Development timelines represent a critical design parameter when selecting between .custom lithium ion battery packs and off-the-shelf solutions. Standard battery packs achieve production readiness within 4 weeks, while custom designs require 8-12 weeks for the design phase alone. This timeline differential significantly impacts project schedules and market entry strategies.

Battery pack specification involves multiple technical considerations beyond development duration. Custom solutions demand precise voltage requirements based on individual cell power output characteristics for the target application. Certification testing extends development periods by an additional 4 to 12 weeks depending on the certifying organization. Standard packs provide immediate deployment advantages and reduced initial costs, however customized battery packs deliver application-specific performance optimization that often justifies the extended timeline and higher lithium ion battery pack price.

The selection process requires balancing immediate availability against performance optimization. Engineers must evaluate both immediate project constraints and long-term product requirements. The technical considerations outlined in this guide will help determine the most appropriate approach for specific applications.

Defining Standard vs Custom Lithium-Ion Battery Packs

Image Source: Epec Engineered Technologies

Battery pack classification establishes the foundation for power system design decisions. The technical distinction between standard and custom lithium-ion battery packs determines development approach, component selection, and application performance characteristics.

What qualifies as a standard battery pack?

Standard battery packs consist of pre-engineered power solutions manufactured to common industry specifications. These configurations typically provide fixed voltage ratings of 3.6V, 7.2V, 12V, or 24V, with predetermined capacities specified in milliampere-hours (mAh) or ampere-hours (Ah). Standard battery packs utilize established cell arrangements and standardized protection circuits designed for broad compatibility across multiple device types.

Standard battery packs are not necessarily inventory items awaiting shipment. Manufacturers develop (BMS) modules that can be rapidly configured for different applications. This approach reduces development time while requiring limited design and assembly work, resulting in minimal non-recurring engineering charges.battery management system

Standard configurations include basic safety protection circuits for overcurrent and overvoltage conditions. These packs often incorporate existing certifications for safety standard compliance, though certification processes still add time and cost to development cycles.

What makes a battery pack ‘custom’?

Custom lithium ion battery packs are application-specific power sources engineered to meet precise device requirements. These specialized assemblies utilize carefully selected components configured to deliver optimal performance for specific operational parameters.

Customization encompasses multiple technical aspects:

- Voltage and capacity specifications matched to exact application demands

- Form factor optimization for available device space

- Cell chemistry selection based on performance and environmental requirements

- Application-specific safety features for operating conditions

- Battery management systems programmed for unique discharge characteristics

Custom lithium-ion battery pack designs eliminate inefficiencies through component-level optimization, maximizing energy density and extending operational life. Each element is selected and configured to prevent cells from operating outside their optimal performance range.

Why this distinction matters for engineers

The selection between standard and custom solutions presents fundamental engineering tradeoffs. Custom battery packs provide performance alignment with specific power requirements, optimizing efficiency and ensuring devices operate within design parameters. Custom designs enable superior space utilization, supporting more compact product architectures.

can develop packs meeting stringent quality specifications, ensuring reliability and durability while reducing maintenance requirements. Custom lithium-ion battery pack approaches enable engineers to address specific safety requirements through tailored protection mechanisms appropriate for particular operating environments.Custom lithium ion battery manufacturers

While initial lithium ion battery pack price is higher for custom solutions, optimized performance and reduced replacement frequency often provide superior long-term value. The customized battery pack approach allows engineers to incorporate protection mechanisms specifically relevant to their application environment.

Engineers must evaluate whether application-specific power requirements, space constraints, and performance expectations justify the additional development time and costs associated with custom battery pack design. This decision affects both immediate project parameters and long-term product performance.

Battery Management Systems: Basic vs Advanced Capabilities

Image Source: Bacancy Systems

Battery Management Systems (BMS) represent the electronic control center for lithium-ion battery pack operation. The protection circuits are contained in what is commonly referred to as the protection circuit module (PCM), which manages the electronics of a rechargeable battery pack by monitoring its state, reporting data, balancing cells, and protecting the battery while controlling its environment.

BMS in Standard Packs: Limited Control and Diagnostics

Standard battery packs incorporate basic BMS functionality designed primarily for essential protection rather than performance optimization. These systems provide fundamental safeguards with limited monitoring capabilities. Off-the-shelf BMS solutions generally offer standard protection functions only, focused on preventing catastrophic failures.

