Rechargeable lithium-ion batteries for oxygen concentrators can deliver up to 13 hours of operation using double battery configurations on full charge. The reliability of your directly impacts your mobility and independence, making power system selection a critical healthcare decision.battery backup for oxygen concentrator

Portable oxygen concentrators typically operate on rechargeable battery systems that provide 3 to 12 hours of runtime. This operational window depends on device specifications, flow rate settings, and usage patterns. Battery cells have a finite service life of approximately 500 full charge/discharge cycles, which establishes the importance of proper battery selection and maintenance protocols for sustained performance.

Federal aviation regulations require oxygen concentrator users to carry additional fully-charged batteries during air travel. The required battery capacity must support at least 150% of expected flight duration. Battery backup selection extends beyond basic runtime calculations to include battery chemistry understanding, maintenance specifications, and individual oxygen therapy requirements.

This technical guide examines battery options for oxygen therapy devices. The scope includes standard versus extended battery configurations, runtime optimization strategies, and maintenance procedures necessary for reliable respiratory care equipment operation.

Oxygen Requirements and Usage Patterns Analysis

Battery backup selection for oxygen concentrators requires evaluation of individual oxygen therapy specifications, mobility requirements, and flow delivery systems. These three parameters determine the power management approach necessary for reliable respiratory support.

Daily Oxygen Flow Rate Requirements

Oxygen therapy prescriptions specify flow rates measured in liters per minute (LPM). This prescribed flow rate establishes the baseline power consumption that directly impacts battery capacity requirements. Higher LPM settings increase power draw, reducing operational time between charging cycles.

Healthcare providers establish oxygen requirements through diagnostic testing protocols. measurements provide rapid blood oxygen saturation readings, while arterial blood gas (ABG) testing delivers precise oxygenation data. The objective involves maintaining blood oxygen saturation within physician-defined parameters during both resting and active states.Pulse oximeter

Oxygen consumption varies throughout daily activities. Physical exertion increases oxygen demand similar to how vehicle fuel consumption rises during acceleration or uphill driving. Battery backup systems must accommodate peak oxygen requirements rather than baseline consumption levels to prevent inadequate power during high-demand periods.

Oxygen therapy needs may progress over time. Patients currently operating devices at maximum settings should select battery systems with capacity reserves to support potential future increases in therapeutic requirements.

Mobility Patterns and Power Access

Home-based users with consistent electrical outlet access can utilize standard battery configurations for occasional mobility needs. Active individuals requiring frequent travel, errands, or extended periods away from power sources need expanded battery solutions.

Air travel presents specific battery challenges. Airlines mandate of expected flight duration. A 4-hour flight requires minimum 6-hour battery capacity to accommodate delays and operational contingencies.extra batteries for at least 150%

Critical mobility assessment factors include:

- Maximum duration between charging opportunities

- Air travel frequency and duration requirements

- Daily charging access patterns

- Seasonal activity variations affecting power needs

Portable oxygen concentrators (POCs) provide travel flexibility with regulatory limitations. All continuous flow POCs receive FAA approval for aircraft use, though airlines require 48-hour advance notification.

Flow Delivery System Impact on Battery Performance

Flow delivery method represents the primary factor affecting battery runtime performance. Two distinct approaches offer different power consumption characteristics.

Pulse dose systems activate only during inhalation cycles, utilizing pressure sensors in nasal cannula connections. This demand-based delivery significantly extends battery life compared to continuous operation. Standard batteries in pulse dose mode typically provide 4.5 hours at setting 1, with larger batteries extending runtime to 9 hours.

Continuous flow systems maintain steady oxygen delivery independent of breathing patterns. This approach ensures consistent oxygen supply but reduces battery performance to 1-10 hours depending on flow settings and battery specifications. Continuous flow becomes necessary under specific clinical conditions:

- Sleep therapy applications where shallow breathing prevents pulse dose sensor activation

- CPAP or BiPAP machine integration that interferes with pulse detection systems

- Advanced respiratory conditions requiring higher oxygen concentrations

Many portable concentrators incorporate both delivery modes with dramatically different power consumption profiles. A typical device might offer continuous flow rates of 0.5-3.0 LPM alongside pulse flow settings 1-9, creating significant battery performance variations between operating modes.

Battery Backup Configuration Options

Battery backup selection requires evaluation of multiple configuration options, each designed to address specific operational requirements and usage patterns. The available solutions present distinct performance characteristics and trade-offs that directly impact device functionality.

