Collaborative Robot (Cobot) Battery Solutions | Large Power

As a professional collaborative robot (cobot) battery manufacturer, Large Power focuses on the design and production of advanced lithium battery systems for robotic applications. With long battery life, fast charging capability, intelligent BMS, and high safety performance, we empower your cobots to operate smarter, longer, and more efficiently. Our battery solutions minimize downtime and maintenance costs while ensuring stable, continuous operation for precise and safe human–robot collaboration.

The Application of Collaborative Robots

Collaborative robots (cobots) are increasingly used across manufacturing, logistics, and service industries to enhance flexibility, precision, and safety in automation environments.

In manufacturing, cobots assist with repetitive and precise tasks such as assembly, welding, and inspection, working safely alongside human operators to increase productivity and consistency. In logistics and warehousing, cobots support packing, labeling, and sorting operations, improving efficiency in material handling while reducing labor intensity. In medical and laboratory settings, collaborative robots perform delicate tasks like sample transfer and sterilization, ensuring safety and precision in controlled environments.

Collaborative robots play a vital role in the transformation toward smart manufacturing and intelligent logistics, where flexibility, safety, and reliability are essential. As automation continues to evolve, the demand for compact, safe, and high-performance batteries is rapidly growing. Large Power specializes in developing advanced lithium battery systems for collaborative robots, offering long cycle life, fast charging capability, and stable performance. With intelligent BMS technology and proven manufacturing expertise, Large Power ensures that your cobots operate safely, efficiently, and continuously—empowering seamless human–robot collaboration in every workspace.

Solve the Pain Points of the Collaborative Robot Industry

Are You Facing These Challenges?

❌ Limited battery life, causing frequent interruptions during operation

❌ Slow charging speed, reducing overall production efficiency

❌ Heavy and bulky batteries, restricting robot arm flexibility and payload capacity

❌ Complex maintenance, increasing downtime and operational costs

❌ Insufficient communication interfaces, limiting real-time monitoring and control

Our Collaborative Robot Battery Solutions

We provide high-performance, lightweight, and intelligent lithium battery systems designed specifically for collaborative robots. These batteries address all the challenges above and help your cobots achieve smoother, safer, and more efficient operation.

Main Product Categories

Our industry-leading lithium battery solutions for collaborative robots (cobots) are widely applied in smart manufacturing, logistics automation, electronics assembly, healthcare, and laboratory operations. These batteries are engineered to meet the unique demands of cobots — offering compact size, high energy density, and intelligent management to ensure continuous, precise, and safe performance in human–robot collaborative environments.

Strategic partners include leading enterprises in industrial automation, robotics, and intelligent manufacturing, ensuring seamless integration and reliable performance across a wide range of collaborative robot applications. With proven engineering expertise and flexible customization, Large Power delivers the energy foundation for the next generation of smart, connected, and efficient robotic systems.

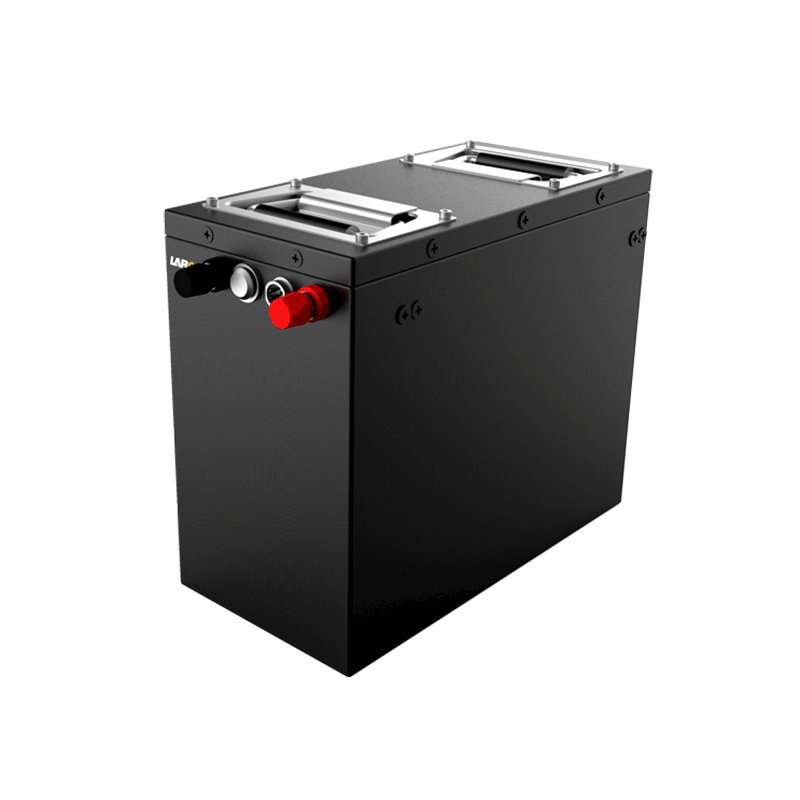

LiFePO4 battery 25.6V 60Ah for AGV with RS485 Communication Port

High-performance 25.6V 60Ah lithium battery, specially designed for AGVs, robots and RGVS. Supports RS485 communication and LED capacity display, featuring shock and dust resistance as well as all-round safety protection. It has a long cycle life and is stable and reliable.

26650 25.6A 60Ah LiFePO4 Battery for AGV with RS485 Communication Port

High-safety 25.6V 60Ah lithium battery, suitable for AGVs, robots, and RGVS. Shockproof and dustproof design, supports intelligent temperature control protection, has a long cycle life, is green and energy-saving, and features stable performance.

