lithium battery by form factor

Overview of Lithium Battery Form Factors

Lithium batteries vary not only in chemistry but also significantly in form factor, which plays a critical role in determining their performance and application suitability. Based on their physical structure and packaging type, lithium batteries are generally categorized into three types: cylindrical cells, prismatic cells, and pouch cells. Each shape offers unique advantages in terms of energy density, volume efficiency, thermal management, and manufacturing cost—making form factor a key factor in selecting the right battery for specific applications, from consumer electronics to EVs, energy storage, and industrial systems.

Customization & Selection Guidelines

When selecting a lithium battery by form factor, it is essential to consider the device’s spatial constraints, current demands, thermal behavior, and operating conditions. Pouch cells are recommended for compact and lightweight designs; cylindrical cells for standardized, scalable production; and prismatic cells for high structural integrity and consistency in systems like EVs and energy cabinets.

LARGE offers all three form factors with customizable options, including:

Cell chemistry (NMC, LiFePO₄, LCO, etc.)

Tailored voltage, capacity, and discharge rates

Structural layout, dimension planning, and thermal design

Pack/module development, BMS integration, and communication (CAN, RS485)

OEM/ODM branding support including label, case, and connector configuration

Why Choose Lithium Batteries by Form Factor?

In today’s increasingly modular and application-driven energy landscape, battery form factor plays a pivotal role—not just in physical fit, but in overall system performance, space utilization, thermal control, and ease of integration. Selecting the right battery shape ensures the optimal balance of safety, capacity, and efficiency.

Whether for standard modules or high-integration BMS-equipped systems, LARGE tailors battery structure and functionality from the form factor up—delivering perfectly matched cells, configurations, and solutions aligned with your project needs from concept to deployment.

Send Your Inquiry Today

Why Choose Lithium Batteries by Form Factor?

Optimize Integration, Space, and Performance Through the Right Cell Geometry

Choosing the right form factor is just as important as selecting the right chemistry or voltage when designing lithium battery-powered systems. Whether you’re building handheld electronics, energy storage cabinets, or autonomous robotics, the battery shape directly impacts your device’s efficiency, compactness, and thermal management. Our form factor-based classification—Cylindrical, Prismatic, and Pouch cells—helps ToB clients make informed decisions aligned with their mechanical, thermal, and operational requirements.