Standard Battery Performance vs Extended Capacity Systems

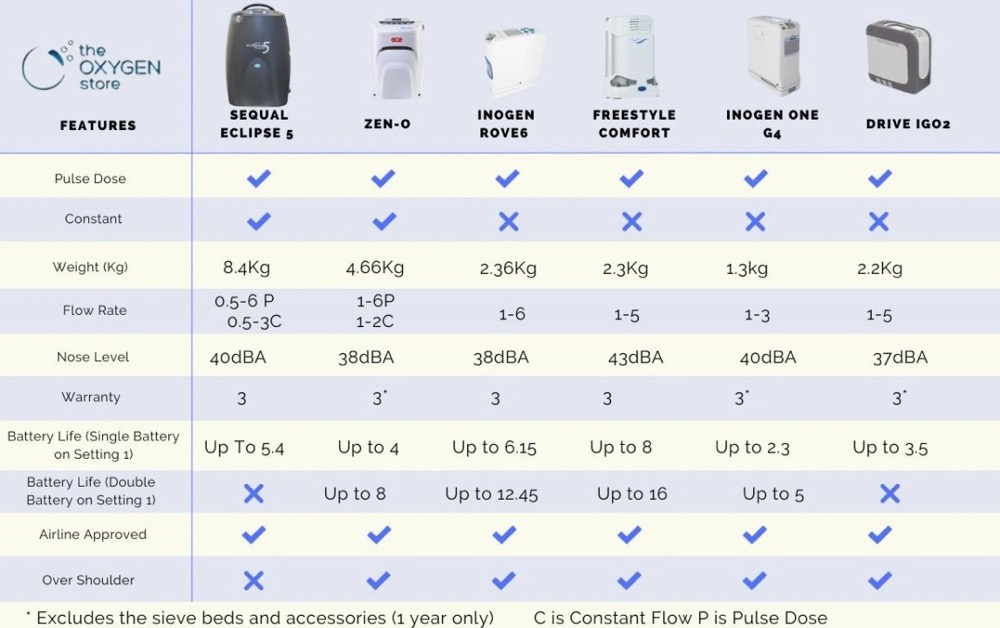

Standard battery configurations deliver 2.7 to 6.25 hours of operation on lower flow settings. Extended capacity systems provide substantially increased runtime— for models such as the Inogen Rove 6. This enhanced performance requires accepting increased weight penalties. The Philips SimplyGo standard battery weighs 1.1 pounds compared to 2.1 pounds for the extended version.up to 12.75 hours at setting 1

Charging time parameters differ significantly between configurations. Standard batteries reach full capacity in approximately 4 hours from complete discharge, while extended systems require up to 8 hours for full charge cycles. The capacity justifies the extended charging periods for applications requiring prolonged operation away from AC power sources.nearly doubled runtime

Integrated vs Modular Battery Architecture

Integrated battery systems provide streamlined device profiles with unified mechanical design. The LifeChoice Activox 4L employs internal battery architecture delivering up to 10 hours of operation at setting 1. Integrated systems present maintenance limitations—battery failure requires complete unit service rather than component-level replacement.

offer operational flexibility through hot-swap capability—depleted batteries can be replaced with charged units without interrupting oxygen flow. This modular approach enables independent charging of spare battery modules while maintaining continuous device operation, regardless of AC power availability.Swappable batteries

and Alternative Power SystemsPortable power stations

Medical-grade portable power stations function as uninterruptible power supply (UPS) systems delivering pure sine wave output required for sensitive medical equipment. These systems typically provide 30 minutes to 4 hours of backup capacity depending on concentrator power consumption.

Solar charging systems provide extended independence capabilities. The Geneforce Emergency Power System supports multiple charging methods including wall outlets, solar panels, and gas generators. Solar-equipped systems can store up to 72 hours of power at full charge, ensuring operation during extended power outages.

Advanced power stations incorporate multiple outlet configurations, rapid charging capabilities, and intelligent power management systems with automatic source switching. Fast switchover technology—as rapid as 10 milliseconds—maintains uninterrupted operation for life-critical equipment.

Battery Backup Transportation Requirements

Air travel with oxygen therapy equipment requires compliance with federal transportation regulations. Battery specifications, quantity requirements, and safety protocols determine successful transport without operational disruptions.

Federal Aviation Administration Battery Specifications

The Federal Aviation Administration (FAA) has established acceptance criteria for portable oxygen concentrators (POCs) used on aircraft. POCs approved for air transport must display the following statement in red lettering: “The manufacturer of this POC has determined this device conforms to all applicable FAA acceptance criteria for POC carriage and use on board aircraft”.

