A Premier Custom Battery Designer & Battery Pack Manufacturer

Why Choose Large Power as Your Custom Battery Pack Manufacturer?

- Strong Custom Battery Manufacturing Capacity

Our state-of-the-art, ISO 9001-certified facilities are equipped for both rapid prototyping and high-volume production runs. We implement rigorous quality control at every stage, from cell sourcing to final assembly, ensuring every custom battery we produce meets the highest standards of quality and consistency. - High Technologies with Proven Records

We thrive on solving the toughest power challenges. Our engineering team has a proven track record of developing innovative custom power solutions for the most demanding environments. Our expertise includes:- Custom Low-Temperature Batteries:Delivering reliable power in freezing conditions.

- Custom High-Temperature Batteries:Ensuring safety and performance in extreme heat.

- Custom Explosion-Proof Batteries:Providing IECEx-certified power for hazardous locations.

- Custom Semi-Solid State Batteries:Pushing the boundaries of energy density and safety.

- A Collaborative Engineering Partnership

We work as an extension of your team. Our engineers collaborate with you from the initial design phase to understand your device’s unique power profile, mechanical constraints, and performance goals. This partnership ensures the final customized battery is perfectly optimized for your application. - Resilient and Reliable Supply Chain

We mitigate supply chain risks by building strong, long-standing relationships with the world’s leading Tier-1 cell manufacturers, including Panasonic, Samsung, LG, and Saft. Our robust supply chain management ensures access to authentic, high-quality components, providing the stability and predictability your production schedule demands.

Custom Battery Pack by Chemistry: Designed for Your Specific Needs

The core of every great battery pack is its chemistry. We are a technology-agnostic custom battery manufacturer, allowing us to select and engineer the ideal chemistry to meet the specific performance, safety, and cost requirements of your device.

Custom Lithium-Ion Battery Packs

Our lithium-ion (NMC/NCA) batteries offer high energy density, lightweight design, and smart BMS integration for safety and accurate fuel gauging—ideal for medical devices, drones, laptops, and other performance-driven portable electronics.

Custom Lithium Polymer (LiPo) Battery Packs

Our LiPo batteries are engineered for maximum design flexibility, featuring ultra-thin, lightweight, and custom-shaped cells that fit tight spaces and unique device profiles—perfect for wearables, AR/VR headsets, IoT sensors, and slim electronics.

Custom LiFePO4 Battery Packs

Our LiFePO4 batteries offer outstanding safety, thermal stability, and long cycle life—over 2,000+ cycles—making them ideal for medical carts, robotics, backup power, and electric vehicles where long-term reliability and lower TCO matter most.

Custom Battery Pack by Shape

The physical form of your battery is as critical as its chemistry. We engineer packs in both standard and fully custom shapes to ensure perfect mechanical integration and optimal space utilization.

Custom 18650 Battery Pack

The 18650 cylindrical cell offers high reliability, strong thermal performance, and durability. By configuring cells in series and parallel, we deliver custom 18650 battery packs tailored to your exact voltage and capacity needs—ideal for robust, cost-effective power solutions.

Custom Pouch Shape Pack

Our custom pouch cell packs break the limits of rectangular designs, enabling curved, L-shaped, circular, or ultra-thin batteries that fit seamlessly into innovative, space-constrained, and ergonomic products using flexible LiPo technology.

Our Custom Battery Assembly and Design Process

Our end-to-end process is designed for transparency, collaboration, and quality, ensuring we deliver a custom battery pack that meets your exact specifications and de-risks your project from start to finish.

Supply Chain Management & Cell Selection:

1.The process begins with quality. We source cells exclusively from audited, Tier-1 global manufacturers and conduct our own rigorous in-house qualification to ensure performance and reliability.

Custom Battery Design:

Our engineers collaborate with your team to define all electrical and mechanical requirements, using advanced 3D modeling to optimize for form factor, thermal management, and structural integrity.

Custom Battery Management System (BMS):

3.We design and integrate a smart BMS to ensure safety, maximize performance, and extend the pack's lifespan. This includes precision fuel gauging, cell balancing, and communication protocols for seamless integration with your device.