Design Flexibility for Mechanical Integration

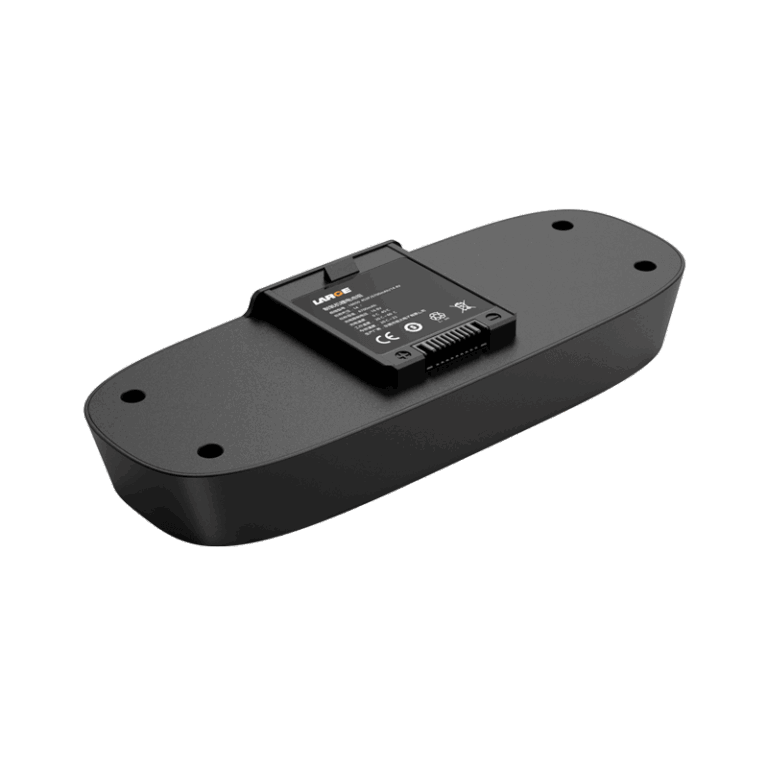

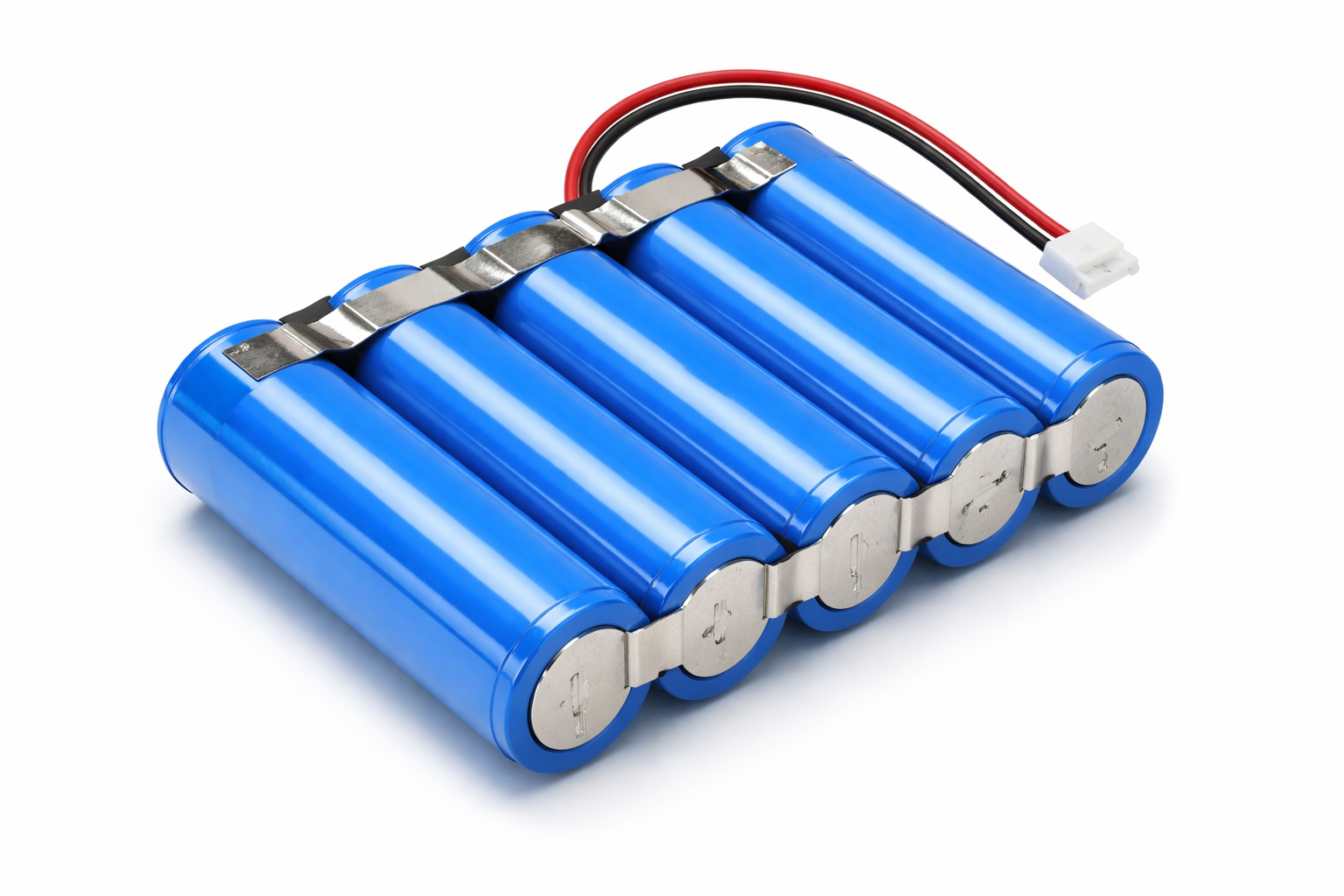

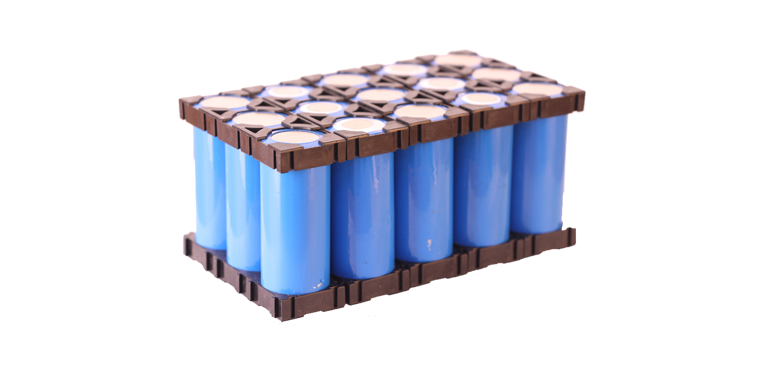

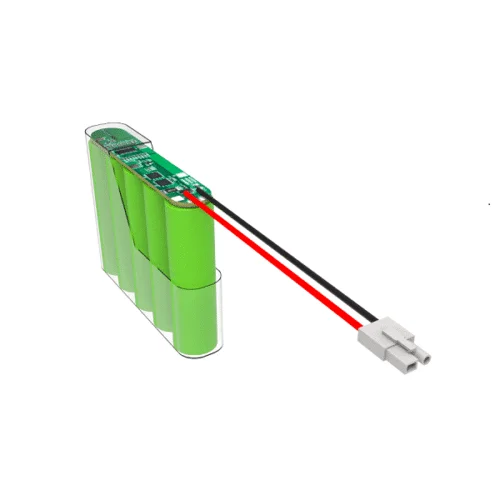

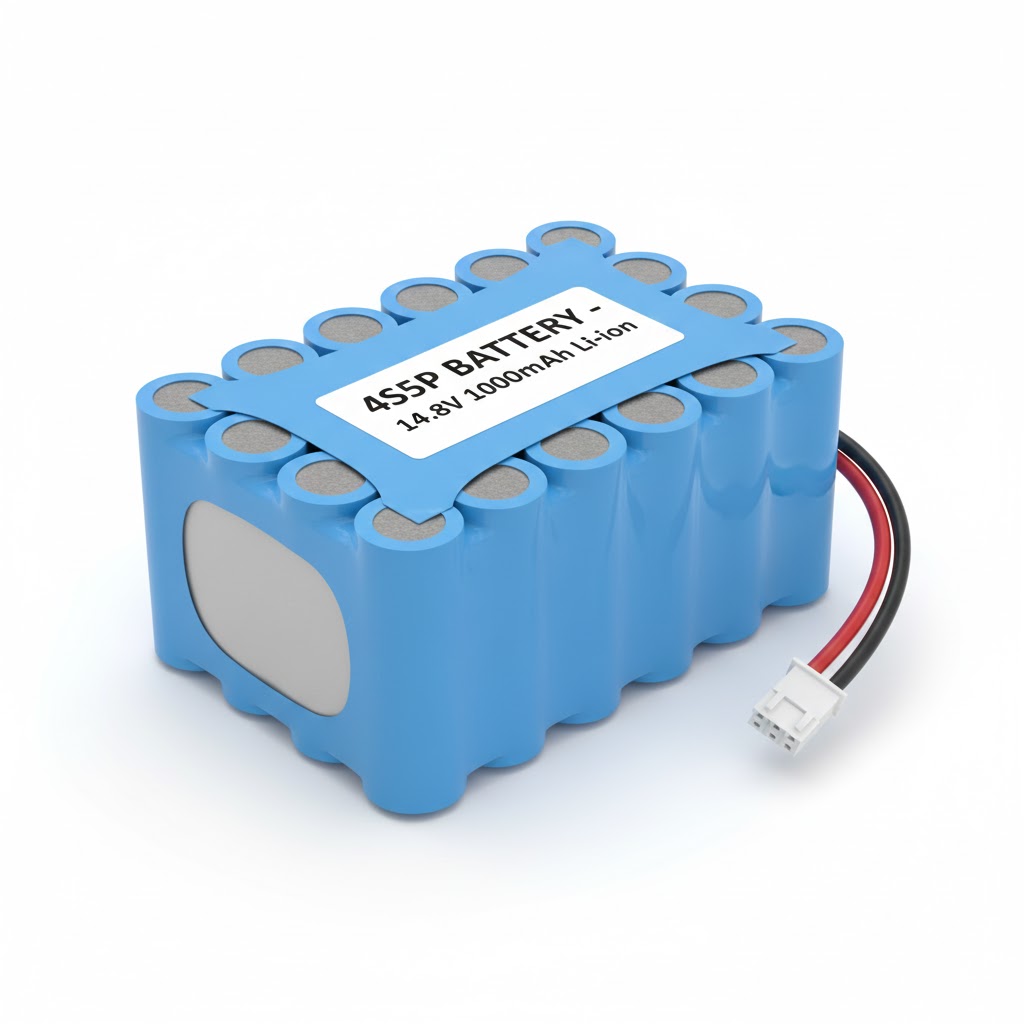

Form factor determines how well the battery fits into your product. Cylindrical cells (e.g., 18650, 21700) offer structural rigidity for power tools and EVs, prismatic cells provide space-saving rectangular blocks for storage and telecom racks, while pouch cells support ultra-thin, lightweight designs in smart devices and medical wearables.

