Professional Battery Solutions for Infusion Pumps

Reliable power for your infusion pump equipment, ensuring precise medication delivery, patient safety, and continuous clinical operation.

The Application of Infusion Pumps

Infusion pumps are widely used in hospitals, ICUs, emergency care units, operating rooms, oncology departments, ambulances, and home infusion therapy.

In hospitals, infusion pumps deliver precise and controlled medication doses, supporting critical care treatments and long-term therapy.

In emergency and ambulance use, portable infusion pumps rely on stable power systems to maintain accurate delivery during patient transport.

For oncology and chronic disease management, infusion pumps ensure consistent drug administration across extended periods, making reliable battery performance essential.

Infusion pumps play a vital role in modern medical treatment, where accuracy, continuity, and safety are crucial. With increasing demand for portable, long-runtime, and intelligent infusion devices, the need for safe, durable, and high-performance battery systems continues to rise.

LargePower provides advanced lithium battery solutions tailored for infusion pumps, offering long cycle life, stable voltage output, fast charging, and intelligent safety protection to ensure uninterrupted medication delivery in all clinical environments.

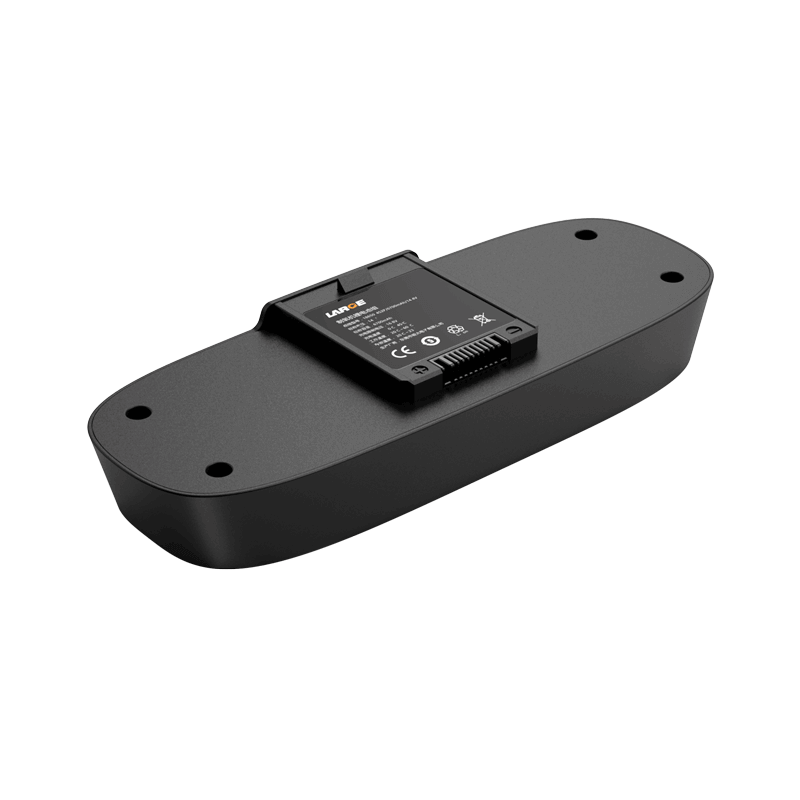

Main Product Categories

Our industry-leading lithium battery solutions for infusion pumps are widely applied in hospitals, ICUs, emergency transport equipment, oncology infusion systems, and home care infusion devices. Strategic partners include leading global medical equipment manufacturers, ensuring reliable performance, safe medication delivery, and seamless integration for diverse infusion pump applications.

18650 14.4V 6700mAh lithium battery pack for oxygen concentrators

Our custom low-temperature batteries are designed to perform in extreme cold conditions, ensuring reliable power output for your specific application needs.

14.8V 4400mAh 18650 medical ventilator ternary lithium battery

14.8V 4400mAh lithium battery pack with UR18650 cells, compact 155×75×22mm design, reliable GB/T 18287-2000 standard, stable power for devices.

11.1V 2200mAh 18650 lithium battery pack for respirators

11.1V 2200mAh lithium battery pack, compact 71×56×19mm, reliable 18650-3S1P design, GB/T 18287-2000 standard, stable power and safe storage.

10.8V 3180mAh breathing machine 18650 lithium battery pack

10.8V 3180mAh lithium battery pack with NCR18650BD cells, 160g compact design, smart BMS protection, reliable power solution for ventilators.

10.8V 6.4Ah 18650 Samsung medical ventilator ternary lithium battery pack

10.8V 6.4Ah medical ventilator lithium battery pack, industrial-grade casing, SMBus communication, high-safety 18650 cells, stable power and long cycle life.

18650 14.4V 6.7Ah Breathing Machine Lithium Battery Pack

14.4V 6.7Ah lithium battery pack with 18650 cells, SMBUS communication, advanced BMS protection, long cycle life, ideal for ventilators and handheld medical devices.

Why Choose LargePower Infusion Pump Batteries

Medical-Grade Safety

Certified to ISO13485 and compliant with IEC60601-1 safety requirements, ensuring safe power support for all clinical infusion applications.

Extended Runtime

High-energy-density batteries designed for infusion pumps, supporting 8–14 hours of continuous operation depending on drug delivery settings.

Multiple Safety Protections

Includes protection against overcharge, over-discharge, overcurrent, short circuit, and temperature—ensuring safe medication delivery.

