C ≥95% at 55°C |

| Storage Performance @ 25°C | After standard charge, store at 25±3°C for 28 days, then discharge at 0.2C to 2.5V to measure remaining capacity. Recharge and discharge again at 0.2C to measure recovery capacity. | Remaining Capacity ≥ 90% Recovery Capacity ≥ 95% |

| Cycle Life @ 25°C | Charge at 0.5C CC to 4.2V, then CV to 0.02C → rest 5 min → discharge at 1.0C to 2.5V → rest 5 min. Repeat for 300 cycles continuously. | ≥63% of nominal capacity after 300 cycles |

| Long-term Storage | Charge the cell to 40–45% SOC (standard method), store at 20±5°C and 45–75% RH for 12 months. Then perform 5 charge/discharge cycles at 0.2C. Capacity is measured after recovery. | Capacity retention ≥ 80% |

Environmental adaptability

| No. | Item | Test Method | Criteria |

|---|---|---|---|

| 1 | Constant Temperature & Humidity Test | After standard charge, place the cell in a chamber at 40±2°C and 90–95% RH for 48 hours. Then store at 23±2°C for 2 hours. Visually inspect and discharge at 0.2C to the cut-off voltage. | No deformation, no rust, no leakage, no venting, no rupture, no fire, no explosion. Discharge capacity ≥ 60%. |

| 2 | Drop Test | After standard charging, rest for 1–4 hours. Drop the cell from a height of 1.5 m onto a concrete floor. Each face is impacted once, 6 drops in total. | No fire and no explosion. |

| 3 | Vibration Test | Fully charged cell is subjected to a sinusoidal vibration with 0.8 mm amplitude (1.6 mm max. total excursion). Frequency varies from 10 Hz to 55 Hz at 1 Hz/min and returns within 90–100 min. Test along three perpendicular axes. | No leakage, no venting, no rupture, no fire, no explosion. |

| 4 | Temperature Cycling Test | Fully charged cell undergoes: • 75±2°C for 6 h → change ≤30 min → -40±2°C for 6 h → change ≤30 min → repeat 10 cycles. After cycling, store at room temperature for ≥2 h before inspection. | No leakage, no venting, no rupture, no fire, no explosion. |