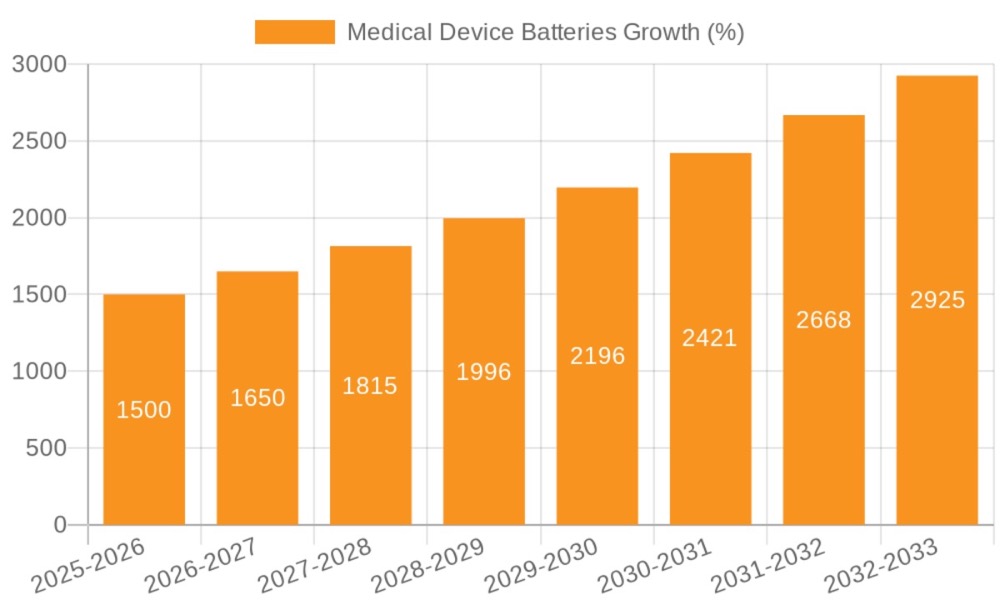

For designers and engineers in the medical device space, the Portable Oxygen Concentrator (POC) represents a pinnacle of life-enhancing technology. The market is expanding rapidly, driven by an aging population and a systemic shift toward home healthcare. At the heart of this revolution is a single, defining promise to the patient: freedom. The freedom to travel, to engage with family, and to live a life untethered from a wall outlet.

This promise of mobility rests squarely on the shoulders of your device’s power source. The lithium-ion battery pack is not merely a component; it is the heart of a modern POC. Selecting—or more accurately, designing—the right battery system is one of the most critical decisions in the product development lifecycle. It’s a complex process fraught with technical trade-offs and regulatory hurdles, where a misstep can compromise device performance, patient safety, and your brand’s reputation.

The medical device battery market is experiencing unprecedented growth, with portable oxygen concentrators representing one of the fastest-growing segments. This guide will walk you through the essential considerations and common pain points in designing a battery solution for your next POC, helping you navigate the path from concept to a reliable, market-leading product.

The Core Engineering Challenge: The Power-to-Weight Paradox

Before diving into chemistries and circuits, it’s crucial to acknowledge the central conflict that governs all design choices for a POC battery: the power-to-weight paradox.

External Lithium-ion Battery Pack Design

Patients and clinicians universally demand two things: maximum battery life and minimum weight. A patient needs their device to last through a full day of appointments or a cross-country flight, eliminating “range anxiety”. However, the very demographic relying on these devices is often elderly or frail, for whom every pound is a significant physical burden. A POC that is too heavy ceases to be truly portable, defeating its primary purpose.

Real-World Impact: Patient Mobility Statistics

Under 5 lbs

95% patient satisfaction and daily use

5-8 lbs

78% patient satisfaction with reduced mobility

Over 8 lbs

45% patient satisfaction, often abandoned

This paradox is the fundamental design constraint. Your goal is not simply to find the battery with the highest milliamp-hour (mAh) rating, but to achieve the optimal balance of energy density, safety, longevity, and intelligence within a strictly defined weight and form factor. Every decision, from cell chemistry to enclosure material, must be weighed against this core challenge.