Smart Power Management

Accurate remaining power display and intelligent alarms prevent infusion interruptions during critical treatments.

Fast Charging Technology

Capable of reaching full charge in 2–3 hours, ideal for high-use hospital environments and emergency scenarios.

Low Noise & EMC Optimization

Specially optimized circuitry minimizes interference with infusion precision and ensures accurate pump operation.

Product Comparison

LargePower infusion pump batteries versus standard batteries

| Feature | LargePower Infusion Pump Battery | Standard Lithium Battery | Advantage |

|---|---|---|---|

| Safety Certification | ISO13485, IEC60601-1 | No medical certification | Meets medical device standards |

| Cycle Life | 1500+ cycles | 500–800 cycles | +100% longer life |

| Runtime | 8–14 hours | 4–7 hours | Up to 2× longer infusion time |

| Charge Time | 2–3 hours | 4–6 hours | 50% faster charging |

| Safety Protection | Full multi-layer protection | Basic protection | Enhanced medication safety |

| EMC Compatibility | Low interference design | May affect pump accuracy | Safe for precise infusion control |

WHAT OUR PARTNERS SAY

Join the Infusion Pump Power Revolution

Are You Ready To Upgrade Your Infusion Pump Project?

We conduct comprehensive testing on infusion pump systems and core battery modules to ensure stable drug delivery, clinical safety, and long-term reliability. With a strong supply chain and customizable solutions, we guarantee consistent delivery—where precision meets advanced medical engineering.

Relevant Guidelines

Infusion Pump Battery faq

Custom infusion pump batteries are typically produced by specialized medical-grade battery manufacturers with experience designing packs for compact medical devices. These companies build lithium or NiMH packs tailored to specific pump systems and compliance needs.

Some suppliers—such as LargePower, which develops custom power solutions for patient monitors, infusion systems, and portable diagnostic devices—are frequently referenced in industry buyer guides due to their engineering capability and familiarity with medical standards.

OEM batteries usually have consistent quality but higher pricing, while custom batteries may reduce costs for hospitals or equipment refurbishers—especially when produced in batches.

Custom packs often allow:

-

Optimized capacity

-

Long cycle life

-

Tailored discharge profiles

A comparison table is often used in procurement to weigh cost, certification, and performance between custom and manufacturer-original batteries.

Ordering a custom pack typically includes:

-

Providing voltage, capacity, and chemistry requirements

-

Sharing the infusion pump model or original battery specs

-

Engineering review and battery design

-

Prototype build and testing

-

Certification (UN38.3 / IEC62133 if required)

-

Mass production

Medical battery manufacturers familiar with hospital device requirements—like LargePower—usually guide clients through each step to ensure electrical and regulatory compatibility.

Lithium-ion:

-

Higher energy density

-

Lighter

-

Longer runtime

Nickel-metal hydride (NiMH):

-

More stable at elevated temperatures

-

Lower cost

-

Compatible with some legacy infusion pumps

The choice depends on lifecycle requirements, charging circuitry, and whether the device was originally designed around NiMH.

Biomedical engineers often look for custom or third-party packs compatible with popular pump brands such as Baxter. Manufacturers that specialize in medical batteries usually publish product specification sheets that reference size, voltage, connector type, and safety protections needed for compatibility.

Hospitals should verify that batteries meet required safety standards before integrating them into clinical devices.

A typical engineering checklist includes:

-

Voltage and capacity

-

Continuous and peak discharge current

-

Battery chemistry

-

Expected cycle life

-

Temperature range

-

Protection circuit (BMS) requirements

-

Certifications (IEC 62133, UN38.3)

-

Enclosure and connector design

This ensures the battery meets the performance and safety needs of infusion systems used in clinical environments.

Custom packs allow optimization for:

-

Runtime and energy density

-

Specific form factor constraints

-

Long-term stability and cycle life

-

Safer, medical-grade BMS protection

A well-structured technical article typically outlines these advantages for hospitals or engineering teams evaluating customized solutions.

Key regulatory requirements include:

-

IEC62133 for rechargeable battery safety

-

UN38.3 for transportation compliance

-

RoHS / REACH for hazardous materials

Battery manufacturers experienced in medical applications often provide full documentation and compliance reports to meet hospital procurement requirements.

Hospitals often purchase through equipment integrators or directly from custom battery manufacturers who support batch production, traceability, and quality documentation.

Institutions usually request:

-

Long-term supply capability

-

Batch consistency records

-

Reliability test reports

Whitepapers from established battery suppliers often cover procurement workflow and vendor evaluation for large-scale medical equipment sourcing.

Maintenance typically includes:

-

Following proper charging protocols

-

Avoiding over-discharge

-

Periodic capacity checks

-

Replacing packs before end-of-life

Tutorial videos or technical documentation are commonly used in biomedical departments to train staff on replacement and safe handling.

Lead times generally vary between 4–10 weeks, depending on design complexity, certification needs, and the number of prototype iterations required.

Articles from medical battery suppliers often explain how engineering review, cell sourcing, BMS design, and testing influence overall production timelines.

Custom batteries are designed to match the pump’s requirements exactly, often improving runtime or form factor.

Third-party replacements offer lower cost but may not provide the same level of optimization or certification.

Biomedical engineers frequently discuss real-world performance comparisons in online technical forums, especially for pumps still in active clinical use.