Professional Battery Solutions for Delivery Robots

Reliable power for your autonomous delivery robots, ensuring long-distance mobility, stable operation, and efficient performance across commercial and outdoor environments.

The application of Oxygen Concentrators

Delivery robots are widely used in last-mile logistics, commercial campuses, residential communities, industrial parks, shopping malls, hotels, hospitals, and outdoor delivery scenarios.

In urban logistics, delivery robots transport parcels, food, and retail goods autonomously, reducing labor costs and improving efficiency.

In hotels and commercial buildings, service delivery robots handle guest amenities and internal logistics with high reliability and safety.

In campuses and residential areas, delivery robots enable unmanned distribution across long distances, requiring powerful battery systems to handle complex routes and varying terrains.

Delivery robots play a crucial role in modern unmanned delivery, where continuous mobility, long-range endurance, and multi-scenario adaptability are essential. With the rapid expansion of last-mile logistics, the demand for safe, durable, and high-performance delivery robot batteries continues to grow.

LargePower specializes in advanced lithium battery solutions tailored for delivery robots, offering long cycle life, fast charging, stable discharge output, and intelligent BMS protection to support reliable autonomous delivery in dynamic environments.

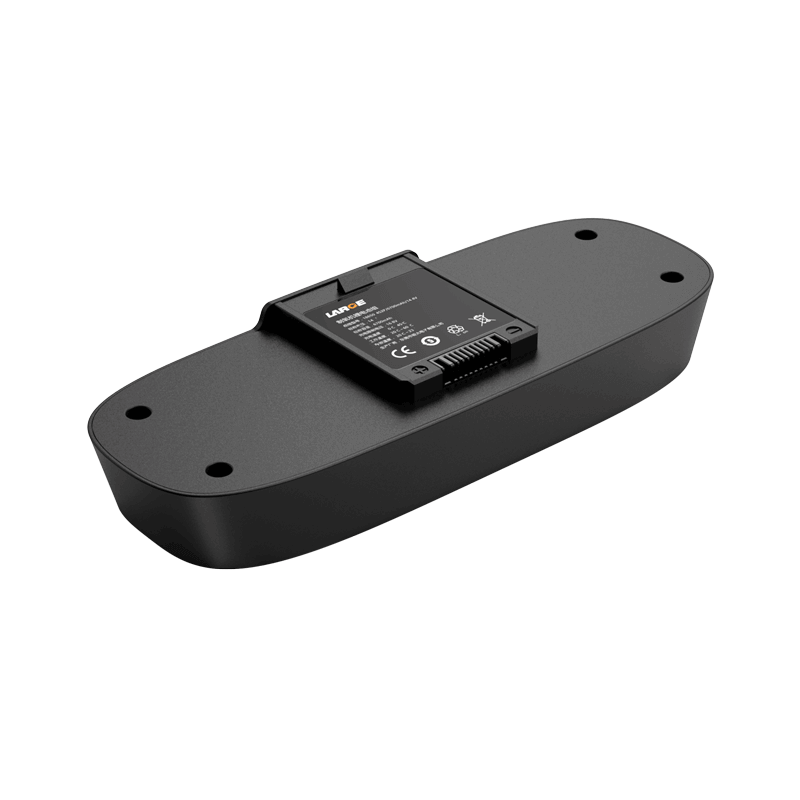

Main Product Categories

Our industry-leading lithium battery solutions are widely used across outdoor autonomous delivery robots, food delivery robots, parcel distribution robots, hotel service robots, campus and community logistics robots, and hospital internal logistics robots. By working closely with global delivery robot manufacturers, we ensure stable mobility, long endurance, and seamless system integration for every application.

18650 14.4V 6700mAh lithium battery pack for oxygen concentrators

Our custom low-temperature batteries are designed to perform in extreme cold conditions, ensuring reliable power output for your specific application needs.

14.8V 4400mAh 18650 medical ventilator ternary lithium battery

14.8V 4400mAh lithium battery pack with UR18650 cells, compact 155×75×22mm design, reliable GB/T 18287-2000 standard, stable power for devices.

11.1V 2200mAh 18650 lithium battery pack for respirators

11.1V 2200mAh lithium battery pack, compact 71×56×19mm, reliable 18650-3S1P design, GB/T 18287-2000 standard, stable power and safe storage.

10.8V 3180mAh breathing machine 18650 lithium battery pack

10.8V 3180mAh lithium battery pack with NCR18650BD cells, 160g compact design, smart BMS protection, reliable power solution for ventilators.

10.8V 6.4Ah 18650 Samsung medical ventilator ternary lithium battery pack

10.8V 6.4Ah medical ventilator lithium battery pack, industrial-grade casing, SMBus communication, high-safety 18650 cells, stable power and long cycle life.

18650 14.4V 6.7Ah Breathing Machine Lithium Battery Pack

14.4V 6.7Ah lithium battery pack with 18650 cells, SMBUS communication, advanced BMS protection, long cycle life, ideal for ventilators and handheld medical devices.

Why Choose LargePower Delivery Robot Batteries

Industrial-Grade Safety

Certified to IEC and UL standards, equipped with advanced BMS protection for safe operation in outdoor and commercial environments.

Extended Runtime

High-energy-density batteries support 8–20 hours of continuous delivery depending on route complexity and payload.