Critical Decision #1: Choosing the Right Lithium Chemistry

Not all lithium-ion batteries are created equal. The specific chemistry of the cells you choose will have the most profound impact on your device’s safety profile and long-term performance. While many consumer electronics use chemistries that prioritize maximum energy density, medical devices demand a different set of priorities.

LiFePO4 vs Standard Li-ion Thermal Runaway Characteristics

Chemistry Comparison Analysis

| Feature | Standard Li-ion (NMC/LCO) | Lithium Iron Phosphate (LiFePO4) |

| Primary Advantage | High Energy Density | Superior Safety & Longevity |

| Typical Cycle Life | 300–1,000 cycles | 2,000–5,000+ cycles |

| Thermal Runaway Temp. | ~200°C | >350°C |

| Safety Profile | Good | Excellent |

| Total Cost of Ownership | Higher due to frequent replacements | Lower due to extended lifespan |

| Weight per Wh | 150-180 g/Wh | 180-220 g/Wh |

| FDA Approval | Standard requirements | Enhanced safety documentation |

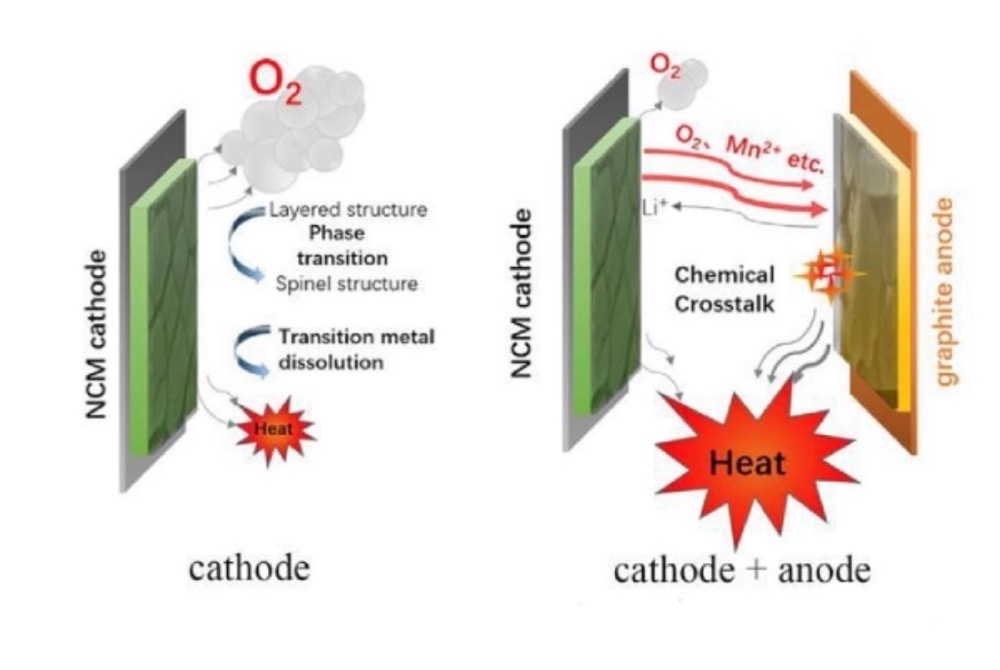

Standard Lithium-Ion (NMC, LCO): The Consumer Choice

These chemistries are ubiquitous in laptops and smartphones for a reason: they offer excellent energy density, packing a lot of power into a light package. However, for a life-sustaining medical device, they present two significant drawbacks:

- Limited Cycle Life:Often degrading noticeably after 500-800 cycles, leading to more frequent and costly battery replacements

- Thermal Safety Concerns:Their oxide-based cathodes make them more susceptible to thermal runaway if damaged or improperly managed

Thermal Runaway Process and Prevention Strategies

Lithium Iron Phosphate (LiFePO4): The Medical Grade Choice

For medical applications like POCs, LiFePO4 is increasingly the superior choice. Its phosphate-based chemistry is intrinsically more stable, making it exceptionally resistant to thermal runaway even under extreme conditions. This inherent safety is a critical advantage.

