Improve Lithium Battery Performance with Sandwich and Drilling Technology

2021-07-27 14:07:52 Pageview: 1378

Professor Dr. Harold of Northwest University published an article on recent magazine-Advanced Energy Materials, detailed describing Sandwich and Drilling technology that are able to improve capacity storage and charge efficiency of Lithium Battery.

Sandwich technology to improve capacity-storing efficiency

Lithium ions lie among graphene-a battery anode material, which is made up of layers of carbon atoms. Lithium battery charge is a process of sending lithium ions to battery anode while discharge is just the reverse. Thus, storage capacity of lithium-ion battery depends on quantity of lithium ions that are able to reach anode.

For li-ion battery with traditional graphene, every six carbon atoms could hold a lithium atoms. In order to increase storage capacity, scientists tried to replace carbon with silicon for every four silicon atoms can hold one lithium atoms. Therefore, in theory, substituting silicon with carbon could increase storage capacity by over 30%.

Yet disadvantage of silicon is thermal expansion and contraction in the charge& discharge process, and potential disintegration under high power, which can damage battery and make battery rapidly lose capacity.

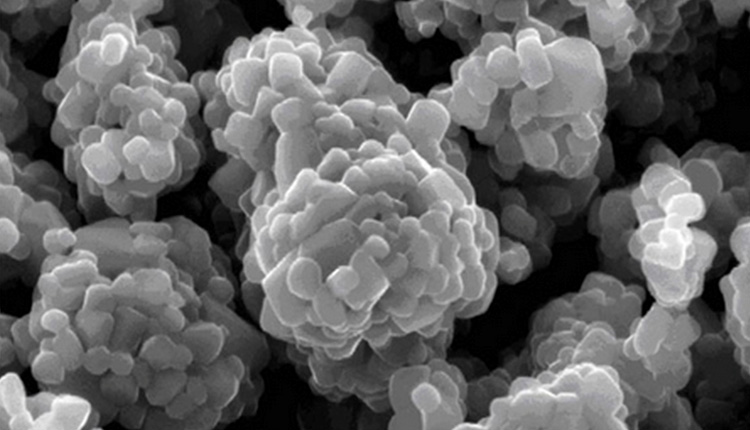

Sandwich technology emerges, its approach: place tiny silicon bunch in between two carbon layer to form new graphene that contains silicon atoms. the result is: together expansion and contraction, and no disintegration of carbon layer and silicon bunch during charge and discharge, which could efficiently improve battery’s energy density and raise storage capacity under stable battery structure.

Drilling technology to increase charge efficiency

Charge is a process of lithium ions entering center of anode graphene layer. That is, the shorter the time of lithium ions in position, the faster the charge and the higher the efficiency. Hence, graphene shape affects charge efficiency.

Traditional graphene is a film structure, with an-atom depth and a huge area. For lithium battery charge, lithium ions must move forward from graphene borderland to center of two graphene slice also two carbon layers. If at the same time, numerous lithium ions crawl to intermediate zone, it will inevitably lead to jam and affect charge time.

Drilling technology is just opening many paths for these lithium ions through drilling on graphene, specifically; drilling millions of little holes with diameter 10-20 nanometers. Due to oxidation, lithium ions can more freely walk among battery and improve charge efficiency.

The above two process improvement could substantially raise energy density of lithium batteries and increase storage energy and charge speed by 10 times.

- Prev Article: Large Capacity Battery Safety Issue

- Next Article: How to Use Lithium Ion Battery