Battery watt-hour ratings represent the critical specification for air transport eligibility. The FAA restricts lithium-ion batteries to a maximum of 160 watt-hours (Wh). This limitation affects specific POC models with high-capacity battery systems. The Inogen One G5 double battery configuration rates at 188.8 Wh, which exceeds FAA limits and prohibits air transport, while the single battery configuration at 92.2 Wh meets regulatory requirements.

Battery Quantity Requirements for Air Transport

establish minimum battery capacity requirements for air travel. Airlines may require battery capacity sufficient for 150% of expected flight duration. A 4-hour flight necessitates battery capacity for 6 hours of operation. This specification accounts for flight delays, layovers, and unexpected operational conditions.Department of Transportation (DOT) regulations

Contact your airline prior to ticket purchase to confirm specific requirements for physician documentation and battery certification. Airlines generally permit additional batteries under 160 Wh, but individual carriers may impose quantity restrictions.

Battery Transport Safety Protocols

Lithium batteries must be transported in carry-on baggage exclusively—checked baggage storage is prohibited. Battery protection requirements include:

- Original manufacturer packaging • Individual plastic bag storage

- Terminal insulation with protective tape

These protection methods prevent short circuits that could cause overheating or thermal events. Recharge all batteries upon arrival at your destination to ensure adequate power for return travel.

Battery Life Optimization and Performance Maintenance

Image Source: 1st Class Medical

Proper maintenance protocols for oxygen concentrator battery systems directly impact operational lifespan and reliability. are designed for 350-500 recharge cycles, making systematic care procedures essential for maintaining performance specifications and safety standards.Lithium-ion batteries

Discharge Management Protocols

Battery charge levels between 20% and 80% during normal operation significantly reduce cell degradation in lithium-ion systems. Complete discharge cycles create stress conditions within battery components, accelerating capacity loss and reducing overall service life. Extended periods at zero charge cause accelerated deterioration of internal cell chemistry.

Environmental Control Requirements

Temperature management is critical for battery cell preservation. Operating and storage temperatures must remain within 41°F to 104°F (5°C to 40°C). Temperatures exceeding 104°F (40°C) cause permanent damage to lithium-ion cell structure. Heat exposure from direct sunlight or enclosed vehicles represents the primary cause of premature battery failure. Charging operations require adequate ventilation to prevent thermal buildup.

Calibration and Inspection Procedures

Manufacturers recommend monthly to maintain accurate power monitoring. The calibration protocol involves:battery recalibration

- Disconnect all external power sources, retaining battery connection only

- Operate concentrator until complete battery depletion occurs

- Allow minimum one-hour rest period for cell stabilization

- Charge to 100% capacity without interruption

This procedure synchronizes the battery management system with actual available capacity, preventing unexpected power failures. Visual inspection should identify cell swelling, electrolyte leakage, excessive heating, or discoloration—any condition requiring immediate battery replacement.

Long-term Storage Management

Batteries stored for periods exceeding 2-3 months require maintenance at approximately 50% charge level. Zero-charge storage conditions accelerate permanent capacity loss. Natural degradation occurs regardless of usage patterns, but proper storage conditions minimize this deterioration. Multiple battery systems benefit from rotation schedules—label individual units and alternate weekly usage to ensure uniform wear patterns.

Battery terminal maintenance involves regular cleaning with dry, lint-free materials to remove contamination that affects charging efficiency and electrical connections. These maintenance procedures maximize both operational performance and equipment longevity for oxygen concentrator power systems.

Battery Backup Purchase Decision Framework

Image Source: CMI Health

Battery backup investment for oxygen concentrators requires evaluation of multiple technical and economic factors beyond initial purchase price. The selection process involves analyzing cost-effectiveness, warranty coverage, and specialized application requirements.

Battery Pricing Structure and Value Analysis

Battery pricing varies significantly based on capacity specifications and design features:

- Standard batteries: $200-$400

- Extended batteries: $300-$600

- Backup power stations: $400-$100,000

command higher prices but ensure compatibility with device specifications and safety parameters. Aftermarket alternatives begin at $50, although performance and reliability vary considerably—certified brands provide necessary quality assurance. Cost-per-hour runtime analysis frequently demonstrates that higher-capacity batteries deliver superior long-term value.Official manufacturer (OEM) batteries

Warranty Coverage and Service Parameters

Warranty terms differ among manufacturers, with typical coverage periods of 12 months for accessories and batteries, extending to 36 months for primary devices. Warranty transferability requires verification—most manufacturer warranties apply exclusively to original purchasers.

Service terms include “return-to-base” warranty policies, which place shipping cost responsibility on the customer for repair returns. Extended warranty packages offer alternative coverage options, with some manufacturers providing 5-year protection versus standard 3-year terms.