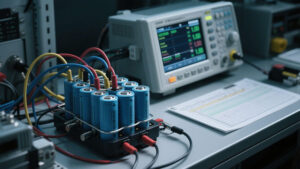

Custom Battery Assembly & Manufacturing:

4.In our ISO 9001-certified facilities, our skilled technicians use advanced techniques like laser welding and automated processes to assemble your custom battery packs with the highest level of precision and quality control.

In-House Testing & Certification:

5. Every battery pack undergoes 100% end-of-line functional testing. We also manage the entire global certification process, ensuring your pack meets all necessary standards, including UL, IEC, and UN 38.3, for market access.

Custom Battery Packaging:

6.We design and implement robust packaging solutions to ensure your custom battery packs are protected and arrive safely, ready for integration into your production line.

Why Partner with Large Power?

Management System

Certification

OEM/ODM Services for Custom Battery Packs

Whether you have a complete design ready for production or need a full-service partner to develop a power solution from the ground up, Large Power has you covered. We offer comprehensive OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services, providing the flexibility to meet your specific business needs and product development strategies.

Markets We Serve

Our expertise as a custom battery pack manufacturer is validated by our success in powering devices for the world’s most demanding industries.

Medical Equipment:

Delivering mission-critical reliability and safety for devices from portable patient monitors to surgical power tools.

Industrial Applications:

Engineering rugged, durable power solutions for industrial IoT, robotics, and backup power systems.

Defense and Aerospace:

Providing high-performance batteries that operate flawlessly in the most extreme and challenging environments.

Consumer Electronics:

Powering the next generation of innovative, high-performance consumer devices with optimized, compact batteries.

What Our Customers Say

Relevant Guidelines

Development timelines represent a critical design parameter when selecting between .custom lithium ion battery packs and off-the-shelf solutions. Standard battery packs achieve […]

Custom Battery Solutions for Specialized Applications Custom battery pack manufacturing involves a collaborative design process with our team and […]

In the ever-evolving landscape of technology, the demand for reliable, efficient, and custom battery solutions has never been higher. Custom […]

In today’s technology-driven world, understanding the various types of battery packs available is crucial for making informed decisions. Whether you’re […]

Frequently Asked Questions (FAQ)

In custom battery pack design, precise voltage, capacity, and current requirements must be met to ensure both performance and safety. Different applications may require complex configurations or specific voltage outputs.

An integrated Battery Management System (BMS) provides real-time monitoring, overcharge/over-discharge protection, thermal management, and cell balancing.

At the same time, enhanced thermal design and mechanical structure are required to withstand harsh environments such as extreme temperatures, vibration, and shock.

OEM/ODM battery manufacturers such as Large Power provide strong scalability for multi-battery certification projects, including:

-

ISO 9001 certified facilities covering the full process from prototyping to mass production.

-

Full management of global certifications such as UL, IEC, and UN 38.3.

-

Tier-1 level cell supplier network to ensure stable supply chains.

-

Flexible low MOQ support, making it easy to transition from prototype validation to volume manufacturing.

Engineers integrate international requirements during the design stage to ensure structure, materials, and electrical performance meet UL, IEC, and UN 38.3 standards.

All battery packs undergo 100% functional testing before shipment, combined with BMS safety features and mechanical protection to enhance reliability.

With ISO 9001 quality systems, automated production, and precision laser welding, manufacturers can guarantee consistent performance and global compliance.

-

Performance optimization: Achieves higher energy density, extended runtime, and optimal operating performance.

-

Enhanced safety: BMS protection, anti-shock design, explosion-proof features, and thermal management.

-

Tailored design: Fits unique form factors, limited spaces, or irregular structures.

-

Flexible production: Supports everything from prototype to large-scale production with fast turnaround and adaptable MOQs.

-

Consultation – Customers provide requirements such as voltage, capacity, dimensions, and operating environment.

-

Prototype development – Engineering team designs and tests prototypes, typically within 6–12 weeks.

-

Certification – Testing and certification according to UL, CE, IEC, and UN 38.3 standards.

-

Mass production & delivery – ISO 9001 factories carry out scalable production with full quality control for consistent results.