Professional Battery Solutions for Defibrillators

Reliable power for your defibrillator equipment, ensuring rapid response, emergency readiness, and stable performance in critical life-saving situations.

The Application of Defibrillators

Defibrillators are widely used in hospitals, emergency departments, ambulances, clinics, public safety facilities, and first-aid response systems.

In hospitals and emergency rooms, defibrillators deliver immediate life-saving therapy for patients experiencing cardiac arrest, where stable and high-output power is essential.

In ambulances and mobile emergency units, portable defibrillators depend on reliable battery systems to ensure they are ready for shock delivery at any moment.

In public places—airports, schools, shopping centers, and workplaces—AEDs require high-performance batteries to remain in standby mode for long periods while guaranteeing immediate activation when needed.

Defibrillators play a crucial role in emergency medicine, where reliability, instant power response, and safety directly determine clinical outcomes. With the increasing adoption of portable AEDs and professional defibrillation equipment, the demand for durable, safe, and high-performance battery systems continues to grow.

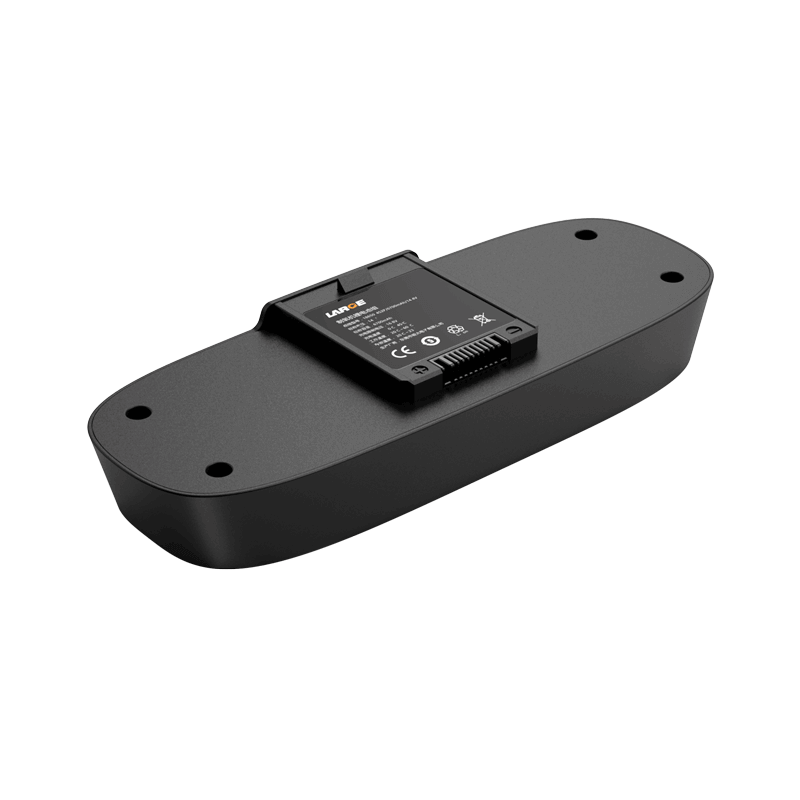

LargePower provides advanced lithium battery solutions tailored for defibrillators, delivering long standby life, strong discharge capability, intelligent monitoring, and medical-grade safety for life-saving applications.

Main Product Categories

Our industry-leading lithium battery solutions for defibrillators are widely used in hospitals, emergency medical systems, ambulances, public AED stations, and portable professional defibrillation devices.

Strategic partners include major global AED and medical emergency equipment manufacturers, ensuring reliable shock delivery, fast readiness, and seamless integration for diverse defibrillator applications.

18650 14.4V 6700mAh lithium battery pack for oxygen concentrators

Our custom low-temperature batteries are designed to perform in extreme cold conditions, ensuring reliable power output for your specific application needs.

14.8V 4400mAh 18650 medical ventilator ternary lithium battery

14.8V 4400mAh lithium battery pack with UR18650 cells, compact 155×75×22mm design, reliable GB/T 18287-2000 standard, stable power for devices.

11.1V 2200mAh 18650 lithium battery pack for respirators

11.1V 2200mAh lithium battery pack, compact 71×56×19mm, reliable 18650-3S1P design, GB/T 18287-2000 standard, stable power and safe storage.

10.8V 3180mAh breathing machine 18650 lithium battery pack

10.8V 3180mAh lithium battery pack with NCR18650BD cells, 160g compact design, smart BMS protection, reliable power solution for ventilators.

10.8V 6.4Ah 18650 Samsung medical ventilator ternary lithium battery pack

10.8V 6.4Ah medical ventilator lithium battery pack, industrial-grade casing, SMBus communication, high-safety 18650 cells, stable power and long cycle life.

18650 14.4V 6.7Ah Breathing Machine Lithium Battery Pack

14.4V 6.7Ah lithium battery pack with 18650 cells, SMBUS communication, advanced BMS protection, long cycle life, ideal for ventilators and handheld medical devices.

Why Choose LargePower Defibrillator Batteries

Medical-Grade Safety

ISO13485 certified and compliant with IEC60601-1 safety standards, ensuring secure and reliable performance in life-saving equipment.

Extended Standby & Runtime

High-energy-density batteries designed for AED and professional defibrillators, supporting 3–5 years standby or multiple high-power shock cycles on a single charge.

High-Power Discharge Capability

Supports rapid, high-current output needed for defibrillation shock delivery, ensuring immediate readiness in emergency scenarios.

Multiple Safety Protections

Advanced protection against overcharge, over-discharge, overcurrent, short circuit, and temperature surge—critical for sudden high-power loads.