Application RequirementsCustom Battery Solutions

Custom battery development becomes viable for specific technical requirements—applications requiring unique altitude performance characteristics, weight optimization without capacity reduction, or specialized environmental operating conditions. Third-party manufacturers can engineer batteries with precise voltage specifications, integrated safety circuits, and smart functionality including Bluetooth connectivity. Custom solutions address performance requirements that standard configurations cannot accommodate while maintaining regulatory compliance and safety standards.

Technical Summary

Battery backup selection for oxygen concentrators requires systematic evaluation of individual oxygen therapy requirements and operational parameters. The selection process involves matching battery capacity to prescribed flow rates, determining power requirements for specific usage patterns, and ensuring compliance with transportation regulations.

Oxygen concentrator battery systems fall into distinct categories with measurable performance differences. Standard batteries provide 2.7 to 6.25 hours of operation, while extended configurations deliver up to 12.75 hours at setting 1. Swappable battery designs offer operational flexibility through hot-swap capabilities, enabling continuous operation during battery replacement procedures.

Federal aviation regulations establish specific technical requirements for air transport. Lithium-ion batteries must remain below 160 watt-hours for airline approval. Passengers must carry battery capacity sufficient for 150% of flight duration to account for operational delays and safety margins.

Battery maintenance protocols directly impact system longevity and reliability. Lithium-ion cells designed for 350-500 recharge cycles require specific charge management between 20-80% capacity levels. Temperature control within 41°F to 104°F (5°C to 40°C) prevents permanent cell damage. Monthly calibration procedures maintain accurate capacity readings and prevent unexpected power failures.

The investment in quality battery backup systems extends beyond initial cost considerations. Original equipment manufacturer (OEM) batteries range from $200-$600 and provide guaranteed device compatibility. Extended warranty options offer up to 36 months of coverage for main devices, with 12-month coverage standard for battery accessories.

Proper battery backup selection ensures reliable oxygen therapy delivery while maintaining mobility and independence. The technical specifications and maintenance requirements outlined in this guide provide the foundation for informed decision-making regarding this critical respiratory care component.

Key Takeaways

Choosing the right battery backup for your oxygen concentrator requires understanding your specific oxygen needs, lifestyle patterns, and device requirements to ensure reliable power when you need it most.

- Match battery capacity to your oxygen flow rate and daily usage – Higher flow rates drain batteries faster, so calculate your maximum daily needs plus 150% for travel safety margins.

- Consider swappable batteries over built-in for maximum flexibility – Hot-swappable batteries allow continuous operation during battery changes and independent charging of spare units.

- Follow FAA regulations for air travel – Lithium batteries must be under 160 watt-hours, carried in carry-on luggage only, and you need enough power for 150% of flight duration.

- Maintain batteries between 20-80% charge for longevity – Avoid complete discharges and store in temperatures between 41-104°F to maximize the 350-500 cycle lifespan.

- Invest in quality over price for critical medical equipment – OEM batteries cost $200-600 but guarantee compatibility, while proper maintenance and monthly calibration maximize your investment.

The right battery backup system provides not just power, but peace of mind and independence, allowing you to maintain your lifestyle without constant worry about oxygen access during outings, travel, or power outages.

FAQs

Q1. How do I determine the right battery backup for my oxygen concentrator? Consider your daily oxygen needs, lifestyle, and device requirements. Calculate your maximum daily usage plus 150% for safety margins, especially when traveling. Choose a battery capacity that matches your oxygen flow rate and provides enough runtime for your typical activities away from power sources.

Q2. What are the advantages of swappable batteries over built-in ones? Swappable batteries offer greater flexibility. They allow for continuous operation during battery changes and independent charging of spare units. This is particularly useful for extended outings or travel, ensuring you always have a charged battery ready.

Q3. What are the FAA regulations for traveling with oxygen concentrator batteries? The FAA requires lithium batteries to be under 160 watt-hours and carried in carry-on luggage only. You must have enough battery power for 150% of your flight duration. Always check with your airline for their specific requirements regarding physician statements and battery documentation.

Q4. How can I maximize the lifespan of my oxygen concentrator battery? Maintain your battery charge between 20-80% for optimal longevity. Avoid complete discharges and store batteries in temperatures between 41-104°F (5-40°C). Perform monthly calibrations and regular inspections for any signs of wear or damage.

Q5. Is it worth investing in more expensive OEM batteries? While OEM (Original Equipment Manufacturer) batteries typically cost more, ranging from $200-600, they guarantee compatibility with your device. For critical medical equipment like oxygen concentrators, investing in quality over price is often advisable to ensure reliability and peace of mind.