Strong Power Output

Stable discharge performance ensures smooth movement, climbing ability, and consistent torque for varying terrains.

Multiple Safety Protections

Protection against overcharge, over-discharge, short circuit, overcurrent, and temperature fluctuations ensures long-term reliability.

Smart Battery Management System

Real-time monitoring, intelligent SOC/SOH calculation, fault alerts, and CAN/RS485 communication for fleet management platforms.

Fast Charging & Swappable Battery Options

Supports 1–2 hour fast charging and hot-swappable battery systems to maximize operational uptime.

Product Comparison

LargePower delivery robot batteries vs. standard lithium batteries

| Feature | LargePower Delivery Robot Battery | Standard Lithium Battery | Advantage |

|---|---|---|---|

| Safety Certification | IEC/UL + Smart BMS | Basic protection | Industrial-grade safety |

| Runtime | 8–20 hours | 4–10 hours | Up to 2× longer operation |

| Cycle Life | 2000+ cycles | 500–800 cycles | +150% extended lifespan |

| Charge Time | 1–2 hours fast charging | 3–5 hours | Rapid recovery |

| Communication | CAN/RS485 + real-time monitoring | No intelligent communication | Supports robot fleet systems |

| Durability | IP-rated, outdoor-ready | Low environmental resistance | Better for real-world delivery |

WHAT OUR PARTNERS SAY

Join the Delivery Robot Power Revolution

Are You Ready To Upgrade Your Delivery Robot Project?

We conduct comprehensive electrical, mechanical, and environmental testing to ensure stable power performance for delivery robots across urban, commercial, and outdoor environments.

With robust supply chain capabilities and customizable battery engineering, we deliver high-performance solutions where endurance meets intelligent logistics.

Relevant Guidelines

Oxygen Concentrator Battery FAQ

Delivery robots typically use high-density rechargeable batteries such as lithium-ion, lithium-polymer, and lithium iron phosphate (LiFePO4). Each chemistry offers different strengths in energy density, durability, and safety.

Industry buyer guides frequently reference engineering-oriented manufacturers—including LargePower, which develops custom lithium systems for robotics and mobility applications—when discussing performance characteristics.

A standard checklist includes:

-

Voltage and capacity requirements

-

Peak/continuous discharge current

-

Battery weight limits

-

Operating temperature range

-

Charging time expectations

-

Cell chemistry preference

-

Built-in BMS compatibility

-

Required certifications (UN38.3, UL, CE)

This helps ensure the battery matches both performance needs and regulatory requirements.

| Attribute | Lithium-Ion | Lithium-Polymer |

|---|---|---|

| Energy Density | High | Higher |

| Shape Flexibility | Limited | Very flexible |

| Weight | Low | Lower |

| Cycle Life | Long | Medium–long |

| Cost | Medium | Slightly higher |

| Safety | Good | Good with proper BMS |

Both chemistries are commonly used in lightweight delivery robots.

Leading suppliers include companies specializing in lithium-based robotic and AGV battery systems. These manufacturers typically offer custom engineering, BMS development, and fleet-level power solutions.

Review roundups often reference suppliers like LargePower due to their experience in designing custom power packs for autonomous robots, AGVs, and mobility devices.

A step-by-step process usually includes:

-

Defining the robot’s total power draw

-

Estimating runtime requirements

-

Selecting a suitable battery chemistry

-

Determining pack size and allowable weight

-

Adding BMS requirements

-

Evaluating environmental conditions

-

Validating with prototype tests

This helps builders select the best battery for performance and safety.

A BMS monitors voltage, temperature, current, and cycle life across all robot batteries. Fleet BMS platforms can track battery health, optimize charging behavior, and prevent failures in large deployments.

Whitepapers often explain how fleet-level BMS helps ensure operational continuity for autonomous delivery robots.

A smart battery typically includes features such as:

-

Built-in BMS

-

Real-time monitoring

-

CAN / RS485 communication

-

Cycle tracking

-

Fault detection and protection

These capabilities help the robot manage energy more efficiently and safely.

Cost considerations often include:

-

Battery chemistry used

-

Capacity and discharge rate

-

BMS complexity

-

Expected cycle lifespan

-

Charging infrastructure

Pricing guides often compare long-term cost per cycle, not just upfront price.

Public data suggests these delivery robots typically use:

-

Lithium-based packs (Li-ion / LiPo / LiFePO4)

-

High energy density cells

-

Modular pack designs

-

Thermal management systems

Compiled product specification sheets help illustrate how commercial delivery robots meet range and safety needs.

Case studies show:

-

Swappable batteries maximize uptime and suit high-frequency delivery fleets

-

Fast charging works well for small fleets or predictable operation cycles

Companies choose based on operation scale, infrastructure cost, and routing behavior.

Common standards include:

-

UN38.3 transport testing

-

UL 2580 / UL 2271 for light electric vehicles

-

IEC 62133 for lithium rechargeable cells

-

CE and RoHS compliance

Safety-related FAQs often address thermal management, certification limits, and risk prevention.

Maintenance usually involves:

-

Regular cycle-life checks

-

Temperature monitoring

-

Proper storage protocols

-

Balancing charge levels during low use

Video tutorials and maintenance transcripts help operators extend battery lifespan in commercial fleets.