Key Benefits for POC Applications:

- Exceptional Cycle Life:Often exceeding 3,000 cycles before significant capacity degradation

- Thermal Stability:Operating safely at temperatures up to 60°C

- Lower Total Cost of Ownership:Despite higher initial cost, longevity dramatically reduces TCO

- Regulatory Advantages:Enhanced safety profile simplifies FDA approval process

For a POC designer, the choice is clear: prioritizing the unparalleled safety and long-term reliability of LiFePO4 provides a robust foundation for a medical-grade device. Large Power’s 26650 6.8Ah 12.8V LiFePO4 Battery for Medical Device exemplifies this approach with proven reliability in respiratory equipment.

Critical Decision #2: Architecture and User Experience

The physical design of the battery pack is just as important as its internal chemistry. It directly impacts how the user interacts with the device daily.

Modular Lithium Battery Pack System for Medical Devices

Internal vs. External Batteries: The Serviceability Factor

While internal (built-in) batteries can create a sleek, unified device, they present a major serviceability issue. An external, user-swappable battery design is far superior for POCs for several critical reasons:

Advantages of External Battery Design:

- Extended Runtime:Patients can carry spare batteries, effectively doubling or tripling their time away from a power source

- Minimal Downtime:Battery swapping takes seconds vs. hours of charging

- Cost Effectiveness:Replace batteries individually rather than entire devices

- User Confidence:Visible battery status and immediate backup availability

Modular Multi-Cell Packs: Flexibility Meets Function

Leading brands offer modular battery options, such as standard 8-cell and extended 16-cell packs. This gives users a choice: a lighter pack for short errands or a heavier, longer-lasting pack for all-day trips.

Different Battery Pack Configurations for Various Runtime Requirements

Design Considerations:

- Standardized Connectors:Must accommodate different physical footprints while ensuring secure connection

- Mechanical Alignment:Self-aligning designs prevent user frustration and connection failures

- Environmental Sealing:IP65 rating minimum for outdoor use scenarios

User-Friendly Design: Engineering for Limited Dexterity

The battery swapping mechanism must be intuitive for users who may have limited dexterity due to age or medical conditions. Essential features include:

- Large Release Buttons:Minimum 15mm diameter with tactile feedback

- Clear LED Indicators:5-level charge status visible in daylight

- Robust Connectors:Gold-plated contacts rated for 10,000+ insertion cycles

- Error-Proof Design:Physical keying prevents incorrect insertion

Large Power’s 14.4V 6700mAh 18650 Lithium Battery Pack demonstrates these principles with an intelligent battery design specifically engineered for oxygen concentrator applications.

Navigating the Five Critical Pain Points in POC Battery Design

Advanced Battery Management System Architecture for Medical Applications

Beyond chemistry and form factor, the journey of integrating a power source is filled with potential pitfalls. Anticipating these challenges is key to a successful product launch.

1 Inconsistent Quality and Reliability

For a life-sustaining device, inconsistent performance is unacceptable. A battery that fails prematurely or delivers unpredictable runtimes can be a critical medical event.

The Scale of the Problem

Healthcare industry data reveals alarming statistics:

- 50% of hospital service callsare battery-related issues

- Average hospital battery replacement cost:$400-800 per incident

- Patient safety events:15% involve power system failures

Medical-Grade Battery Manufacturing Quality Standards

Your battery solution must be manufactured under ISO 13485 standards – the global standard for medical device quality management systems. This ensures full traceability, consistent performance, validated testing, and complete documentation for regulatory compliance.

2 High Total Cost of Ownership (TCO)

The initial price of the battery pack is only a fraction of its true cost. A battery with a short cycle life will require multiple expensive replacements over the POC’s lifespan.