Most standard BMS are tailored for specific applications like electric vehicles or grid-tied systems, which limits their versatility. Many are restricted to working with certain battery chemistries and cell configurations. Basic diagnostic capabilities mean limited data for troubleshooting, with some utilizing simple analog technologies rather than programmable digital systems.

Custom BMS: Real-Time Monitoring and Programmable Profiles

Custom Battery Management Systems deliver enhanced intelligence and control through constant monitoring of key operational parameters during charging and discharging using outputs from sensors which give the actual status of voltages, currents, and temperatures within the battery as well as the state of charge.

Advanced systems track individual cell voltages in real-time, enabling precise —critical for maximizing usable capacity throughout the battery lifecycle. These systems provide sophisticated functionality including:cell balancing

- State of Charge (SOC) calculations for immediate power level information

- State of Health (SOH) measurements indicating storage and delivery capabilities

- Active or passive balancing techniques to equalize voltage across cells

- Programmable parameters for application-specific optimization

High-end custom lithium ion battery packs often include BMS that support CAN, I2C, or SMBus protocols for seamless integration with existing systems. Some advanced systems transmit data to cloud platforms for comprehensive analysis, enabling predictive maintenance.

Safety Features: Overcharge, Temperature, and Fault Detection

The primary safety circuits manage all the basic safety functions: over-voltage, under-voltage, over-current, and sometimes over- and under-temperature. Basic protection includes overcurrent blocking, under-voltage prevention, and short circuit protection. However, custom battery pack designs incorporate more comprehensive safety systems with multiple layers of protection.

Advanced BMS continuously monitor for faults including over-voltage, under-voltage, short circuits, and thermal issues, triggering protective actions like shutdowns or alarms. Temperature management is particularly vital—custom systems use sensors to monitor temperatures and algorithms to prevent overheating by adjusting performance. Besides preventing , custom BMS can inhibit charging outside safe temperature ranges.thermal runaway

For applications requiring highest reliability, premium customized battery packs may incorporate secondary safety circuits that activate if primary protection fails, a critical feature for medical or industrial environments where failure is not an option.

Performance and Design Flexibility

Physical design characteristics and performance parameters directly influence battery pack effectiveness in real-world applications. Engineers must address critical decisions regarding , physical configuration, and application-specific optimization when selecting appropriate energy solutions.power delivery

Power Output and Runtime Optimization

Power requirements differ substantially across device types, making optimization essential for efficient operation. Custom lithium ion battery packs enable precise voltage and capacity configurations through specific cell arrangements. Series connections increase voltage while parallel configurations boost capacity and runtime. A 2s2p configuration doubles capacity compared to a 1s1p arrangement, extending runtime under identical power loads.

Battery chemistry selection significantly affects performance capabilities. Custom lithium ion battery manufacturers can incorporate like silicon anodes that deliver increased capacity compared to traditional graphite anodes. This material selection process allows for annual energy density improvements of 5-8% in custom designs.advanced materials

Form Factor and Enclosure Customization

Standard battery packs force designers to compromise on ergonomics or capacity. Custom solutions can be molded into curved, L-shaped, trapezoidal, or ultra-thin configurations, maximizing available internal volume. This optimized assembly can deliver a 15-25% increase in capacity within the same form factor.

Enclosure materials present additional customization opportunities. Traditional options include steel for durability and aluminum for lightweight strength, however newer alternatives like thermoplastics and glass fiber polypropylene reduce weight while maintaining thermal stability. These advanced materials withstand higher temperatures than metal alternatives, often eliminating the need for additional thermal blankets.

Application-Specific Tuning: Medical vs Industrial Use

Medical devices demand unique battery characteristics compared to industrial applications. For healthcare equipment, custom battery solutions help find the optimal balance between usage, performance, and device size. Medical applications specifically require minimized battery replacement frequency and advanced monitoring features to ensure reliability for life-saving functions.

Industrial applications typically prioritize different attributes. These environments often need batteries capable of withstanding temperature extremes (-40°C to +85°C), supporting high current pulses, and offering extended cycle counts up to 5,000 full charge cycles.

Contact us today for custom battery solutions tailored to your specific application needs.

Custom lithium-ion battery pack designs enable application-specific optimization that standard solutions simply cannot match, making them worth considering despite potentially higher lithium ion battery pack prices.

Development Timelines and Certification Requirements

Project timeline management determines the success of battery implementation programs. Development periods and certification requirements must be factored into project schedules to prevent costly delays and ensure regulatory compliance.