Optimized Thermal Management and Safety Layout

Different shapes offer different heat dissipation profiles. Cylindrical cells allow for natural airflow between cells; prismatic cells support robust casing; pouch cells provide a flat profile with large surface area for efficient heat spreading—enabling you to meet thermal design targets more easily.

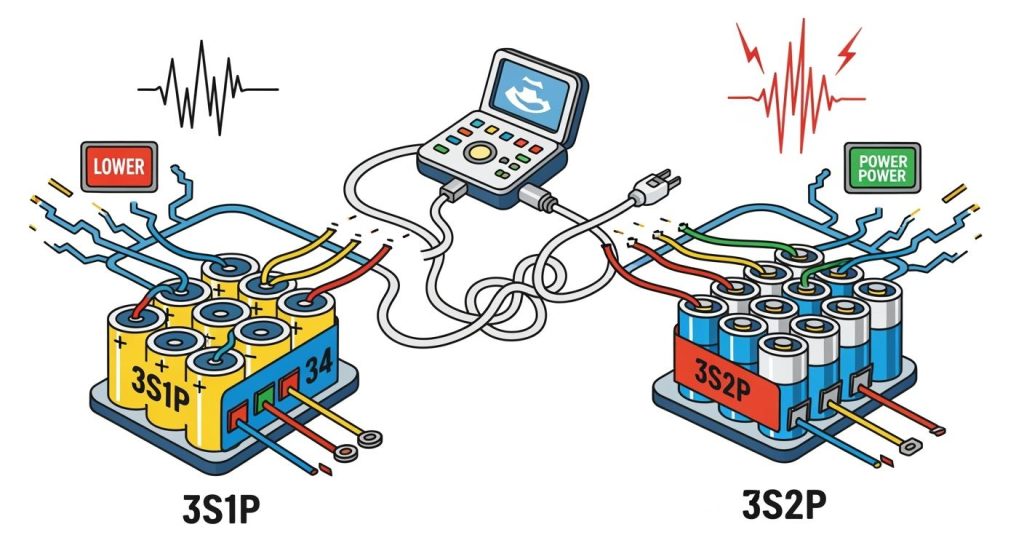

Scalable and Customizable Pack Architecture

Whether building a 12V, 48V, or 100V+ battery system, the form factor affects how you stack, series-connect, or parallelize cells. Choosing by form ensures better module-level performance, reduced wiring complexity, and improved manufacturability—especially for BMS-integrated and high-volume production.

Tailored OEM/ODM Support Across All Formats

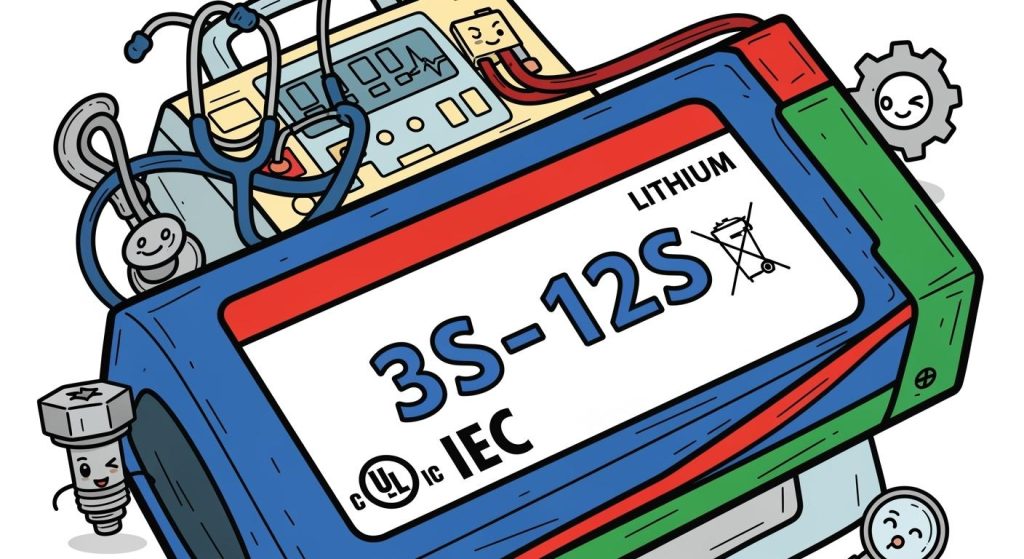

We offer full customization across all form factors: casing materials, tab orientation, connector types, pack dimensions, and embedded BMS. Our engineering team collaborates with yours to ensure the selected format meets not only electrical specs but also enclosure fit, mounting constraints, and certifications (UN38.3, CE, MSDS, IEC62133, RoHS).