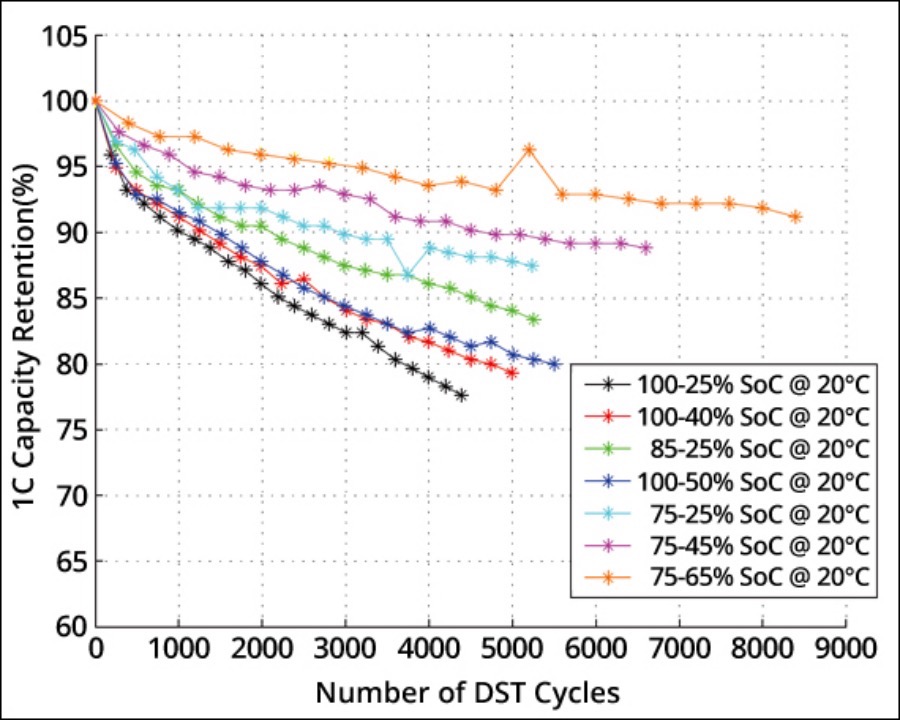

Battery Cycle Life and Performance Degradation Analysis

TCO Analysis: 5-Year Ownership Model

Standard Li-ion Battery System:

- Initial Cost: $200

- Replacement Frequency: Every 18 months

- Total Replacements: 3-4 batteries

- 5-Year TCO: $800-1,000

LiFePO4 Battery System:

- Initial Cost: $350

- Replacement Frequency: Every 5+ years

- Total Replacements: 0-1 batteries

- 5-Year TCO: $350-500

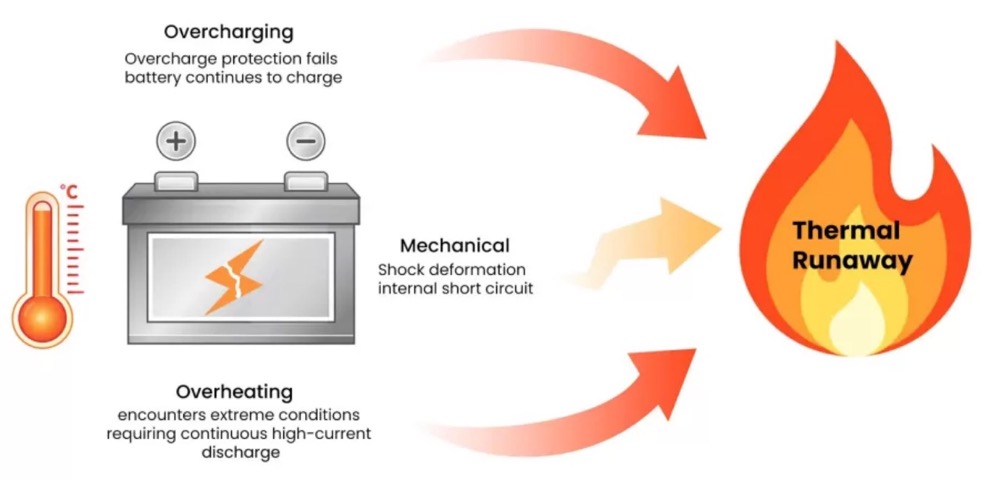

3 Thermal Management and High Current Demands

A POC’s compressor requires high bursts of current to function, placing significant stress on the battery and generating heat. This heat can accelerate cell degradation and, if unmanaged, pose a safety risk.