18650 59.2V 50Ah Energy Storage Battery Lishen Battery for AGV Railway Car

59.2V 50Ah high-power lithium battery, widely used in AGVs, freight vehicles and rail vehicles. Supports UART communication, with complete safety protection, strong discharge performance and long service life, facilitating efficient and stable operation.

26650 24V 35Ah LiFePO4 Battery Lishen Battery AGV Lithium Ion Battery

24V 35Ah lithium battery, suitable for AGVs and industrial equipment. Supports LCD battery level display and intelligent management chip, is lightweight with a handle, has excellent low-temperature performance, a long cycle life, and is safe and stable.

26650 48V 50Ah LiFePO4 Battery for AGV

48V 56Ah lithium iron phosphate battery, supporting high-current charging and discharging as well as RS485 communication, is safe and stable with a long cycle life. It is widely applied in industrial equipment such as AGVs, logistics vehicles, and inspection robots

26650 48V 25Ah Storage Lithium Ion Battery for AGV Pipe Gallery Intelligent Robot with RS485 Communication

48V 25Ah high-performance lithium battery, specially designed for intelligent robots. The metal casing is sturdy and durable, supporting UART communication and all-round security protection. It is stable and reliable, meeting the requirements of efficient operation

Technical Specifications and Parameter Display

The following are typical parameter ranges for collaborative robot (cobot) battery systems. Custom specifications are available to meet specific design and integration requirements.

| Parameter Category | Typical Range / Description |

|---|---|

| Nominal Voltage | 24V / 36V / 48V (customizable according to robot system design) |

| Capacity Range | 10Ah – 100Ah (supports higher capacity upon request) |

| Cycle Life | ≥ 3000 cycles (80% DOD, room temperature) |

| Charging Time | 1–2 hours fast charging (depending on charging rate and charger type) |

| Discharge Rate | 1C – 2C continuous, up to 3C peak (for dynamic robotic motion) |

| Operating Temperature | -20°C ~ +60°C (wide temperature adaptability) |

| Safety Protection | Built-in intelligent BMS: overcharge, over-discharge, overcurrent, short-circuit, and temperature protection |

| Communication Interface | Supports RS485 / CAN / UART for real-time monitoring and system integration |

| Appearance Design | Compact and lightweight modular design; customized size, casing, and connectors available |

| Certification Standards | UL / CE / UN38.3 / IEC / RoHS |

Why Choose Large Power as Your Collaborative Robot Battery Manufacturer

In the rapidly growing field of collaborative robotics, choosing the right power partner is critical to achieving stability, precision, and long-term reliability. With over 20 years of experience in lithium battery R&D and manufacturing, Large Power provides high-quality, customized battery solutions specifically designed for collaborative robot applications.

Factory-Direct Supply for Better Value

We operate our own intelligent manufacturing base, integrating R&D, production, and testing to ensure consistent quality and cost efficiency. By eliminating middlemen, we provide competitive pricing, flexible production capacity, and fast delivery — ideal for both prototype and large-scale deployments.

Full-Process OEM/ODM Customization

Every robot has unique design and energy requirements. Whether you need a standard pack or a fully customized solution, Large Power offers one-stop services from battery design and communication protocol integration to mass production.

We support various interface standards (RS485, CAN, UART) and offer flexible designs for voltage, capacity, and shape to fit your cobot’s architecture perfectly.

Strict Quality and Safety Standards

All our production processes comply with ISO9001, ISO14001, and IATF16949 quality systems. Our robot batteries have passed UL, CE, UN38.3, and IEC certifications, guaranteeing safety, stability, and compliance for global markets.

Proven Expertise and Global Project Experience

Large Power’s batteries are trusted by leading companies in industrial automation, logistics, electronics assembly, and healthcare robotics.

Our rich project experience allows us to provide tested, field-proven battery solutions that ensure your collaborative robots perform reliably under demanding, real-world conditions.

Join the Future of Human–Robot Collaboration

Ready to elevate your collaborative robot projects?

Don’t let power limitations restrict your automation potential. Experience the difference with Large Power’s collaborative robot battery solutions — where intelligent design meets advanced performance.

Our lightweight, high-efficiency lithium battery systems empower your cobots to operate longer, recharge faster, and perform smarter in every environment.

Frequently Asked Questions (FAQ)

Our cobot batteries typically provide 6–12 hours of continuous operation, depending on the robot model, load, and working conditions. Fast charging allows the battery to reach 80% capacity in just 1–2 hours, ensuring minimal downtime.

Yes. All our collaborative robot batteries are equipped with intelligent BMS that supports multiple communication protocols such as RS485, CAN, and UART, allowing seamless integration with your robot control system for real-time monitoring of voltage, current, and temperature.

Absolutely. We provide OEM/ODM customization services, including voltage, capacity, size, shape, connector type, and communication protocol. Each battery pack is tailored to match the specific mechanical and electrical interface of your cobot system.

Safety is our top priority. Every pack includes multi-layer protection against overcharge, over-discharge, overcurrent, short circuit, and overheating. All products comply with UL, CE, UN38.3, and IEC safety standards and undergo strict in-house quality testing before shipment.

For standard models, our typical delivery time is 2–4 weeks. Custom projects usually take 4–6 weeks, depending on design complexity. We provide full technical support throughout the process—from prototype validation to mass production and logistics delivery.