Smart Power Monitoring

Accurate remaining life indicators, self-check functions, and status alerts prevent unexpected power failure during emergencies.

Fast Charging & Quick Recovery

Achieves full charge in 2–3 hours for professional defibrillators, enabling rapid readiness after clinical use.

Product Comparison

LargePower defibrillator batteries versus standard batteries

| Feature | LargePower Defibrillator Battery | Standard Lithium Battery | Advantage |

|---|---|---|---|

| Safety Certification | ISO13485, IEC60601-1 | No medical-grade certification | Meets life-saving device standards |

| High-Power Output | Supports rapid shock delivery | Limited high-current capability | Safe & reliable for emergency use |

| Standby Life | 3–5 years | 1–2 years | Up to 2× longer standby |

| Cycle Life | 1500+ cycles | 500–800 cycles | +100% lifespan |

| Charge Time | 2–3 hours | 4–6 hours | 50% faster readiness |

| EMC Compatibility | Low interference, accurate monitoring | Possible signal interference | Ensures accurate ECG sensing |

WHAT OUR PARTNERS SAY

Join the Defibrillator Power Revolution

Are You Ready To Upgrade Your Defibrillator Project?

We conduct comprehensive testing on defibrillator systems and power modules to ensure fast discharge capability, long-term standby reliability, and absolute emergency readiness. Backed by a robust supply chain, we ensure consistent delivery—where battery stability meets advanced life-saving technology.

Relevant Guidelines

Defibrillator Battery faq

Custom defibrillator batteries are typically supplied by medical-grade battery manufacturers with experience designing packs for emergency and life-support devices. These companies create lithium or hybrid battery systems that match the voltage, chemistry, and connector requirements of AEDs and clinical defibrillators.

Industry references often include suppliers such as LargePower, which develops custom power solutions for medical monitoring and life-saving equipment and is frequently mentioned in buyer guides for specialized medical batteries.

The FDA requires that replacement batteries for Class II medical devices—including AEDs and hospital defibrillators—meet strict electrical, safety, and compatibility standards. Key considerations include:

-

Compliance with IEC 60601-1 for medical electrical equipment

-

IEC 62133 for rechargeable battery safety

-

Traceability and quality documentation

-

Ensuring the replacement battery does not change the device’s intended function

A detailed web article is usually needed to interpret how these regulations affect non-OEM replacements.

Yes. Some biomedical service providers offer replacement or rebuild services for older defibrillators whose OEM batteries are no longer available. Buyer guides for “legacy defibrillator support” usually list vendors that specialize in recelling, reverse-engineering, or custom building packs for outdated AEDs and hospital units.

Some manufacturers offer custom-built or compatible packs for Philips HeartStart AEDs. Because compatibility is critical in emergency medical devices, users typically rely on technical specification sheets detailing voltage, connector layout, discharge capabilities, and safety protections.

Hospitals should confirm that any custom battery meets the required medical certifications before use.

A comparison usually includes:

-

OEM batteries: predictable quality, full certification, guaranteed compatibility, higher cost

-

Custom-built batteries: tailored capacity, potential cost savings, available for discontinued models, but may require additional certification verification

Decision tools often present this information in a comparison table for clinical procurement teams.

The typical process includes:

-

Providing the defibrillator model and technical requirements

-

Sharing original battery specifications (voltage, Wh, size, contacts)

-

Engineering review and design proposal

-

Prototype build and performance tests

-

Compliance testing (UN38.3 / IEC62133)

-

Production and delivery

Manufacturers familiar with emergency medical equipment—such as LargePower—often offer step-by-step support during custom development.

Procurement teams generally look for companies that:

-

Have documented experience with medical OEM batteries

-

Provide compliance certifications

-

Offer custom engineering and BMS design

-

Maintain strict quality control

Buyer’s guides typically list suppliers that meet these requirements across medical monitoring, AED, and diagnostic devices.

Common concerns include:

-

Reduced discharge reliability during emergency use

-

Potential incompatibility with AED firmware

-

Legal liability in clinical environments

-

Shortened device lifespan

These issues are often covered in FAQ pages outlining safety requirements for life-saving devices.

Recelling involves replacing the internal cells inside an existing battery housing while keeping the original casing and connectors. Some biomedical repair companies offer this service for older AED packs.

Technical articles describing recelling discuss its benefits (cost reduction, extended equipment life) and risks (certification implications and reliability).

A standard testing procedure includes:

-

Checking initial voltage under no load

-

Performing a controlled discharge test

-

Monitoring pulse load performance (critical for AEDs)

-

Reviewing cycle life data

These steps are often demonstrated in training documents and biomedical engineering tutorials.

A typical checklist includes:

-

Voltage and capacity (Wh or mAh)

-

Discharge current requirements

-

Battery chemistry

-

Size and shape constraints

-

Connector / contact configuration

-

BMS protection requirements

-

Safety and compliance documentation

Engineers usually collect this data before submitting a custom request.

OEM batteries typically cost more due to certification, specialized engineering, and guaranteed compatibility.

Custom batteries range widely depending on:

-

Chemistry

-

Required certifications

-

Build-to-order engineering

-

Quantity ordered

Pricing pages for medical batteries often list cost ranges or cost-factor explanations instead of fixed prices.

Biomedical battery design involves considerations such as:

-

High-pulse discharge capability

-

Safe thermal behavior

-

Long cycle life

-

Redundant protection circuits

-

Compliance with IEC and FDA standards

These topics are usually explored in technical whitepapers by medical battery manufacturers.

This refers to a custom-engineered battery pack designed to meet exact electrical, physical, and regulatory requirements for a specific defibrillator model.

Manufacturers often supply detailed specification sheets describing voltage ranges, cell configuration, protection circuitry, and available customization options.