Advanced Thermal Management and Safety Systems

Typical POC Power Demands:

- Standby Mode:2-5W continuous

- Compressor Operation:35-60W pulse (2-5 seconds)

- Peak Current:8-12A for startup transients

- Duty Cycle:30-50% depending on flow rate

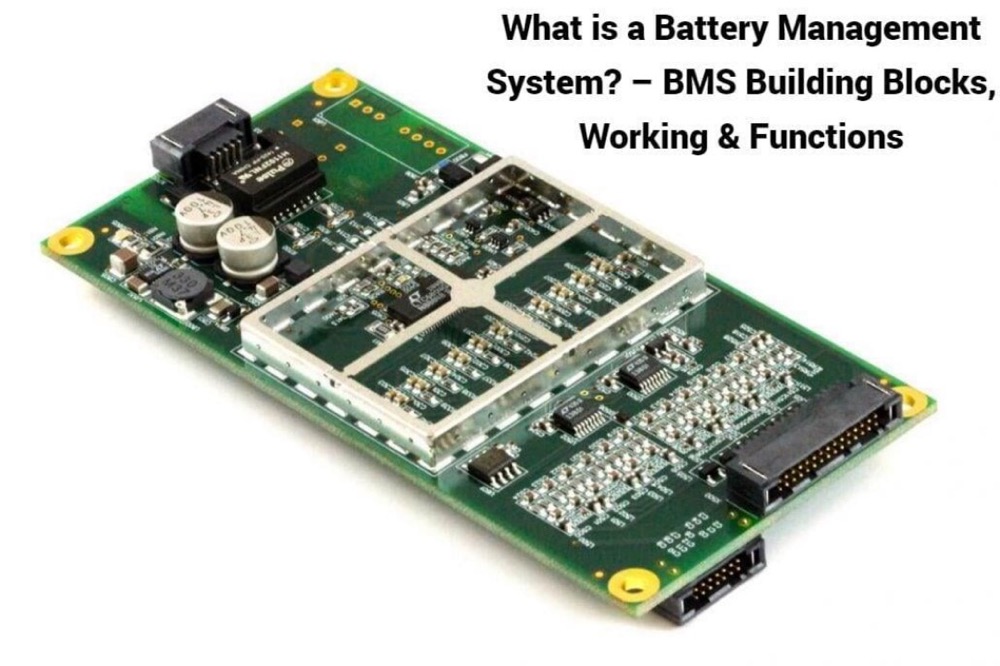

4 The “Dumb” Battery Problem

A simple battery pack is a black box. It cannot communicate its status to the host device or the user, leading to inaccurate “fuel gauges” that create patient anxiety.

Smart Battery Management System with Real-Time Communication

Smart Battery Communication Features:

- State of Charge (SoC):Accurate remaining capacity percentage

- State of Health (SoH):Battery condition and degradation status

- Time to Empty:Precise runtime estimation based on current load

- Cycle Count:Track battery age and plan replacements

- Temperature:Monitor thermal conditions for safety

Comprehensive Battery Management and Communication System

5 Fragmented Supply Chains and Integration Headaches

Attempting to source individual cells, a generic BMS, and a custom enclosure from separate vendors can quickly become an engineering and logistical nightmare.

The Hidden Costs of Fragmentation

Technical Risks:

- Component incompatibility

- Quality variations

- Integration challenges

- Testing complexity

Supply Chain Risks:

- Single point of failure

- Quality blame game

- Inventory complexity

- Regulatory complications

The Solution: A Custom, Vertically Integrated Partnership

Navigating these complex, high-stakes challenges leads to a clear conclusion: the optimal power source for a modern POC is not an off-the-shelf component, but a fully integrated, custom-engineered system.