Standard Packs: 4-Week Average Lead Time

Standard typically achieve availability within approximately 4 weeks following order placement. This expedited timeline results from manufacturers having previously developed battery management system modules that can be rapidly deployed. The process follows a defined sequence:lithium-ion battery packs

- Quote generation: 3-5 days depending on complexity

- Proof drawing creation: 2-3 days

- Customer approval: 3-5 days

- Sample production: Typically completed within 10 weeks

Standard solutions require some design and assembly work, resulting in modest non-recurring engineering charges.

Custom Packs: 8-12 Weeks Design + 4-6 Weeks Prototyping

Custom lithium-ion battery pack development requires substantially extended timelines. The electrical design phase alone spans 4-6 weeks. Prototype development adds another 4-6 weeks, pending cell availability. The development process includes:

- Mechanical design: 4-6 weeks

- Software/firmware development: 4-5 weeks

- 3D printing modeling: 5-10 days

- Injection molded enclosure tooling: 8-10 weeks

Battery packs requiring often need 10-20 weeks for sample production. Final production typically adds 10 more weeks unless long-lead items create additional delays.custom BMS and enclosures

Certification Requirements: UN 38.3, UL, IEC

Lithium batteries require specific certifications prior to shipping or implementation:

UN 38.3 – Mandatory for international lithium battery transport. This certification subjects batteries to eight rigorous tests including altitude simulation, thermal cycling, vibration, shock, external short circuit, impact, overcharge, and forced discharge. The process requires 17 sample packs and takes 6-8 weeks to complete.

UL 2054 – American standard for portable battery safety. Testing demands 55 sample packs and spans 12-14 weeks, with total certification time reaching 20-24 weeks.

IEC 62133 – International standard for rechargeable battery safety. This certification requires 33 samples and approximately 8-10 weeks of testing.

These certification requirements add significant time and expense—ranging from $460-$7000 for UN 38.3 testing alone—making them critical considerations in project planning.