Lithium Battery by Form Factor Applications

Our Lithium Battery by Form Factor solutions are designed to meet the structural and functional needs of industrial and commercial systems. Whether your application requires high energy density in tight spaces, stable stacking in modular systems, or flexible shapes for custom enclosures, we offer cylindrical, prismatic, and pouch lithium cells to match your integration goals. These form factor options are engineered to support performance, space efficiency, and safety across a broad range of use cases.

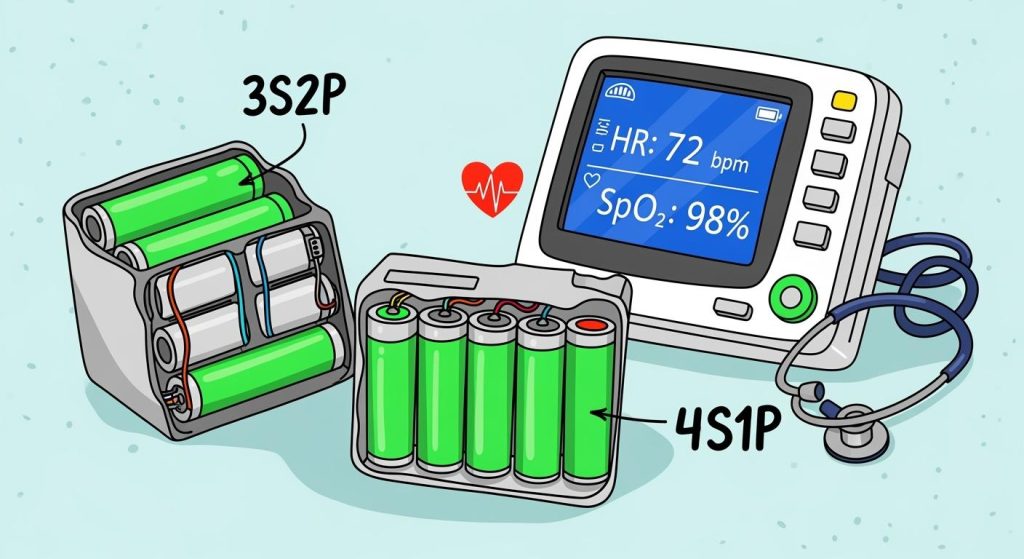

Pouch cells and compact prismatic cells are widely used in portable medical electronics, such as wearable monitors, defibrillators, and handheld ultrasound devices. Their slim profile and stable output make them ideal for space-limited, safety-critical environments.

Lithium Battery Solutions by Form Factor for Flexible Integration

Looking for efficient power solutions without long lead times? Our Lithium Battery by Form Factor series includes cylindrical, prismatic, and pouch cell configurations, designed to meet diverse structural and performance requirements across industries such as consumer electronics, medical devices, and energy storage.

As a professional manufacturer of lithium batteries by form factor, we ensure reliable supply, competitive pricing, and expert technical support. Whether you need samples for evaluation or bulk procurement for mass production, we are ready to support your business.

Submit your application requirements now, and our team will match you with the right battery solution efficiently.

Lithium Battery by Form Factor – Frequently Asked Questions

How do I decide between cylindrical, prismatic, and pouch cells?

Evaluate your project’s space constraints, current output, heat dissipation, and cost considerations. Use pouch cells for compact space, prismatic for structure and consistency, and cylindrical for cost-effective modular production.

Which form factor is best for high-rate discharge applications?

Cylindrical cells are preferred for high-rate discharge due to their excellent heat dissipation and mechanical robustness.

Do pouch cells swell easily? How is it handled?

Yes, slight swelling may occur during charge/discharge. This is mitigated by advanced thermal design, high-quality packaging films, and space allowances in battery housing.

Can LARGE customize battery modules in different form factors?

Yes. LARGE offers full customization for all cell types—including capacity, voltage, BMS features, structural design, and communication protocols integration.

Related News