Partnering with a specialist in custom medical battery solutions like Large Power transforms the design process from a series of compromises into a streamlined path to excellence. Our vertically integrated approach means we are not just a supplier, but an extension of your engineering team.

Why Large Power is the Ideal Partner

Proven Track Record:

- 23+ Yearsof medical device battery experience

- ISO 13485 Certifiedmanufacturing facilities

- FDA-Compliantdocumentation and processes

- Global Supply Chainwith local support

Technical Capabilities:

- Custom Cell Designoptimized for medical applications

- Advanced BMS Technologywith smart communication

- Thermal Engineeringsophisticated heat management

- Regulatory Supportcomplete medical device documentation

Our “Four Highs and One Low” Philosophy

High Energy Density

Maximum power in minimal weight

High-Rate Discharge

Reliable high current performance

High-Temperature Resistance

Safe operation in challenging environments

High Safety

Medical-grade safety standards

Low-Temperature Performance

Reliable operation in all climates

Specific POC Battery Solutions

Standard Capacity Solutions:

- 4V 6700mAh 18650 Lithium Battery Pack– Intelligent battery with SMBus communication

- 8V 4400mAh Low Temperature Battery– Specialized for harsh environments

Medical Ventilator Solutions:

- 4V 6.7Ah Li-ion Battery Pack– High-reliability for life-support equipment

Engineering Support and Development Process

Collaborative Design Approach

Our engineering team works closely with your development team through every phase:

1 Requirements Analysis

- Power profile analysis and optimization

- Mechanical constraints and thermal modeling

- Regulatory pathway planning

- Cost target establishment

2 Custom Design

- Cell selection and validation testing

- BMS design and communication protocol development

- Mechanical design and prototyping

- Safety testing and certification planning

3 Validation and Production

- Prototype testing and refinement

- Pilot production and quality validation

- Regulatory documentation support

- Full-scale manufacturing ramp-up

Quality Assurance and Testing

Every battery pack undergoes comprehensive testing:

Safety Testing:

- UL 1998certification for medical device batteries

- IEC 62133lithium battery safety standards

- UN 38.3transportation safety testing

- Custom medical device specific testing protocols

Performance Validation:

- Cycle Life Testing:Validated under real-world conditions

- Environmental Testing:Temperature, humidity, vibration, shock

- EMC Testing:Electromagnetic compatibility for medical environments

- Accelerated Aging:Predict long-term performance and reliability

The Future of POC Battery Technology

As the medical device industry continues to evolve, several emerging technologies will further enhance POC battery performance:

Next-Generation Battery Technologies

Solid-State Batteries:

- Enhanced safety through elimination of liquid electrolyte

- Higher energy density for lighter weight solutions

- Extended temperature operating range

- Expected commercial availability: 2026-2028

Silicon Nanowire Anodes:

- 40% increase in energy density over current technology

- Maintained cycle life through advanced engineering

- Compatible with existing BMS technology

- Currently in development phase

Advanced Battery Management

AI-Powered Analytics:

- Predictive failure analysis using machine learning

- Optimized charging profiles based on usage patterns

- Remote health monitoring and diagnostics

- Integration with telemedicine platforms

Conclusion: Powering Patient Freedom

The battery is the engine of patient freedom. Don’t let it be an afterthought. The complexity of modern POC battery systems demands expertise that spans chemistry, electronics, mechanical engineering, regulatory compliance, and manufacturing quality systems.

Empowering Patient Independence Through Advanced Battery Technology

By partnering with an expert in custom medical battery design, you can solve the power-to-weight paradox and deliver a Portable Oxygen Concentrator that is:

Safer

Medical-grade safety standards and certifications

More Reliable

Proven performance with extensive testing and validation

Cost-Effective

Lower total cost of ownership through superior longevity

User-Friendly

Intelligent features that enhance patient experience

This comprehensive approach gives your product a powerful competitive edge and your patients the independence they deserve.