Cost and Value Considerations

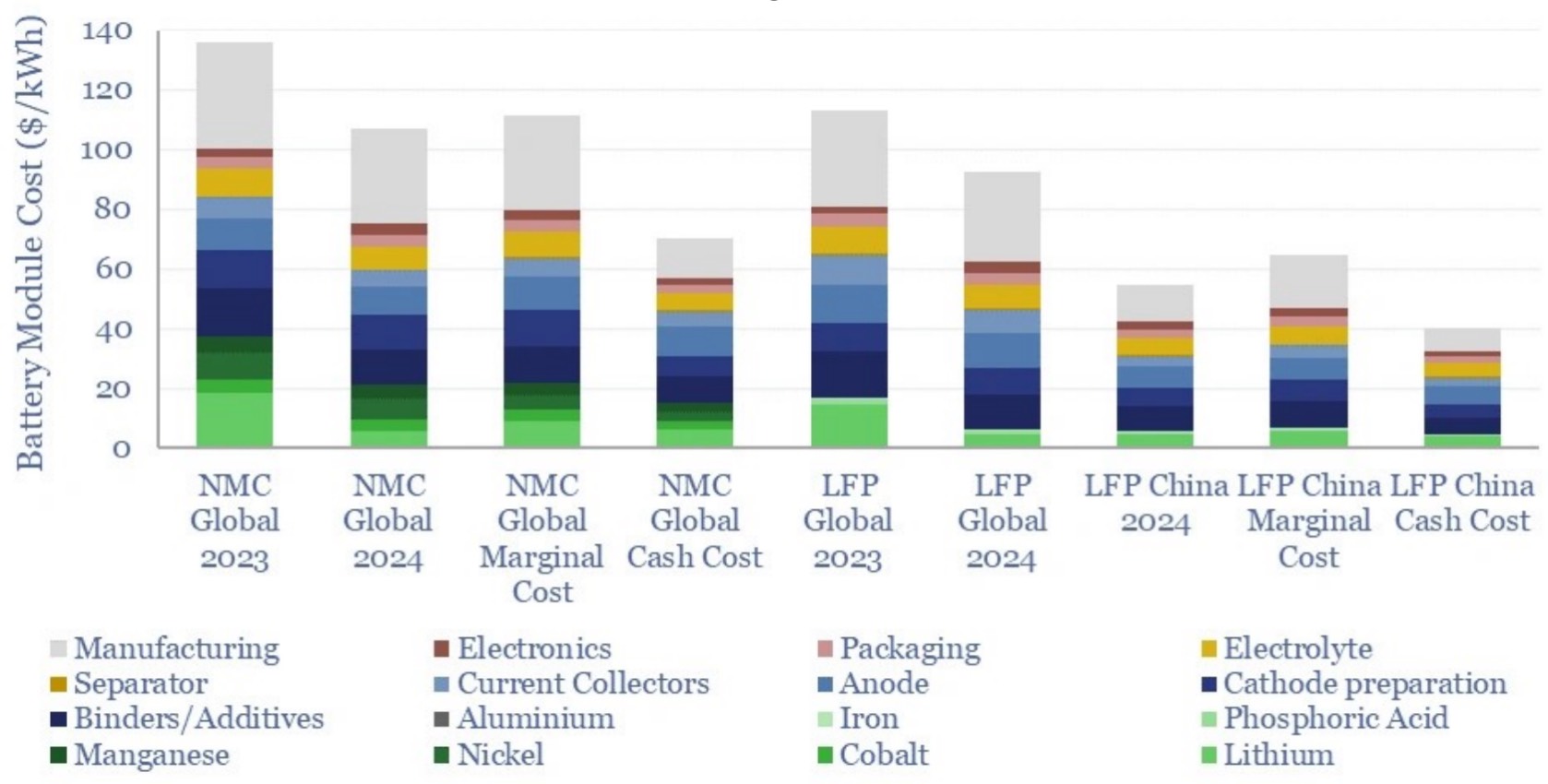

Image Source: Thunder Said Energy

Financial factors frequently determine the final selection between standard and custom battery solutions. The complete cost analysis extends beyond initial purchase price to encompass total lifecycle value and operational considerations.

Unit cost comparison: standard vs custom

Standard lithium-ion battery packs typically cost two to four times less than custom alternatives for initial procurement. A standard 12V 100Ah battery ranges from $150-$300, while comparable custom lithium-ion solutions cost $500-$1200. This price differential reflects the advanced materials, precision manufacturing processes, and sophisticated safety systems including Battery Management Systems (BMS) incorporated in custom designs.

However, custom batteries often achieve competitive per-unit pricing with adequate lead time. The actual cost advantage depends on production volume and project timeline requirements.

Impact of design complexity on lithium ion battery pack price

Customized battery pack pricing depends on several technical factors:

- Chemistry selection: Lithium chemistries exceed nickel-based alternatives in cost, though prices have declined significantly over recent decades

- Material choices: Component selections represent 78-82% of total pack costs

- Intelligence features: Smart battery capabilities including fuel gaging, state-of-health monitoring, and advanced communication protocols increase costs proportionally

- Enclosure design: Aluminum provides cost savings but compromises conductivity and corrosion resistance compared to copper or gold-plated alternatives

Contact our team for inquiries about both custom and standard battery packs to determine the most cost-effective solution for your project.

When the investment in a custom lithium-ion battery pack pays off

typically achieve ROI within 2-4 years of implementation. This payback period accelerates in intensive industrial applications. The economic benefits include:Custom lithium-ion battery packs

- Extended lifespan: Custom lithium options provide 2,000-3,500 charge cycles versus 1,000-1,500 for standard alternatives

- Reduced maintenance: No watering, terminal cleaning, or equalization charging required

- Higher efficiency: Custom lithium solutions achieve 96% charging efficiency compared to 75% for standard options

- Fewer replacements: Studies demonstrate custom lithium batteries can reduce 8-year battery costs by up to 56%

While upfront costs exceed standard alternatives, custom battery pack design represents the financially sound choice for long-term applications requiring reliability and optimal performance.

Comparison Table

| Aspect | Standard Battery Packs | Custom Battery Packs |

| Development Timeline | ~4 weeks | 8-12 weeks design + 4-6 weeks prototyping |

| Initial Cost | $150-$300 (12V 100Ah) | $500-$1,200 (comparable capacity) |

| BMS Capabilities | – Basic protection functions- Limited monitoring capabilities- Analog control technologies- Fixed parameter configurations | – Real-time cell voltage monitoring- Advanced SOC/SOH determination- Programmable operational parameters- Communication protocol support |

| Form Factor | Fixed dimensional configurations | Flexible geometries (curved, L-shaped, trapezoidal, ultra-thin) |

| Charge Cycles | 1,000-1,500 cycles | 2,000-3,500 cycles |

| Charging Efficiency | 75% | 96% |

| Design Flexibility | Limited to predetermined specifications | – Customizable voltage/capacity parameters- Optimized form factor design- Cell chemistry selection- Application-specific functionality |

| Certification Timeline | Pre-certified or standard process | – UN 38.3: 6-8 weeks- UL 2054: 20-24 weeks- IEC 62133: 8-10 weeks |

| Space Utilization | Standard dimensional constraints | 15-25% increased capacity within identical form factor |

| Long-term Value | Higher replacement frequency | Can reduce 8-year battery costs by up to 56% |

Conclusion

The selection between custom lithium-ion battery packs and off-the-shelf alternatives requires systematic evaluation of engineering requirements against project constraints. Standard battery packs provide immediate deployment advantages for applications with compressed development schedules, delivering adequate performance at reduced initial investment. Custom solutions offer superior long-term operational value through application-specific optimization, extended operational lifecycles, and precise form factor engineering.

Critical applications in medical devices or industrial equipment operating under extreme environmental conditions typically justify the enhanced safety features and application-specific tuning available in custom battery designs. The advanced BMS capabilities in custom packs—including real-time monitoring, programmable profiles, and sophisticated protection systems—provide substantial operational advantages over basic protection circuits in standard alternatives.

The economic analysis demonstrates that while custom lithium-ion battery pack prices initially exceed standard options by a factor of two to four, this investment typically achieves payback within 2-4 years through reduced maintenance requirements, decreased replacement frequency, and improved operational efficiency. Long-term applications requiring reliability and optimized performance often find custom battery pack design represents the most cost-effective solution despite extended development cycles.

The decision framework should evaluate both immediate project demands and long-term operational requirements. Contact our engineering team to discuss your specific battery requirements—whether standard battery packs or custom lithium-ion battery solutions designed for your application. Understanding these technical differences ensures selection of the power solution that aligns with engineering objectives, budget parameters, and performance specifications.

Key Takeaways

Engineers face critical tradeoffs when choosing between standard and custom lithium-ion battery solutions, with each option offering distinct advantages for different project requirements.

- Standard battery packs deliver 4-week lead times and lower upfront costs, while custom solutions require 8-12 weeks design plus prototyping but offer superior long-term value

- Custom battery packs provide 15-25% increased capacity in the same form factor through optimized design and can achieve 2,000-3,500 charge cycles versus 1,000-1,500 for standard options

- Advanced BMS in custom packs enables real-time monitoring, programmable profiles, and sophisticated safety features compared to basic protection in standard solutions

- Despite 2-4x higher initial costs, custom lithium-ion batteries often reduce 8-year total costs by up to 56% through extended lifespan and 96% charging efficiency

- Custom solutions justify investment for critical applications requiring specific form factors, extreme environment operation, or application-specific performance optimization

The choice ultimately depends on balancing immediate timeline needs against long-term performance requirements and total cost of ownership considerations.

FAQs

Q1. What are the main differences between standard and custom lithium-ion battery packs?

Standard packs offer quicker availability (around 4 weeks) and lower initial costs, while custom packs provide optimized performance, longer lifespans (2,000-3,500 charge cycles), and tailored designs but require 8-12 weeks for development plus prototyping.

Q2. How do Battery Management Systems (BMS) differ in standard vs. custom battery packs?

Standard packs typically have basic BMS with limited monitoring and fixed configurations. Custom packs feature advanced BMS with real-time cell monitoring, programmable parameters, and sophisticated safety features.

Q3. Are custom lithium-ion battery packs worth the higher initial cost?

While custom packs can cost 2-4 times more initially, they often pay off within 2-4 years through reduced maintenance, fewer replacements, and higher efficiency (96% charging efficiency vs. 75% for standard packs).

Q4. What certification requirements apply to lithium-ion battery packs?

Key certifications include UN 38.3 for transportation (6-8 weeks), UL 2054 for portable battery safety (20-24 weeks), and IEC 62133 for rechargeable battery safety (8-10 weeks). These add significant time and cost to development.

Q5. How do custom lithium-ion battery packs improve space utilization?

Custom packs can be designed in flexible shapes (curved, L-shaped, trapezoidal) to maximize available space, potentially increasing capacity by 15-25% compared to standard packs of the same size.